Case Study

Shallow Set 13 3/8” Expandable Casing Patch and Retrievable Test Packer Allows Drilling Operations to Continue in the Central North Sea

Product Line

Problem

A North Sea platform had identified external corrosion wear in the 13 3/8" 54.5# casing at 151 ft which was also the sea level depth from RKB. The plan prior to identifying this corrosion was to drill an 11" sidetrack below the 13 3/8" shoe.

Solution and Achievement

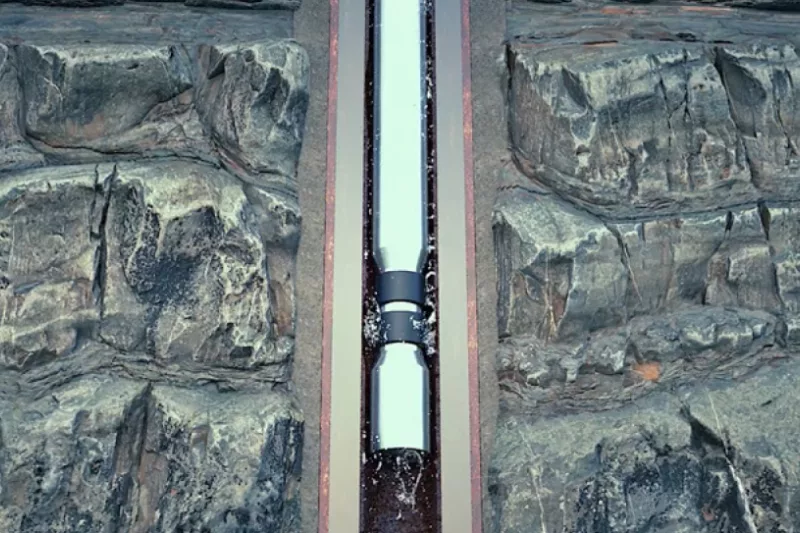

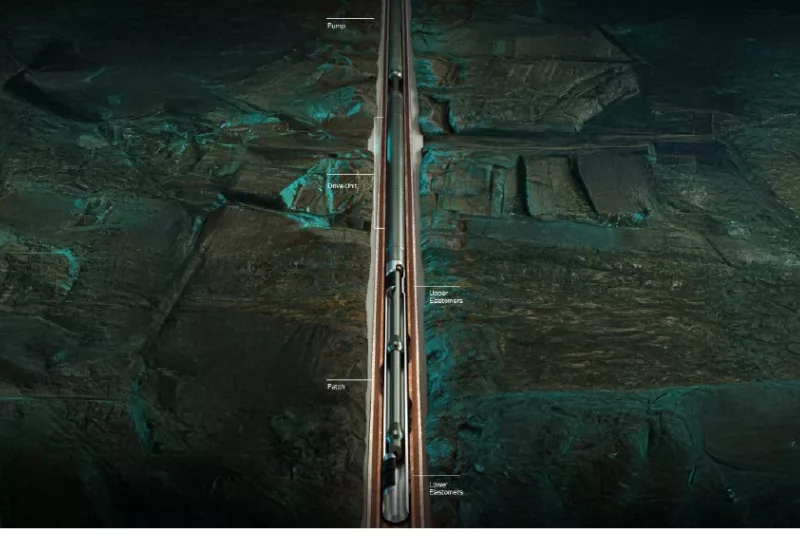

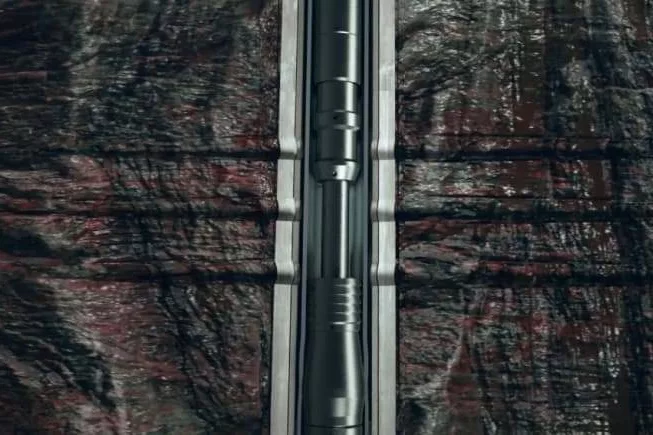

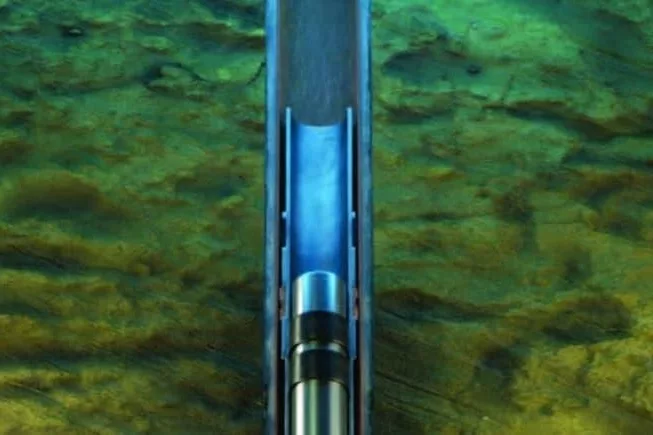

To pinpoint the leak in the 13 3/8” casing, a Coretrax CXRTP (Retrievable Test Packer) was set and pressure tested over five separate depths between 100ft and 164ft. With the leak depth now identified, the two onboard Coretrax expandable casing and liner engineers ran a 148ft Coretrax CORE HYD 10 ¾” OD patch system which was set from 251ft up to 103ft with a five stack HNBR seal assembly above and below the leak point to completely isolate this issue.

The HYD system uses hydraulic pressure to push the expansion cone up through the expandable casing usually until it exits, however, due to the shallow depths and the fact that the top of the expanded casing was dry, casing jacks were used on the rig floor to safely expand the final 9ft to avoid a final sudden shallow release of pressure as the expansion cone exits the top of the system. This was done with great success.

With the patch set and tested, a large post expansion ID of 11.798” allowed the sidetrack operations to be carried out.

The operator was happy with the efficiency and being able to continue drilling operations.

Key Benefits

This short patch was enough to get the well back on track to be sidetracked and later produced, potentially saving a entire casing string replacement.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU