Case Study

Expro evaluates an overbalance well in dynamic conditions using Production Logging Tools & Jet Pump

Contact

In Brief

Expro's eXPLT workflow delivers large efficiencies in overbalanced wells production optimization in Argentina

Product Line

Region

Customer Challenges

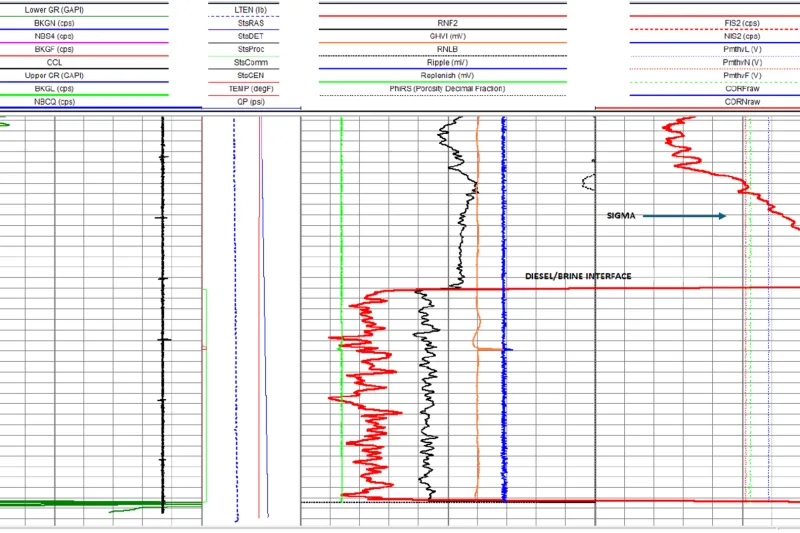

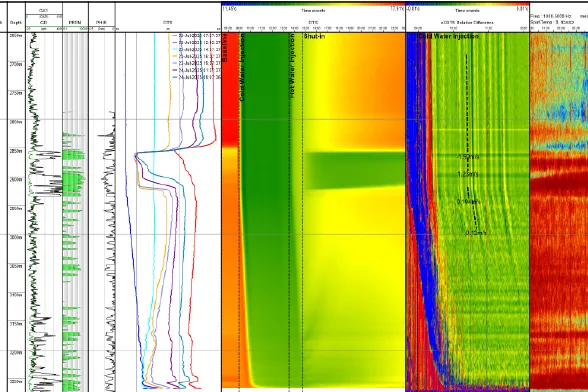

- Our client in Argentina needed to accurately identify the main water-producing zones in a well located in a mature field characterized by extremely high water cut, typically exceeding 90%, to design and execute an effective water shut-off campaign

- High water production was significantly increasing operating costs due to water handling and disposal • Prior to Expro’s involvement, the customer relied on an alternative production logging technology (Target Logging) to acquire PLT data. These operations were time-consuming, complex, and presented elevated safety risks to both personnel and wireline equipment

- The customer required a safer, more efficient, simpler, quicker, and flexible solution that would reduce operational time and complexity while enabling reliable downhole production measurements under challenging well conditions

Expro Excellence

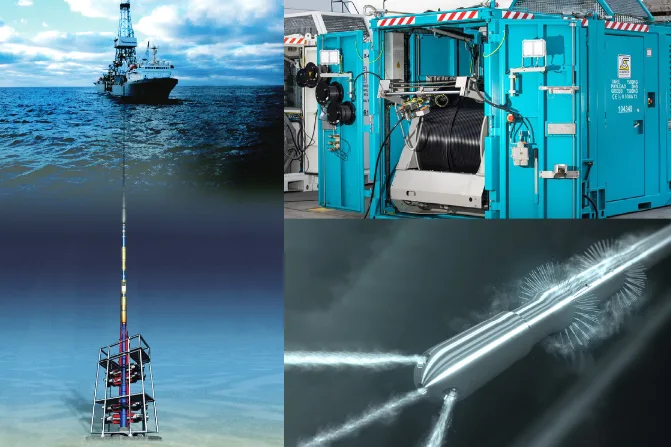

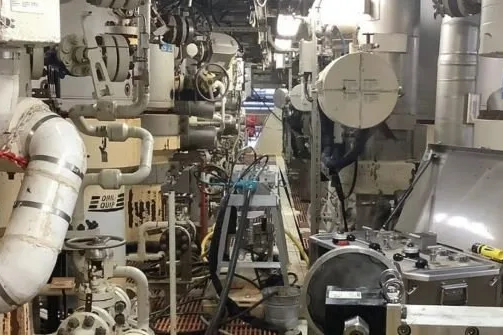

- Most wells were completed with 5.5 in casing, which eliminated the use of conventional Y-tool configurations. At the time, only one competitor in the country could run production logging tools (PLTs) under these conditions

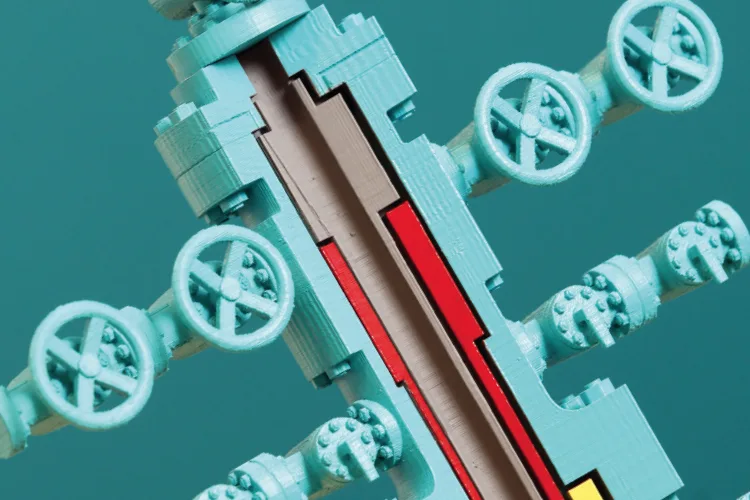

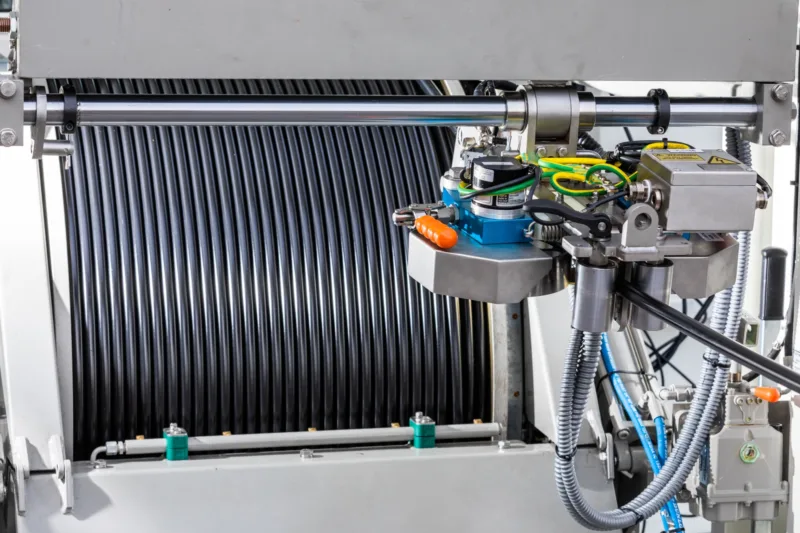

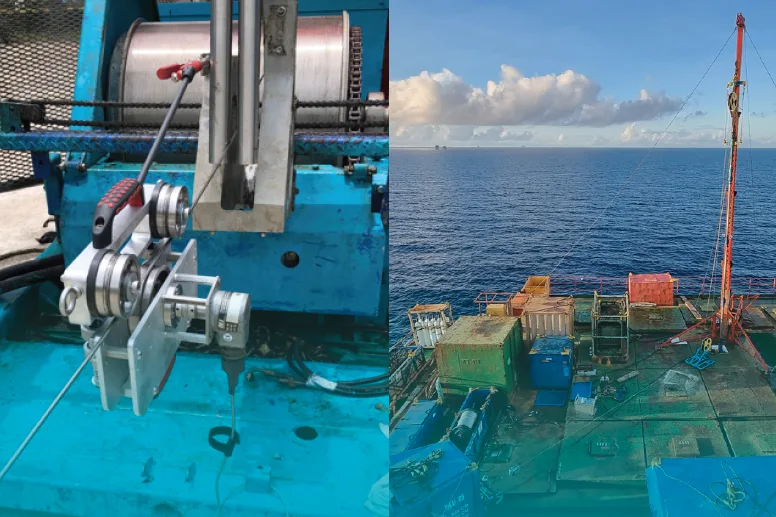

- Expro delivered an alternative solution by integrating wireline production logging with a specially engineered jet pump system that is deployed with simple plain tubing/ completion

- Unlike an Electrical Submersible Pump (ESP), the jet pump operates using injected power fluid, eliminating the need to deploy electrical lines downhole. Filtered produced formation water was used as the power fluid, enabling a more efficient and simplified operation

- As a result, Expro displaced the incumbent service provider and became the customer's preferred supplier

Value to Client

- By providing this solution, Expro enabled the customer to replace a complex and higher risk legacy technology with a safer, more efficient approach

- The operation significantly reduced rig time, improved safety performance, and delivered reliable production data for critical decision-making

- Beyond production logging, this solution also offers flexibility to integrate additional diagnostics such as noise logging and fibre optics broadening well surveillance options and insights

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU