Case Study

Coretrax Expandable Drilling Liner Aids Drilling Efficiencies to Get Unconventional Well Back on Track in Midland, Texas

Product Line

Region

Challenge

Whilst drilling through the curve in an unconventional well in Midland, Texas, USA, the operator was unable to achieve sufficient mud column height to enable drilling operations to continue. An approximate 1,200ft (366m) long solution was required to maximize well bore ID and continue normal drilling operations.

Solution and Achievement

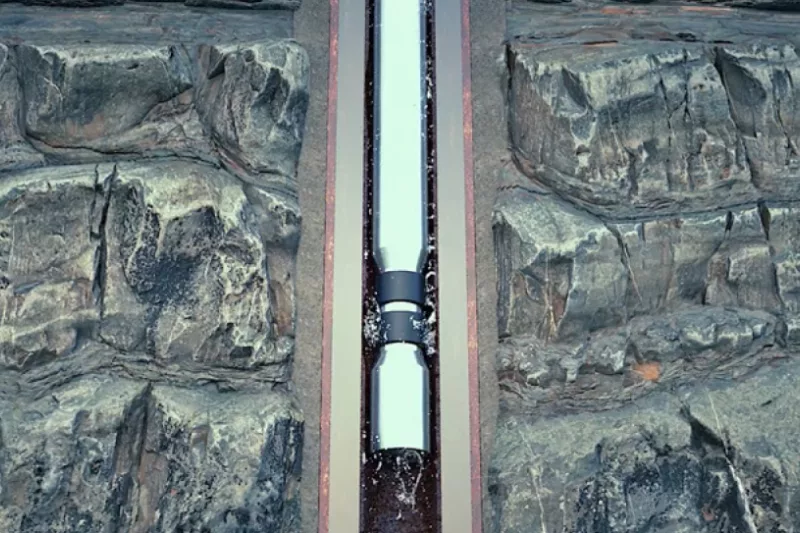

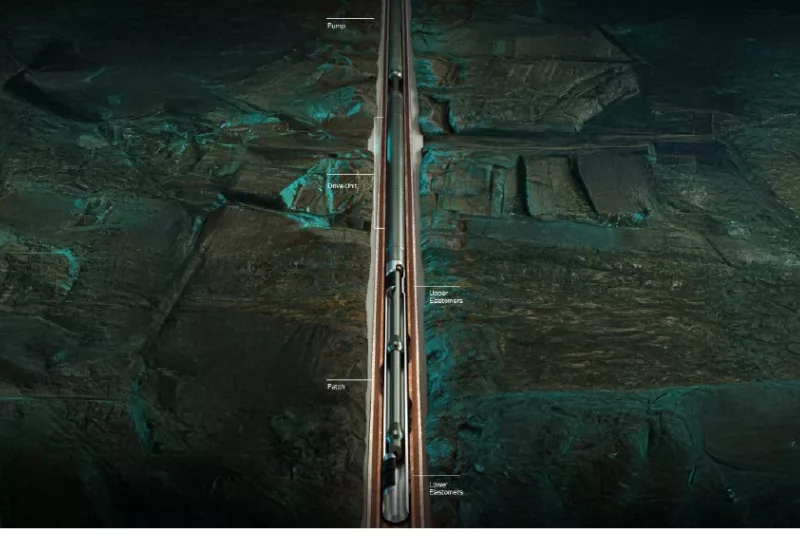

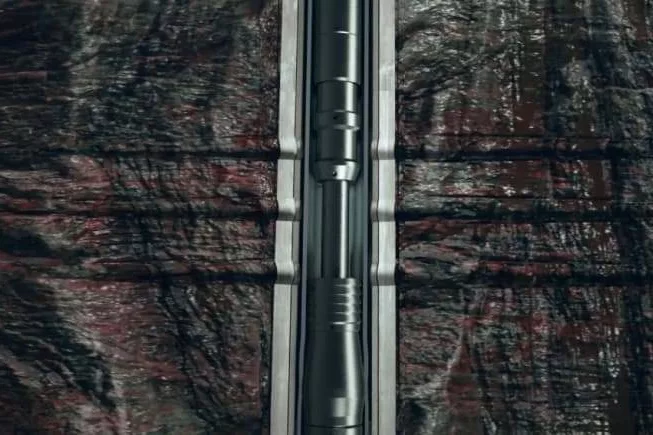

Coretrax Global were called to run a 7 5/8” x 9 5/8” 40# Expandable Drilling Liner (Coretrax DL) outside the 9 5/8” shoe to stabilize the hole and isolate the problematic zone to allow drilling operations to continue.

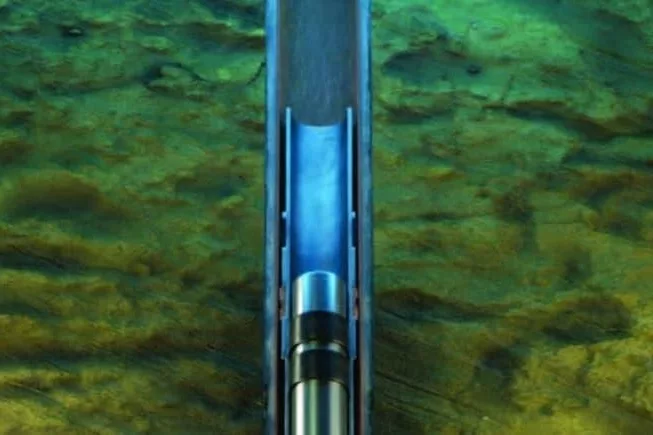

Upon successful running and testing of the expandable system, the operator was able to regain the capability to run their desired liner size out into the horizontal open hole section.

Note: With premium expandable connections, up to 4,000ft of Coretrax Drilling liner can be run and expanded.

The continuous 1,146 ft expandable liner was successfully deployed and tested from 9,399ft to 10,545ft, and whilst running the drilling liner, the cement was properly displaced and a cement dart seated in shoe. The Coretrax drilling liner was then successfully expanded to achieve an ID of 7.967” and the running tools pulled out of the hole.

Key Benefits

Coretrax gave the operator the ability to avoid having to displace the well to an expensive drilling fluid or a sidetrack / re-drill.

The system was delivered, run, and tested in a matter of days to get the well back on track.

The incorporated aluminum shoe allows the liner to be positive tested before drilling ahead.

As the Coretrax drilling liner is an expandable system, a much larger ID is obtained compared to a conventional liner system.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU