Case Study

Expro well intervention enables geothermal well production to be optimized

Contact

In Brief

Expro helps improve production from single well by 200%

Product Line

Region

Customer Challenges

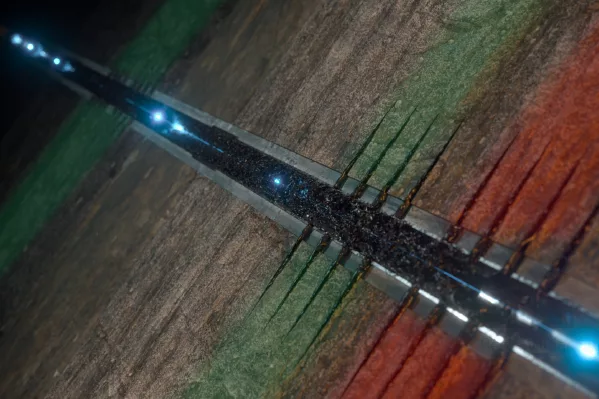

- A customer was having issues with decreased performance on a major geothermal producer in their steam field

- The well originally produced over 12 tons of steam per hour when first brought online. Two years later a production test indicated production had dropped to 3 tons of steam per hour

- The customer subsequently wanted to run a production logging survey for production profiling, but was held up at 2,600 ft due to scale build up in the wellbore

Expro Excellence

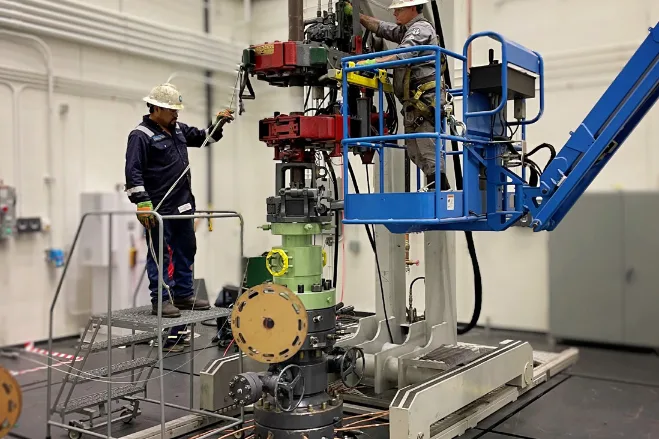

- Expro proposed an intervention program which featured mechanical and cased hole service interventions

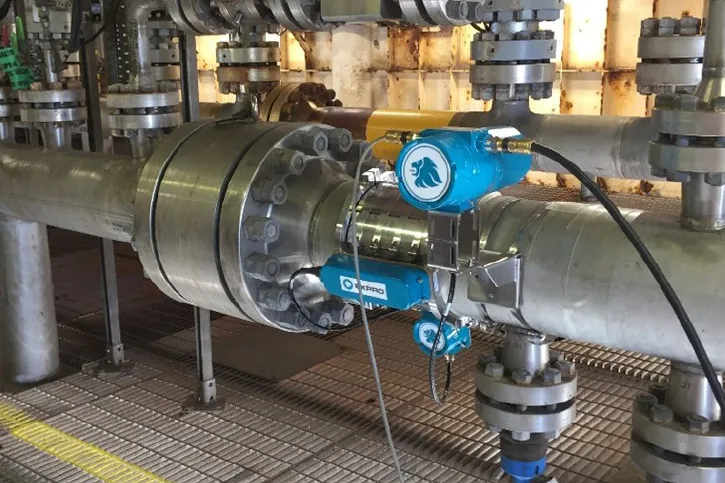

- The Mechanical Services intervention featured the deployment of customized Slickline Toolstrings to remediate the wellbore scale issue, with 2.5”OD and 3.50” OD Broaches being

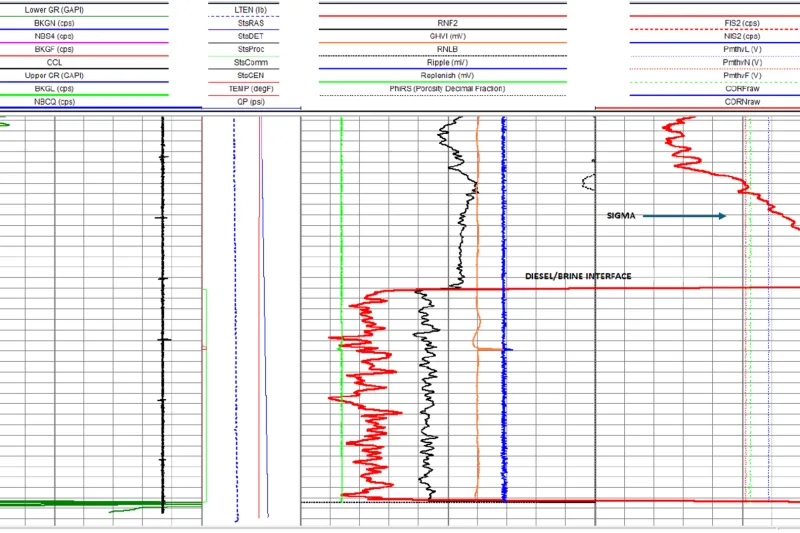

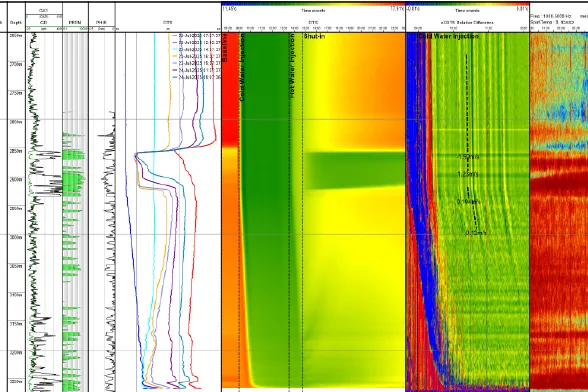

deployed - The Cased Hole Services intervention featured the deployment of a HT Production Logging Tool c/w Spinner, Pressure, temperature and gamma ray sensors to enable production profiling

Value to Client

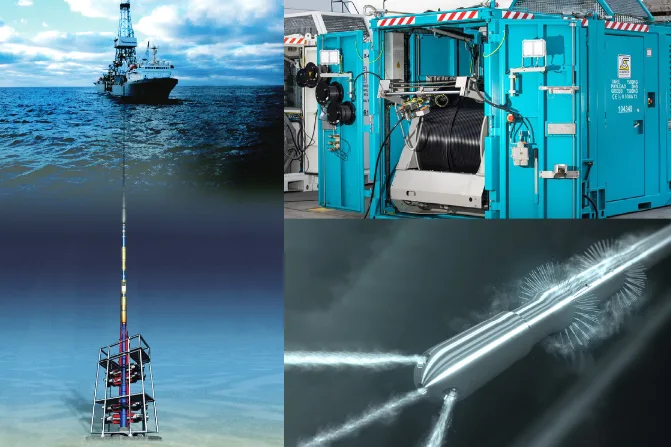

- The scale issue was successfully remediated to allow full bore access from the producing interval to surface

- Steam production increased from 3 tons of steam per hour pre intervention to 9 tons of steam per hour post intervention, a three-fold improvement

- A production profile across the producing interval was successfully acquired

- Expro’s successful intervention was recognized by the customer, and will now be replicated on other similar production optimization challenges in the field

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU