Case Study

70% Reduction in Drill-Out Time for North Sea Operator

Product Line

Challenge

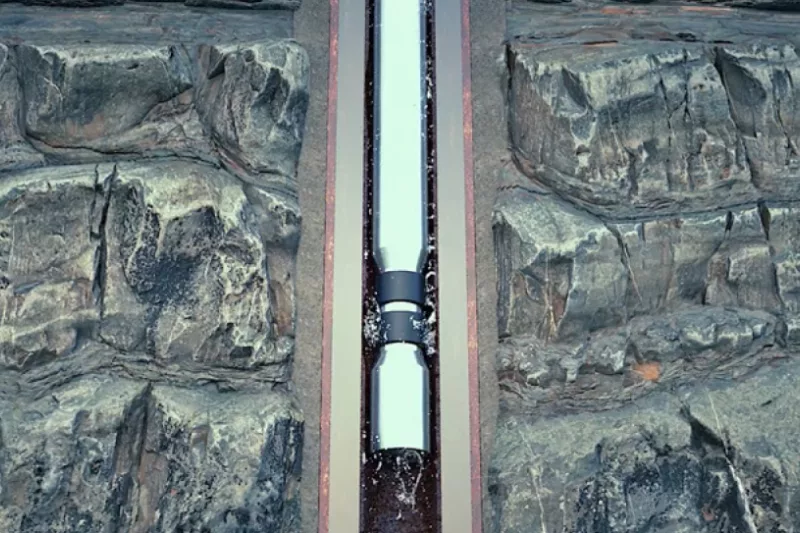

An Operator in the North Sea approached Coretrax as they were experiencing an issue with two unstable zones located below the 10 ¾ 65.7 lb/ft liner shoe. These unstable Shales prevented the ability to drill into the reservoir due to the potential for hole collapse due to the low mud weights required to penetrate the reservoir. The Coretrax ReLine DL drilling liner enabled the Shales to be isolated whilst providing required hole diameter for successful reservoir completion.

Solution and Achievement

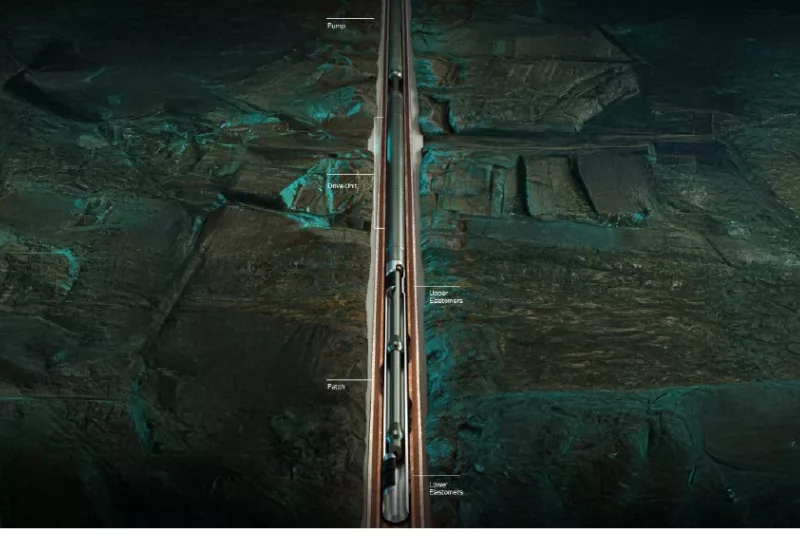

The Operator challenged Coretrax to develop several application specific solutions in conjunction with the request to resolve the unstable Shale issues. These included:

- Develop a system that would be suitable for application across several different assets and base casing weights whilst delivering a custom ID

- Capability for high flow rates to improve circulation

- High Torque ratings (25,000 ft-lbs) to be able to work through challenging sections safely

- Redesign Guide Shoe to minimize drill out time whilst retaining integrity

The project, spanning from April to October 2023, consisted of three well installations. The Coretrax 8 5/8” ReLine DL expandable drilling liner system enabled these problematic zones to be isolated successfully whilst landing the liner in the top of the reservoir thus allowing the wellbore to be subsequently drilled ahead to Total Depth (TD) in 8 ½” diameter with low mud weight.

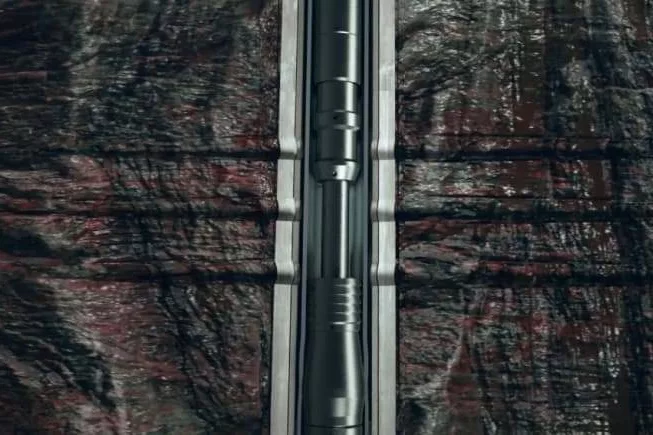

Incorporating the insights gained from the initial well, the second installation showcased advancements in well cleaning techniques. Consequently, 120m liner was seamlessly run and expanded on the first attempt, avoiding any difficulties.

The project's success across other assets has in part been attributed to the proactive approach adopted by both the Operator and Coretrax in addressing challenges and continuously refining technology and procedures.

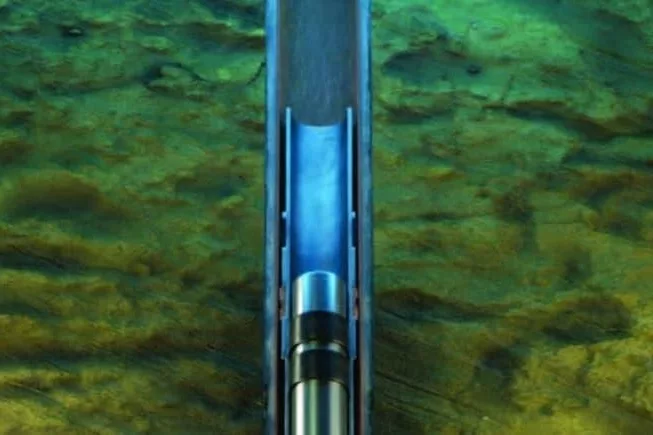

The implementation of the new guide shoe design resulted in substantial time savings. Feedback from the Operator highlighted Coretrax’s responsiveness to challenges and the commitment to technological advancement. As a result of the successful execution, a third ReLine DL system was installed in October 23.

Key Benefits

Coretrax 8 5/8” ReLine DL system successfully isolated unstable Shale formations whilst enabling Operator to drill 8 ½” hole to TD

The development of a new double float shoe design has also contributed to operational efficiency

70% reduction in drill-out time in comparison to the previous design

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU