Case Study

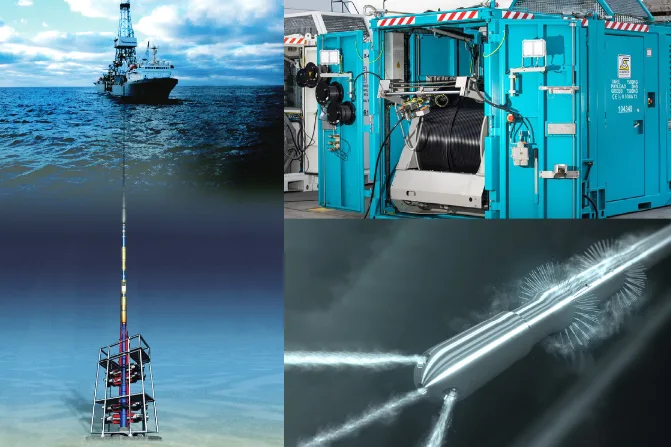

Precision injection: How Distributed Fiber Optic Sensing (DFOS) revealed flow dynamics

In Brief

Distributed Fiber Optic Sensing (DFOS) enabled precise injection monitoring and revealed detailed flow dynamics

Product Line

Customer Challenges

- The customer faced uncertainty in water injection distribution and suspected behind-casing crossflow within a geothermal well

- Temperature and acoustic data indicated potential well integrity issues and inefficient injection performance, particularly in identifying how water was being distributed

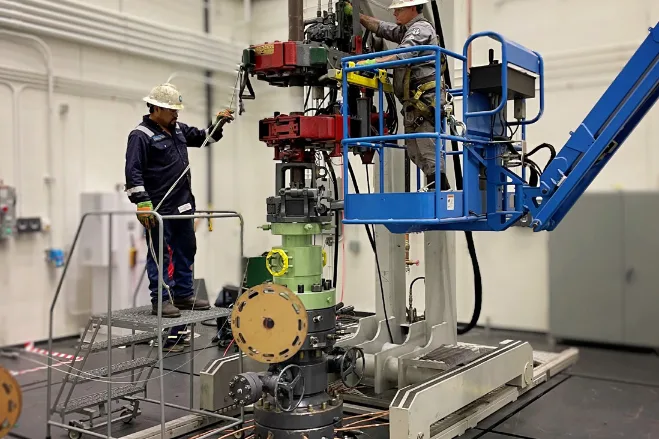

- The well demonstrated exceptionally high injectivity, with injection rates during the survey exceeding -200 m3/h which were significantly above standard PLT specifications

- Expro was selected based on our proven data quality, reliability, and expertise in injection diagnostics

Expro Excellence

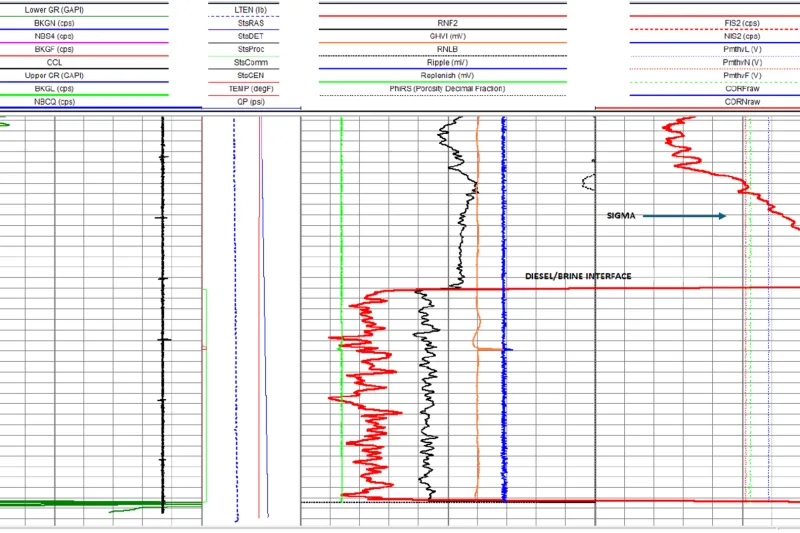

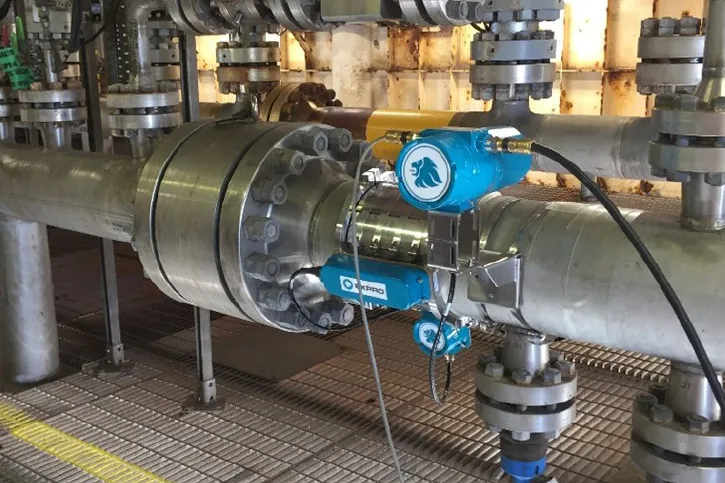

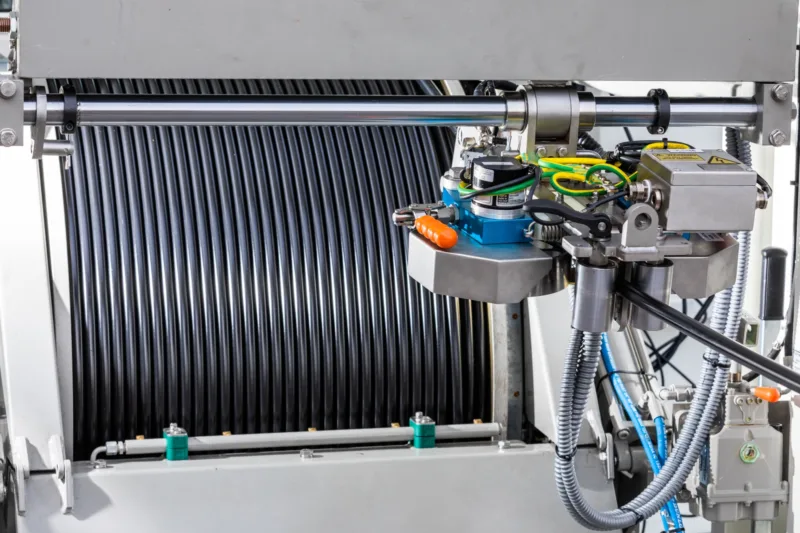

- Expro deployed its Distributed Fiber Optic Sensing (DFOS) solution to perform Distributed Temperature Sensing (DTS) and Distributed Acoustic Sensing (DAS) data surveys under multiple conditions baseline, cold and hot water injection, and shut-in periods to analyze flow dynamics, temperature anomalies, and acoustic signals across the wellbore from surface to HUD

- The DFOS data enabled detailed interpretation of injection distribution, crossflow behavior and reservoir activity

- Qualitative rate measurements were validated to be within -3% accuracy

- The DFOS system demonstrated outstanding repeatability and strong correlation with conventional logs, providing enhanced confidence in the results

- Analysis revealed complex flow behavior characterized by upward crossflow and uneven injectivity across zones. DFOS also identified a localized cooling anomaly, consistent with minimal behind casing communication

- Low injectivity in lower zones with minimal temperature change and acoustic response

Value to Client

- The DFOS survey identified active upward crossflow between injection zones during shut-in conditions revealing pressure differences between reservoirs. The survey provided quantified injection distribution with high accuracy confirming that over 90% of injected water was accepted by the upper zone. The lower zone showed minimal injectivity, and DFOS confirmed minor behind-casing communication

- Understanding the actual reservoir conditions and injection distribution between zones is essential for geothermal project optimization. The data supported robust reservoir modelling and enhanced understanding of injection cycles between zones

- The DFOS survey was completed within one run, capturing where DAS and DTS data under baseline, cold water and hot water injection, and shut-in conditions. This provided real-time velocity and temperature mapping across the wellbore which revealed insights for injector optimization, well integrity assurance and reservoir management

- The survey demonstrated the value of continuous downhole monitoring by enabling early detection of crossflow and improving operational efficiency. It helped the client reduce integrity risks, enhance diagnostic accuracy, and establish a reliable baseline for future monitoring and performance tracking

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU