Case Study

Coretrax Used Re-Line MNS to Isolate 2,300 ft of Corroded Casing in a West Texas Well

Product Line

Region

Challenge

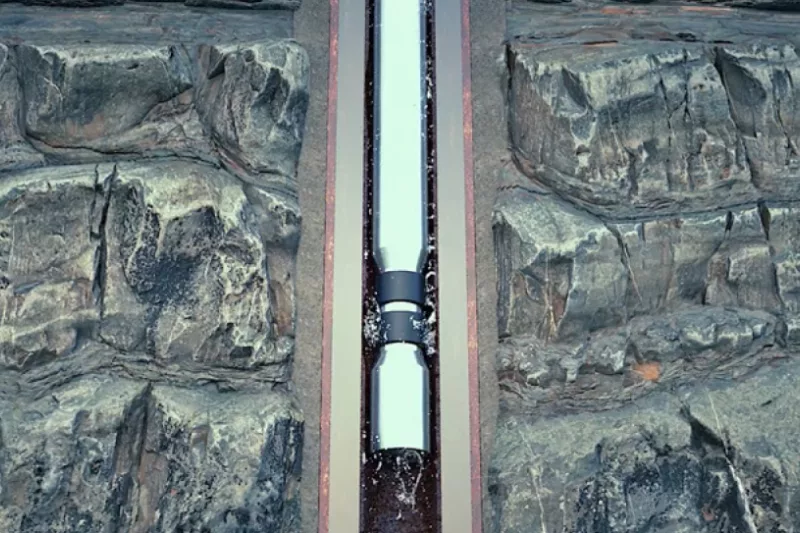

A West Texas operator needed to isolate over 2,300ft corroded casing due to water flow in their West Texas well. Multiple attempts to squeeze cement had failed and the customer needed a permanent means to isolate this problematic corroded casing section.

Solution and Achievement

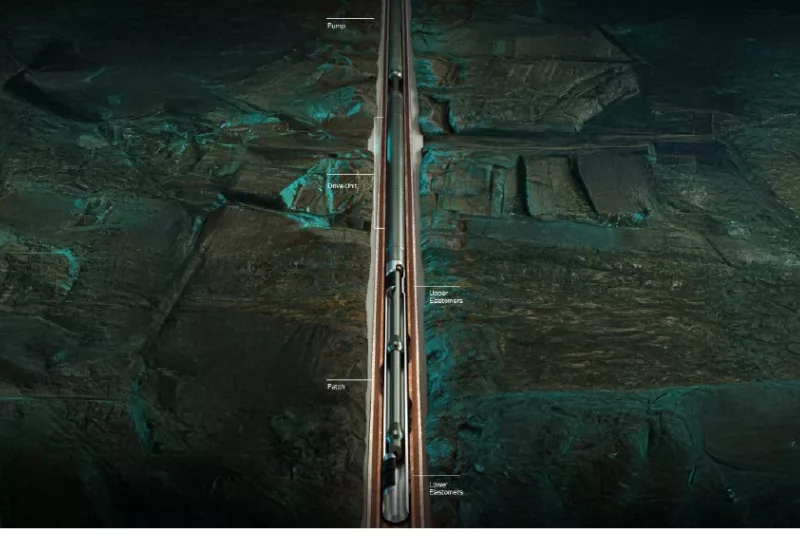

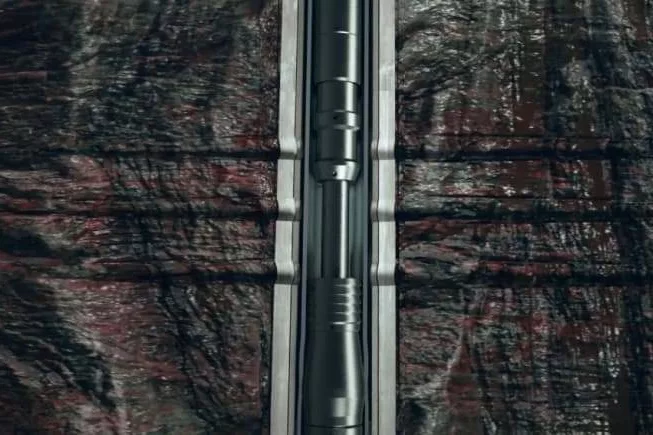

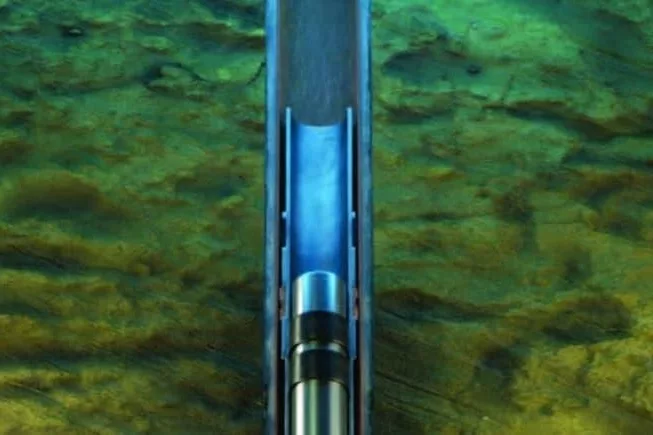

A Re-Line MNS 4.25” x 5.5” 17# system was chosen as it features no shoe drill-out (MNS = Mechanical No Shoe) and its larger post expanded ID which allowed a specific sized large OD ESP to be run afterwards.

Prior to running the Re-Line MNS, Coretrax were able to provide the full well bore clean out using the Coretrax ORIGIN mechanical clean out and debris recovery tools, whilst at the same time drifting the casing to ensure the path ahead was clear before running the patch.

Having the Well Bore Clean Up / diagnostic run, performed by the same company that runs the patch not only saves time and trucking, but also means less personnel are sent to the rig.

The Re-line MNS patch was run and tested with no issues at all, and the customer was delighted to have the well back on track so quickly and efficiently.

Key Benefits

Coretrax were able to clean out the well with tools and personnel from the same load out.

The system was run and tested with no issues to completely isolate the corroded casing.

The MNS system means that once the patch is set and tested, there is no shoe to mill out, so the next operation can go ahead immediately.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU