Case Study

Reline DL System Isolates High Pressure Formation

Product Line

Our client in Albania had a planned sidetrack well that required a solution to isolate a high-pressure formation, just outside the milled window, from lower pressure zone below, to enable the drilling and stimulation of this reservoir section.

Project Details

Location : Albania

Rig details: Land

Parent casing: 7” 35 lb-ft and 7”42.7 lb-ft run through.

Window information

Top of Window: 3,207m

Bottom of Window: 3,211m

Open hole: 5.625” opened up to 6.500”

Drilling fluid type: WBM Salt/Gypsum

Mud weight: 1.54/1.59 gr/cm3

Solution

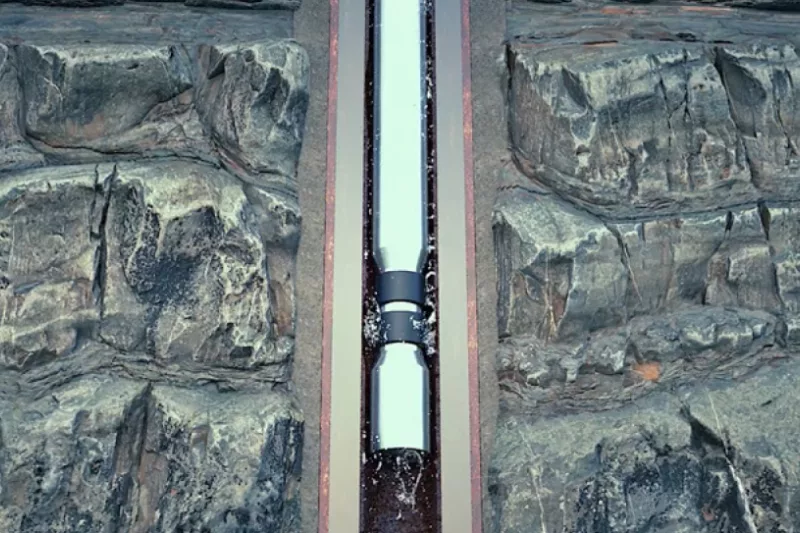

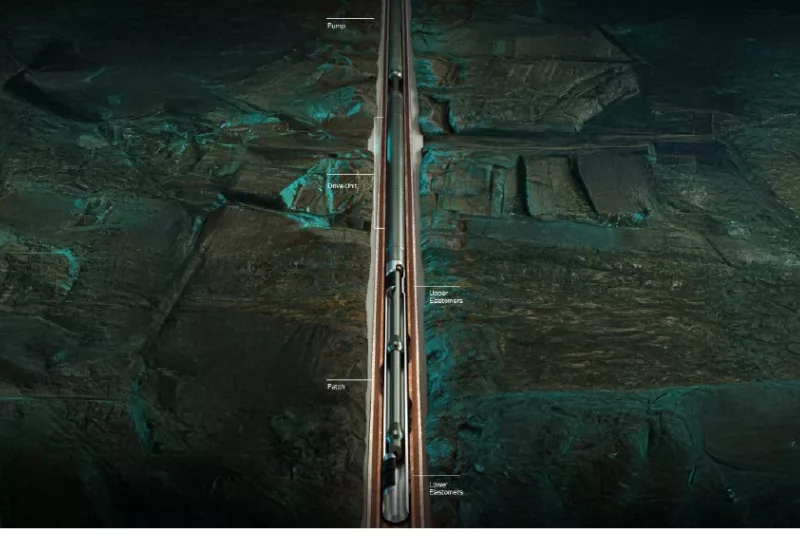

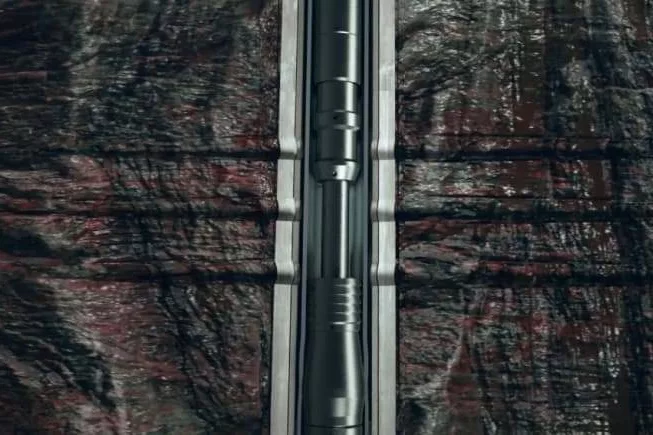

Well parameters were analysed and our 7”, 35 lb/ft ReLine DL - Expandable LinerReLine DL expandable open-hole liner system was selected as the optimal solution. The ReLine DL selected will be installed into a 6-1/2” under-reamed open-hole section from 3,184m to 3,304m MD.

Due to a section of 42.7# casing within existing architecture, custom seals were developed to enable passage through this restriction.

Achievement

Our 7” 35 lb/ft ReLine DL was deployed through a milled window within the 7”casing. A primary cement job was conducted prior to the successful expansion into a 6-1/2” underreamed open-hole section from 3,212m to 3,285m MD to isolate the high-pressure formation.

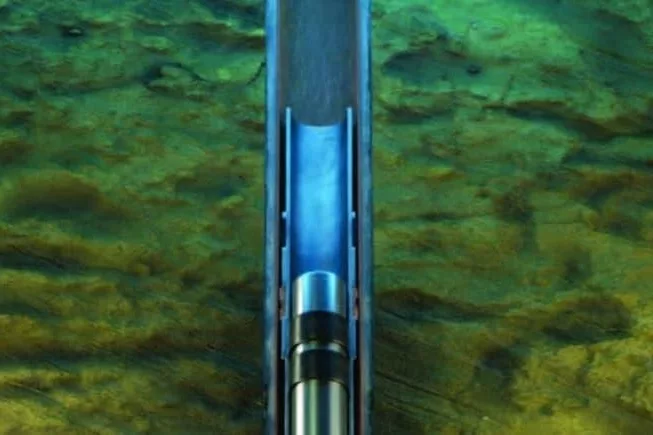

With the HP formation fully isolated, and the ReLine DL sealed and tied back into 7”35# casing, our post expansion ID of 5.140” allowed the operator to drill ahead to a 4 ¾” reservoir section, install preferred 3 ½ liner for stimulation and production of natural gas.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU