Case Study

Expertise in Well Flow Management solves challenge on major environmental project

Contact

In Brief

Expro’s solution enabled the customer to steadily sequester large volumes of CO2 to minimize the environmental impact of their overall field production

Region

Customer Challenges

- A multinational energy company in Australasia is operating a Carbon Capture and Storage (CCS) project and had encountered injectivity challenges on pressure support wells that were integral to the success of the project

- Fluids were being pumped via an Electro Submersible Pump (ESP) installed in a CO2 storage formation to an adjacent pressure support well in order to regulate the pressure in the storage formation. The fluids contained unexpected fine solids which resulted in a loss of permeability in the pressure support well, limiting the customer’s ability to sequester CO2 into the storage formation

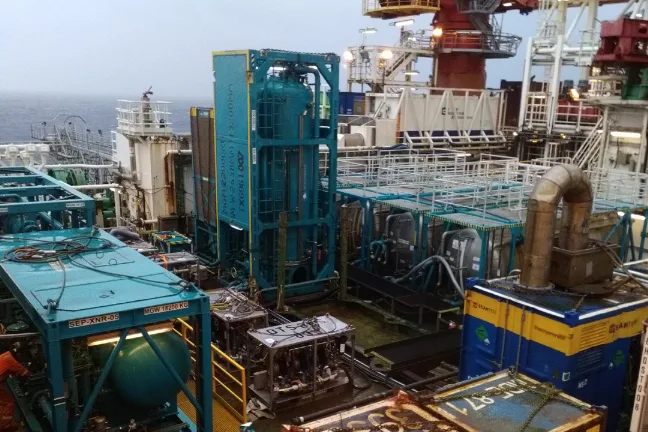

- Design parameters required processing of 40,000 bpd of corrosive water or fluids, at temperatures up to 120°C and pressures up to 1,315psi across two separate sites

- A solution was required for implementation with expedited delivery to support in meeting the customers intended target

Expro Excellence

- Expro’s team of Well Flow Management experts were consulted to provide a bespoke, ultra-fine solids removal solution allowing no particles above 5 microns in size to pass (for comparison: human red blood cells are ~7um), whilst minimizing pressure loss across the system;

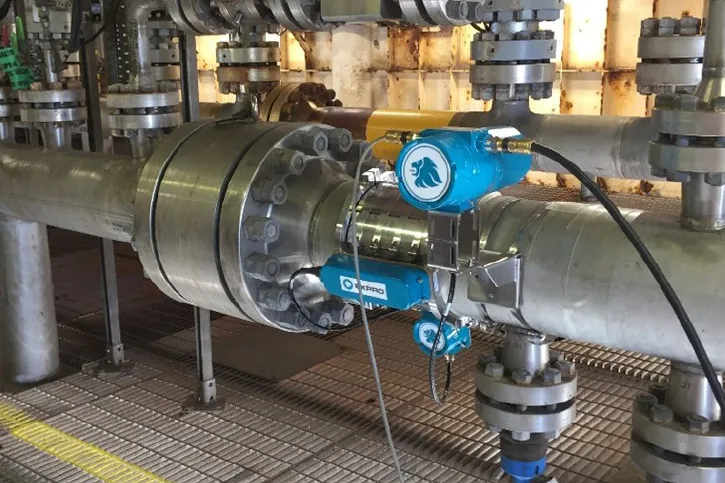

- Expro selected each package with two stages of solids filtration:

- Stage 1 consists of x2 hydrocyclones in parallel, removing solids down to 10 microns in size; each rated to 100% flowrate capacity, yet configured with differing range efficiencies - to maximize separation efficiency across the entire range of flowrates during production

- Stage 2 consists of x2 filtration units in parallel allowing pass-through of particles 5 microns in size (absolute). Configured in a duty/standby arrangement, each are rated to 100% flowrate capacity

- Additional ultra-fine hydrocyclone units capable of removing in-line solids further down to 3 microns were also deployed to the project as contingency for even finer solids removal; or to maximize the lifespan of second-stage filter elements

- Expro’s ultra-fine solids-removal systems allowed our customer to achieve their objectives with an immediate increase in the injection rate of the fluids into the pressure support well

Value to Client

- Expro’s solution enabled the customer to steadily sequester large volumes of CO2 to minimize the environmental impact of their overall field production

- These packages also provide the customer with opportunity to gather valuable reservoir/production data which can be utilized to optimize the design of the overall CCS project plan

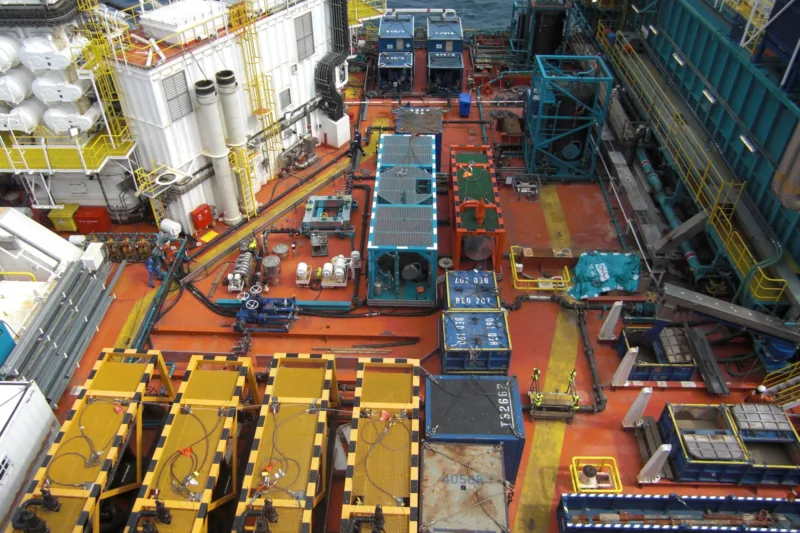

- Within six months of being approached with the challenge; Expro had designed, constructed and mobilized the first solids-removal package to the job site, commencing operations in March 2021. The second package was operational only two months late

- This project has been operated and maintained with the ethos of “keeping it safe” which has translated to:

- Zero HSE incidents

- Zero hours of Non-Productive Time (NPT) and minimal downtime to the customer

- Over 40,000 man hours spent on the project to date, allowing for maximum utilization of the CCS facilities

- Expro is proud to be applying its 50 years of Well Flow Management expertise onto many new global initiatives to protect our environment: enabling CO2 sequestration in conventional energy production, and also supporting development of new alternative energy sources for the future. CCS is critical to a lower carbon future and essential to achieving the net zero goals of the Paris Agreement

Contact

For further information, please contact WFM@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU