Case Study

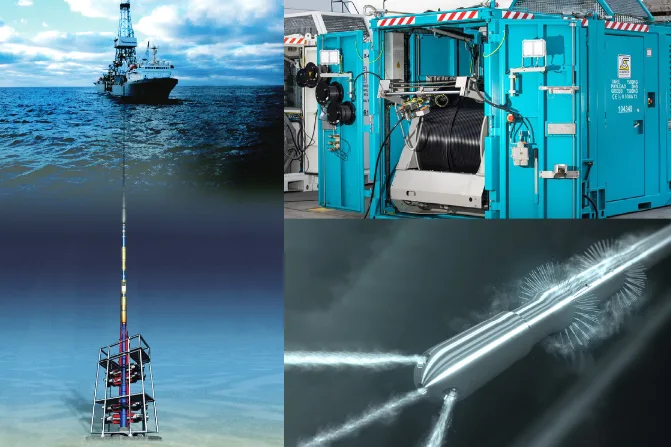

Restoring downhole safety valve integrity using CoilHose high-pressure water jetting

Contact

In Brief

Expro's CoilHose high-pressure water jetting restores the functionality of the downhole safety valve

Product Line

Region

Customer Challenges

- Customer experienced multiple failures of their tubing retrievable downhole safety valves due to scale build up

- This recurring issue has its challenges, the wells must be periodically cleaned to remove the scale build up within the flow tube and flapper area. Previous coil tubing and mechanical interventions have involved the use of HCL acid

- Ensuring well integrity and consistent production are critical priorities, as such, routine maintenance of tubing retrievable safety valves is essential to ensure the customer maintains wellbore integrity and continues to meet production targets

Expro Excellence

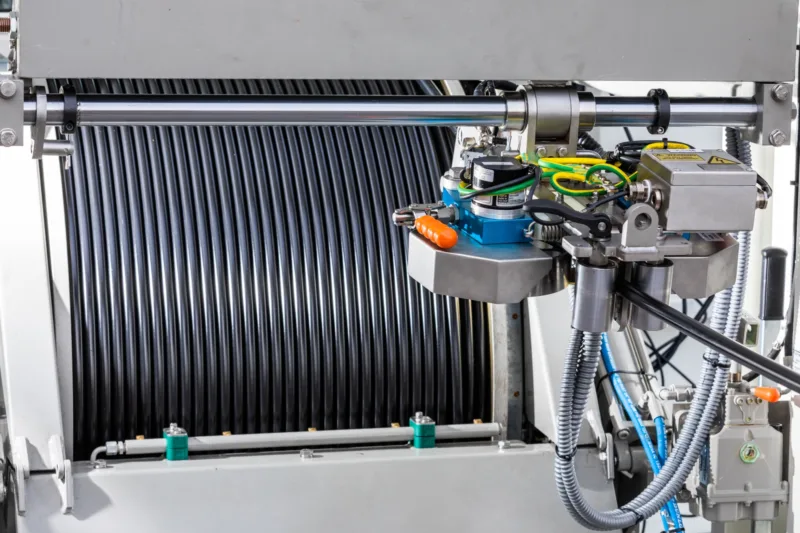

- CoilHose™ was deployed as a compact, high-pressure jetting solution with a customized jetting assembly tailored to the tubing retrievable safety valve internal geometry

- The intervention precisely targeted the scale within the flow tube and flapper area, restoring valve function using only water

- Delivered by a multi-discipline crew within a modular deployment setup, operations were proven to be effective, safe and efficient

Value to Client

- Eliminated need for acid, reducing operational cost, logistic challenges, HSE exposure and environmental impact

- Reduced downtime, restoring DHSV functionality and supporting production continuity

- Reinforced the operator’s long-term maintenance strategy with a scalable, low-risk and chemical free hydraulic intervention option

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU