Case Study

HI TOOL™ tackles lateral and torsional vibrations in problematic slim-hole underreaming application

Contact

In Brief

Expro’s Harmonic Isolation technology (HI Tool™) boosts underreaming efficiency by significantly reducing stick-slip by 80% and drilling double the meterage of offset well with decent controlled ROP

Product Line

Region

Customer Challenges

- Expro was contacted by Schlumberger (SLB) Australia to support their current project with a customer where they provided directional drilling services

- The customer was experiencing severe vibrations in the two wells in the same sections where underreamers were utilized for small ratio hole opening (6” x 6-3/4” and 6” x 7”)

- The vibration dynamics generated by having multiple cutting structures in the BHA, hampers drilling performance; reduced rate of penetration and footage drilled while negatively affecting BHA durability

- Expro’s Harmonic Isolation Tool (HI TOOL™) has a good track record performance in country in mitigating vibration in multiple BHA applications

Expro Excellence

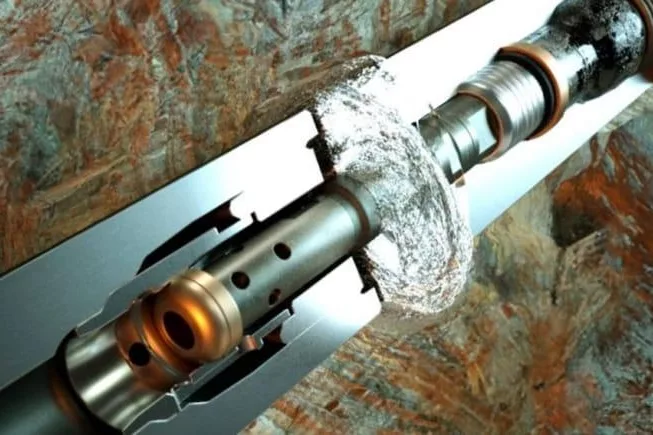

- Expro’s patented HI TOOL™ has been designed to dampen detrimental vibrations. The tool’s elastomeric “Anti-Vibration Rings” and spherical geared connection allows for minute flex / tilt to occur between the axis of the upper body and lower body which helps to dampen and decouple the BHA without having any manipulation towards drilling input energy. As a result, vibration generated by drill bit, underreamer, and bottom hole assembly are minimally transmitted along the string and drill strings dynamics can be improved allowing better drilling performance

- One of the main challenges of this project was the relatively long 2,013m lateral drilling and under reaming section with the Rotary Steerable BHA

- If Expro did not provide a solution there would have been premature damage in drill bit and underreamer cutting structure, potential BHA failure, shorter footage and/or slower drilling penetration rate

Value to Client

- This vibration mitigation allowed for improved drilling efficiency for the customer, giving drilling stabilization

- Drilling assembly can concentrate more of its input energy into penetrating the rock as less energy is lost due to instability, vibration, and negative drilling dynamics

- Expro drilled 2,013m of larger opening ratio from 2,000mMD to 4,013mMD, double the meterage of the offset well, over 93.5hrs drilling hours with good ROP 23.4m/hr. while significantly mitigating stick-slip

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU