Case Study

Expro’s Octopoda® System reinstates B Annulus integrity via OBM displacement and resin deployment

Contact

In Brief

SCP in the B annulus was eliminated by introducing hydrostatic overbalance, followed by resin deployment to establish a mechanical barrier

Product Line

Region

Customer Challenges

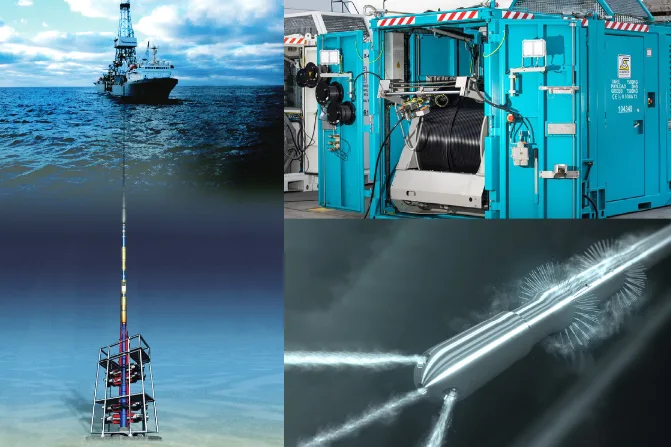

- Petroleum Development Oman (PDO) encountered sustained casing pressure (SCP) in the B annulus during the drilling phase, shortly after cementing the 7 5/8” production casing

- PDO engaged Expro to eliminate the SCP and place a resin barrier in the B annulus, enabling the well to be drilled to target depth, completed, and production brought online

- The B annulus contained oilbased mud (OBM), with the top of cement (TOC) at 720 m. Traditional lubricate-and-bleed methods were deemed ineffective at displacing the OBM with a resin compatible fluid

Expro Excellence

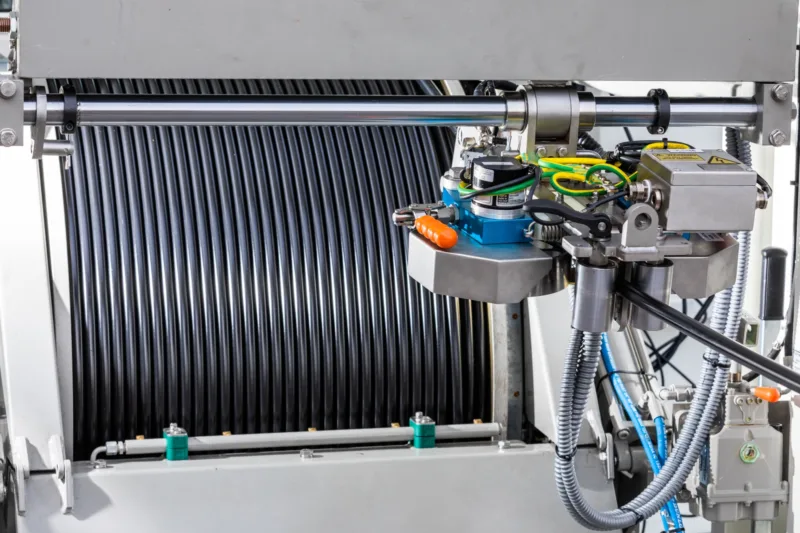

- OBM returns during initial hose deployment were highly viscous. The Octopoda® hose enabled effective break-up and mobilization of this fluid, proving critical to the success of the operation

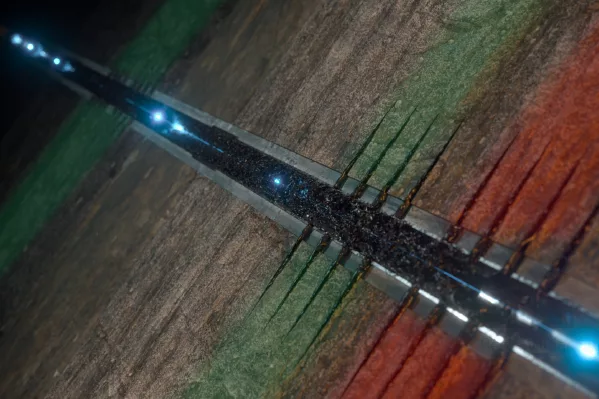

- Following the removal of viscous fluids, the hose was conveyed to a maximum depth of 64 m. Leveraging immiscible fluid dynamics and gravity-driven displacement, the OBM was efficiently swapped from the annulus, eliminating the need to reach TOC

- A total of 14.2 m³ of oil-based mud (OBM) was recovered from the annulus, and SCP was fully eliminated through a fluid swap, establishing hydrostatic overbalance

- After conditioning the annulus, 1.75 m³ of resin was circulated and allowed to freefall to the target depth. The Octopoda® system enabled this large-volume placement without exceeding MAASP, ensuring effective resin transport to the treatment depth

- Following the resin cure period, the B annulus was pressure tested to the recalculated MAASP, confirming integrity with a straightline pressure test sustained over 30 minutes

Value to Client

- SCP in the B annulus was eliminated by introducing hydrostatic overbalance, followed by resin deployment to establish a mechanical barrier

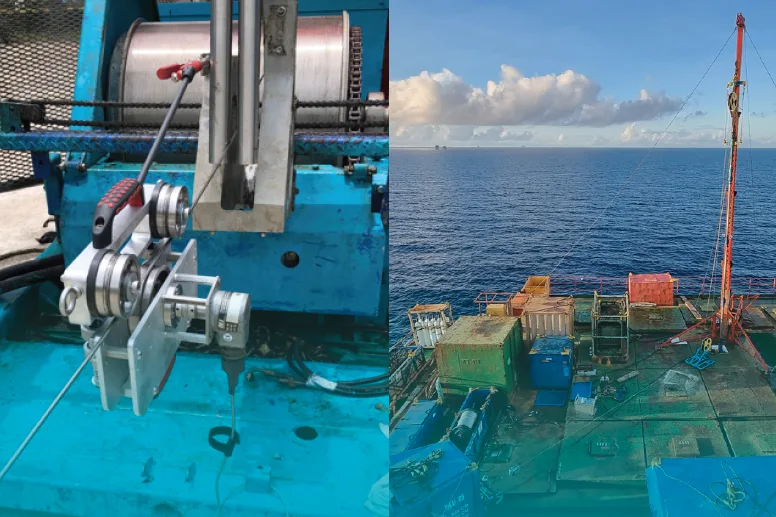

- The intervention was completed within three weeks from mobilization to demobilization, enabled by successful hose access into the annulus

- The client resumed drilling, completion, and production operations without requiring a costly workover rig intervention

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU