Case Study

Coretrax Expandable Drilling Liner Allows Permian Well Drilling to Continue

Product Line

Region

Challenge

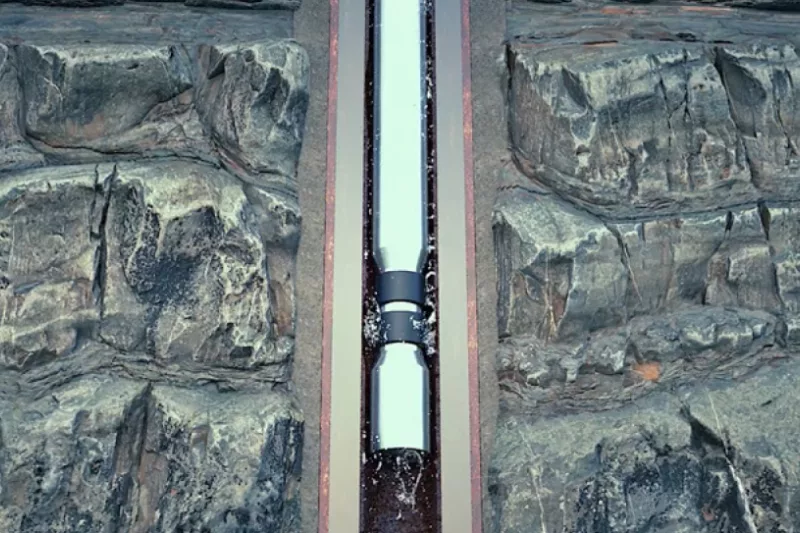

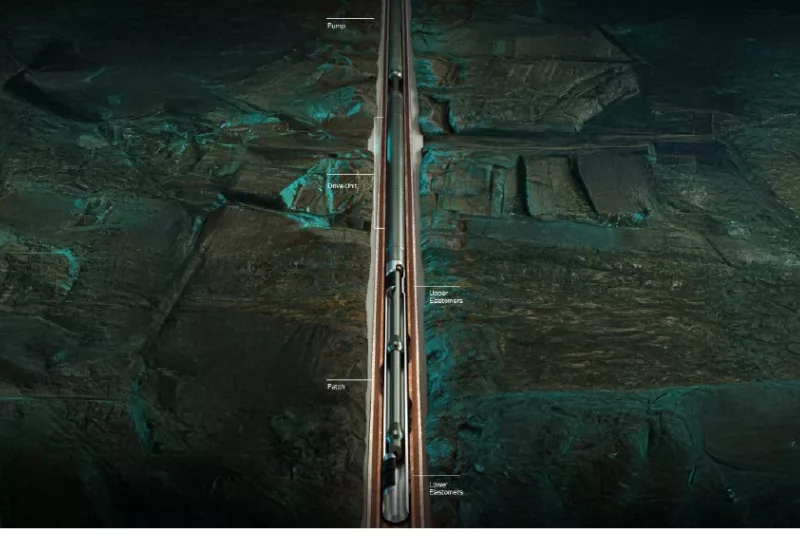

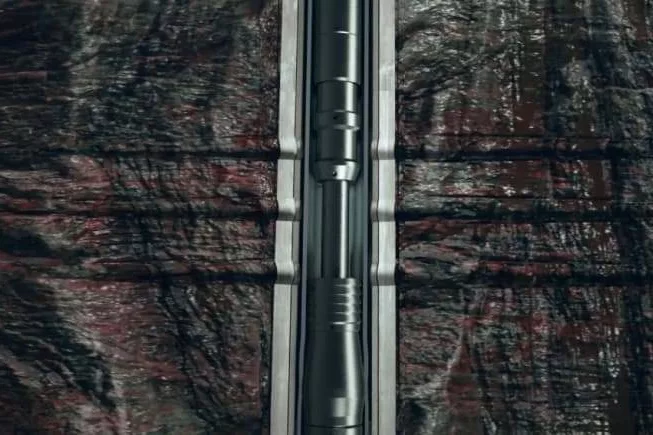

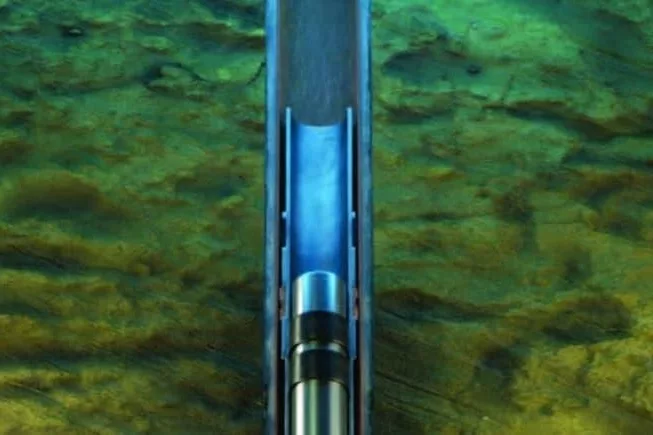

A West Texas operator needed to isolate a section of casing in the intermediate 9-5/8” 40# string due to a parted joint that was found only after the casing had been cemented in place. The patch allocated for the application was a 7.625” x 9.625“ Re-Line DL which is ideal for cased-hole and cased / open hole applications and once set and expanded, provided a 7.908” post expanded ID allowing operator to utilize a preferred 7-7/8” drilling BHA, to drill ahead.

Solution and Achievement

The short two joint patch was RIH, set and pressure tested successfully at 5,502ft

With the running tools out of the hole, the incorporated aluminum shoe within the base of the patch was drilled out in less than 20mins, leaving the operator able to continue operations with the preferred drilling BHA size of 7 7/8”.

The operator was extremely pleased with not only the patch, install and drill out time, but with the quick turnaround too.

Key Benefits

Coretrax gave the operator the ability to avoid a side track / redrill.

The system was delivered, run, and tested in a matter of days to get the well back on track.

The incorporated aluminum shoe allows the liner to be positive tested before drilling ahead and was drilled out in a very short time.

As the Coretrax drilling liner is an expandable system, a much larger ID is obtained compared to a conventional liner system which allowed the operator to utilize the preferred 7 7/8” drilling

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU