Case Study

Custom completion screen solution maximizes efficiency and safety for Canadian offshore operator

Contact

In Brief

A supermajor operator in Canada sought to optimize running ISAPT (Internal Shunt Alternative Path Technology) lower completions screens.

Product Line

Region

Customer Challenges

The reduced handling area and weight of the screens posed unique handling challenges for the operator. In previous operations, they were also experiencing a very slow joints per hour run rate with a high rejection rate, which was leading to increased operating costs. The conventional process used for these installations also involved personnel operating in the red zone and derrick, which introduced further safety hazards to the job.

Expro Excellence

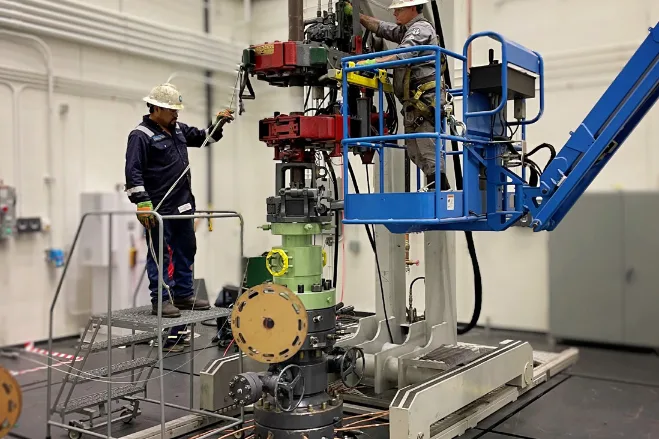

To address these challenges, Frank’s TRS commissioned a customized and unique solution encompassing a combination of our proven proprietary products:

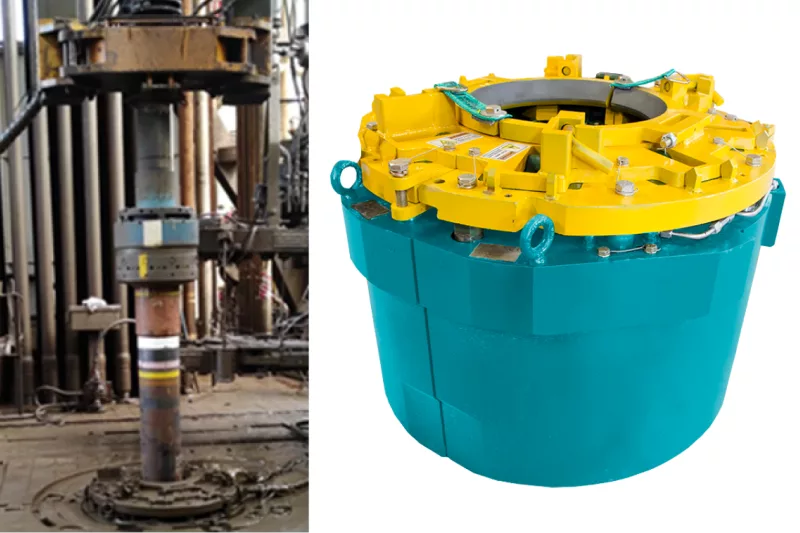

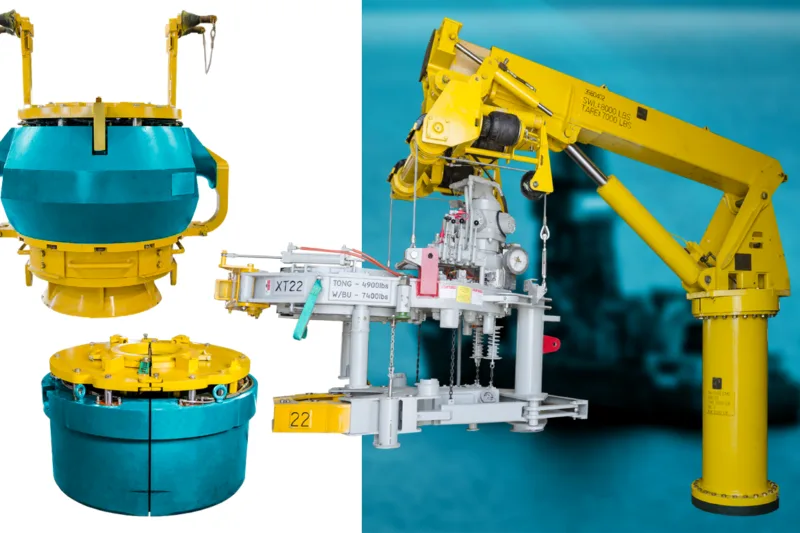

- Collar Load Support System (CLS™), a one-of-a-kind zero-marking spider elevator system with specially designed lifting and handling components for the ISAPT screens’ special handling requirements

- BACKPACKER™ Compensator System, a single joint compensator designed to aid in the running and pulling of premium thread tubulars. The BACKPACKER™ ensured the weight of the screens was being properly supported during operations, preventing unnecessary damage to the connection during the stab in and make up process.

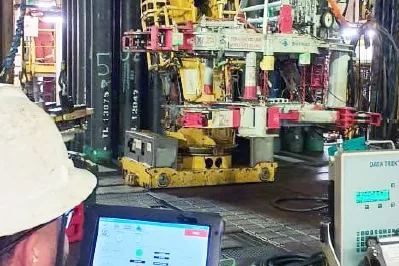

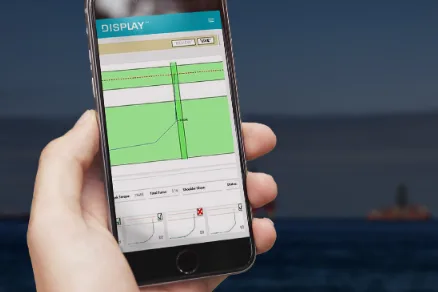

- Remote Tong System (RTS), a specialized system with a mechanized component allowing remote positioning and operation of the tong. Frank’s TRS customized and integrated our standard RTS into the rig equipment, easing the interface while further reducing the need for personnel to enter the red zone and increasing efficiency during the installation of the screens.

Value to Client

Frank’s TRS tailored solution, combined with operational planning and execution, led to several record setting screen runs. The unique CLS™ System led to a significant increase in running efficiency, raising the average joints per hour from three (3) to seven (7) and over the entire 13 well project, Frank’s TRS ran a total of 1,357 joints with our BACKPACKER™ and had only one (1) rejected connection due to make up issues. This performance was a huge improvement over the 20% rejection rate the operator experienced in previous installations. Further, the improved average running speeds and operational efficiencies resulted in a savings of approximately 14 hours per job.

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU