Case Study

Isolating Casing Leaks and Meeting CAlGEM Integrity Requirements

Product Line

Region

Challenge

In July 2023, a leading oil and gas operator faced a critical challenge in isolating casing leaks within their well infrastructure. These leaks not only posed a threat to operational efficiency but also threatened compliance with the integrity requirements set forth by the California Geologic Energy Management Division (CalGEM). Previous attempts at resolving the issue through traditional cement squeeze methods had failed, leaving the operator in a difficult position.

Solution and Achievement

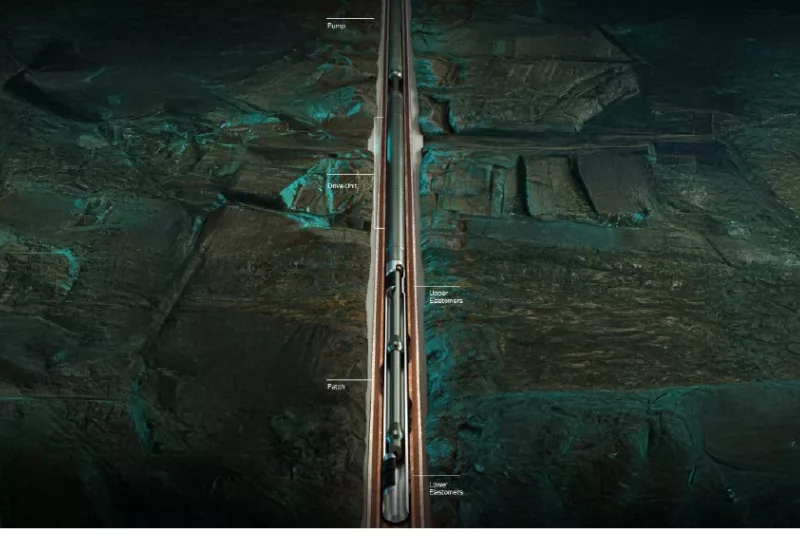

To address the persistent casing leaks and regain injection capability, the operator turned to an innovative solution—ReLine MNS. This advanced technology offered an alternative to the ineffective cement squeeze methods. The operator recognized that a new approach was necessary to meet the CalGEM integrity requirements and ensure long-term operational safety.

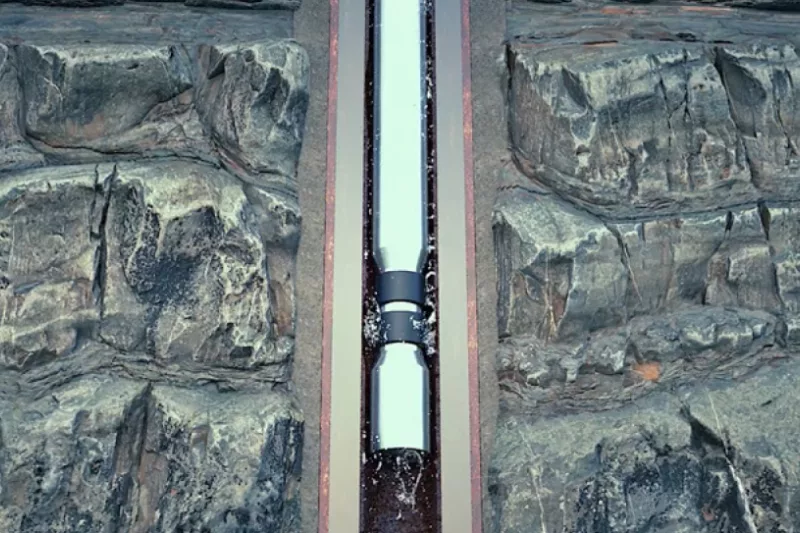

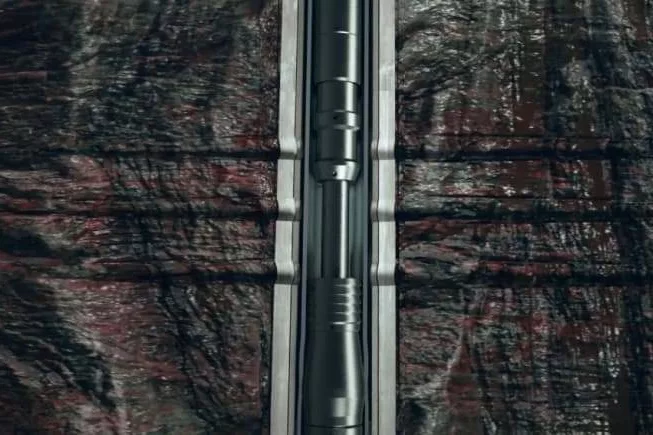

The ReLine MNS technology was selected to replace the series of failed cement squeezes. This decision was driven by the technology's proven track record in effectively addressing casing leaks and its potential to meet CalGEM's criteria. The chosen approach involved installing an approximately 800-foot liner.

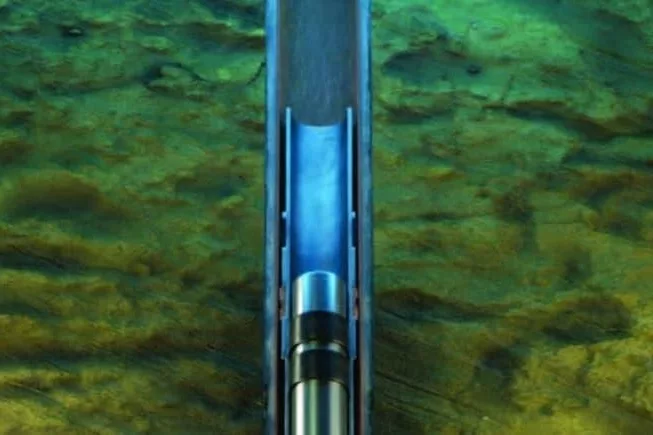

The liner was successfully and safely installed in the well infrastructure and the isolated casing leak underwent a rigorous pressure test, witnessing pressures of up to 500 PSI over a duration of 30 minutes. This pressure test was a crucial step in ensuring the integrity of the solution and compliance with CalGEM requirements.

Given the uncertainty associated with the life expectancy of a cement squeeze and potential costs of subsequent squeezing, the operator realized the cost savings of utilizing an expandable casing patch as a permanent remediation solution that will last the life of the well.

Key Benefits

The operator's decision to implement the ReLine MNS technology yielded impressive results. By successfully isolating the casing leak and undergoing the demanding pressure test, the operator achieved a significant milestone in well integrity restoration. The technology's performance not only met but exceeded the strict compliance standards set by CalGEM, showcasing its effectiveness in critical situations.

The achievement was met with approval from the Operator, who expressed high levels of satisfaction with the installation. The ReLine MNS technology demonstrated its capability to perform as designed and emerged as a viable alternative to the conventional cement squeeze attempts that had previously failed. The successful implementation of this innovative solution not only addressed the immediate challenge at hand but also presented a sustainable option for future well integrity restoration projects.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU