Case Study

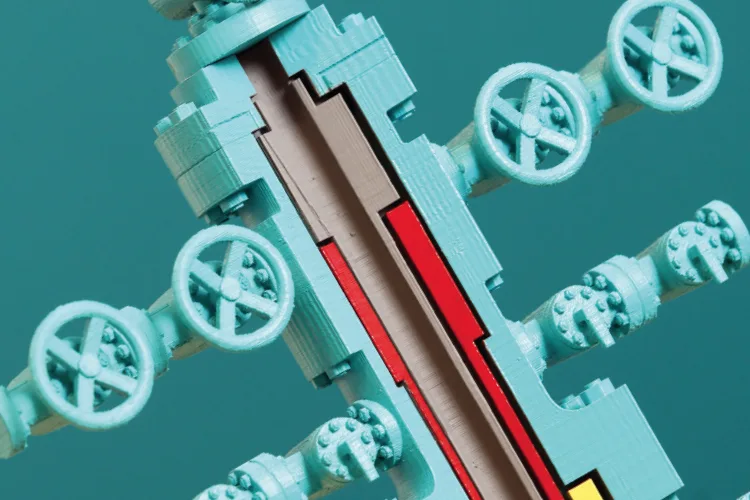

Cut your NPT and wire with the Kinley K2-Cutter

Contact

In Brief

The K2-Cutter was deployed, a successful cut made at the rope socket and the tool crimped to the wire for recovery to surface

Product Line

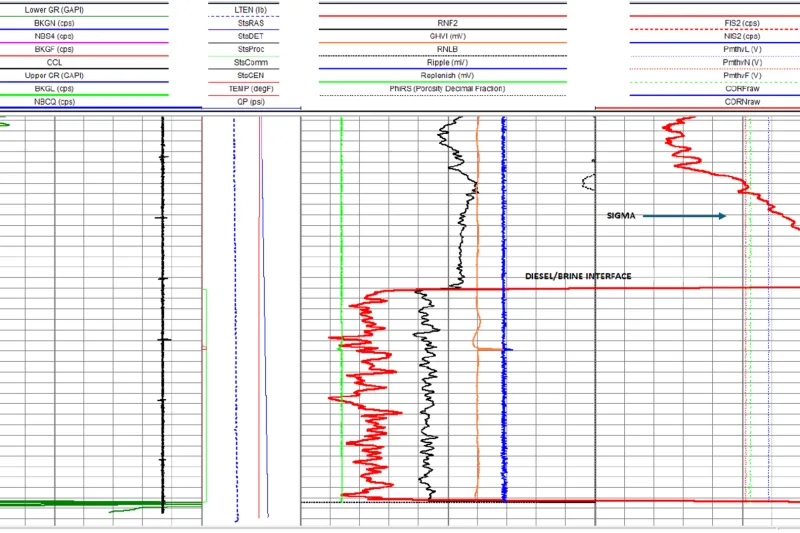

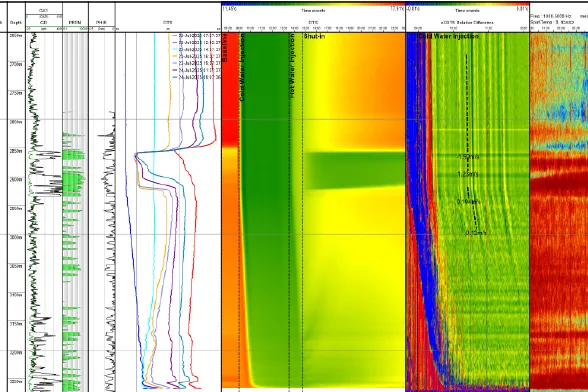

Customer Challenges

- During a rig based well abandonment program, a Slickline toolstring had become stuck in a tubing stump downhole

- After several hours of jarring, it was decided that recovering the wire in a controlled manner was the safest option versus continuing to jar and risk a wire break at surface or at an unpredicable depth downhole

- Due the possibility of a cutter falling near the fish, a reliable method of crimping the cutter to the wire for recovery post-cut was required

- The rig was on Non-Productive Time (NPT) until a solution could be found for the customer

Expro Excellence

- Expro’s Kinley K2-Cutter was chosen due to the necessity for rapid deployment

- The Kinley K2-Cutter has no explosives, no hydraulics and no lithium batteries, so it is easily transportable to any location, onshore, offshore or internationally

- Explosive alternatives would have taken days to mobilize - the K2-Cutter was at the heliport within hours of the call-out

- Full on-site operational checks were performed including a pre-deployment test cut, with the tool being reset and ready for deployment within minutes

- The K2-Cutter’s robust crimping mechanism ensures tool recovery with the cut wire

Value to Client

- The K2-Cutter was deployed, a successful cut made at the rope socket and the tool crimped to the wire for recovery to surface

- The wire was successfully recovered in less than 12 hours from the time the decision was made to stop jarring

- The abandonment program was subsequently able to continue with minimal NPT

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU