Case Study

Reline MNS Restores Well Integrity by Addressing Casing Corrosion

Product Line

Region

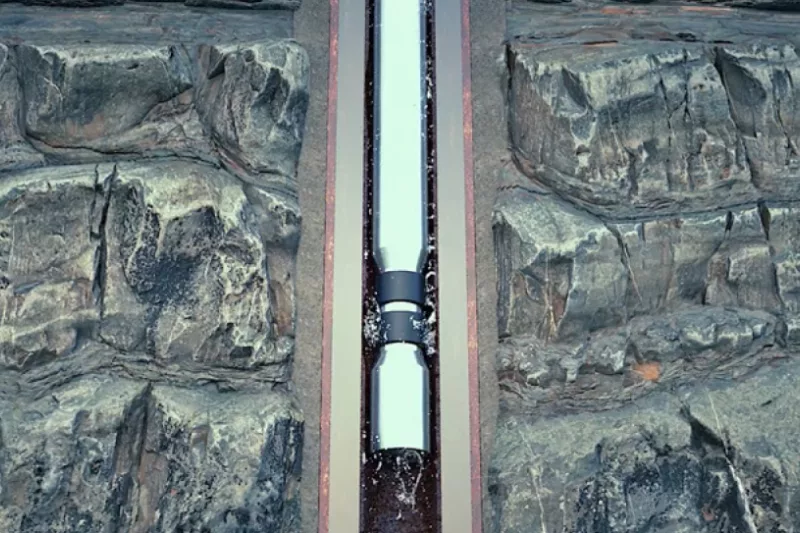

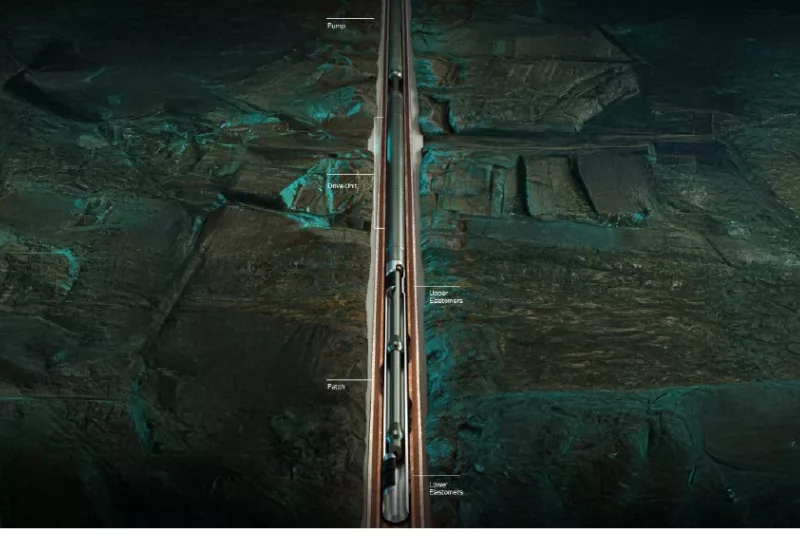

After reviewing corrosion logs of this vertical injection well, a significant anomaly was observed indicating up to 57% metal loss at 7,005 ft across a 4-1/2” 11.6# liner. In anticipation of further corrosion, it was necessary to isolate this section of casing.

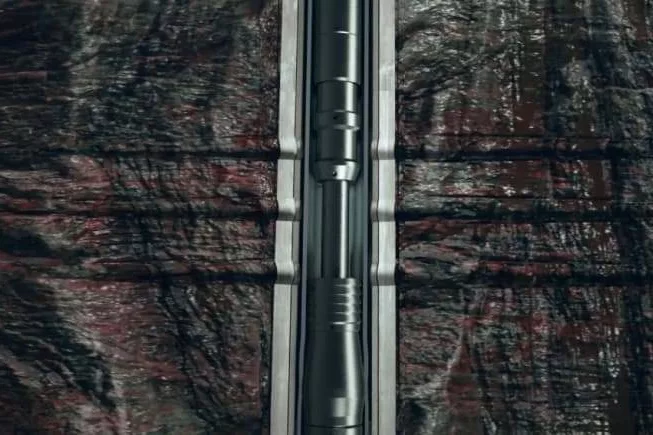

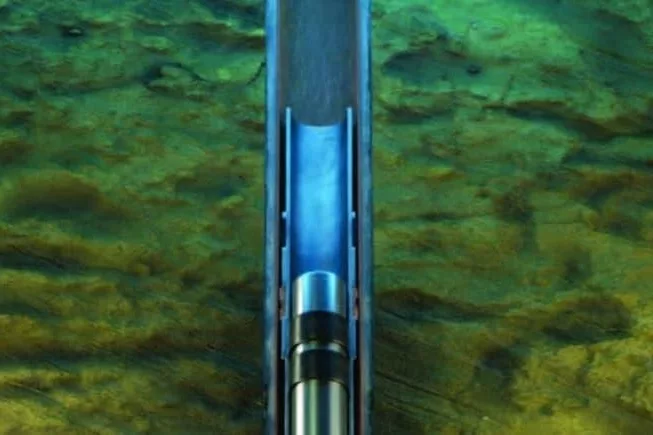

Coretrax’s ReLine MNS cased hole patch system was selected to cover and mechanically isolate the corroded interval. With premium expandable connections and a 10,000psi rating, the patch length was calculated to provide optimum coverage of the compromised casing section.

The 300ft long patch was deployed in a single trip with no shoe to drill out after installation. NACE tested and H2S resistant, the patch successfully mechanically isolated the problem area allowing for well integrity to be restored. Once installed the patch was expanded to provide an ID of 3.4.16”, ensuring maximum ID for future well operations.

Key Benefits

Well life extended by effectively addressing well corrosion

Deployed in single trip

No shoe to drill out

10,000psi rated

Minimal restriction created for future well operations

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU