Case Study

Self orientating perforating gun system maximizes productivity

Contact

In Brief

Expro's solution allows our customer to successfully perforate their horizontal wells in the 0° vertical plane, to improve frac performance and to maximize production

Region

Customer Challenges

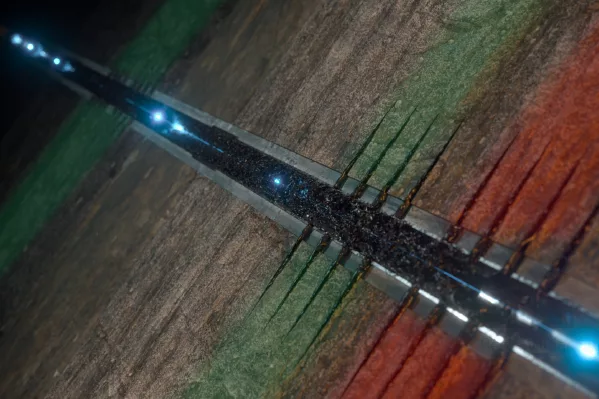

- Expro’s customer had a need to perforate their unconventional horizontal wells in the 0° vertical plane, to improve frac performance and to maximize production

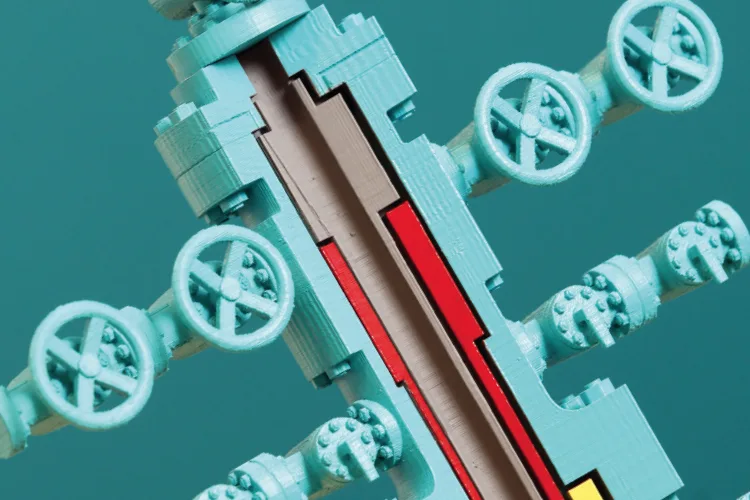

- Gun systems available locally could not meet the desired shot density and toolstring length requirements. The customer wanted to have a system that could run 10 guns per stage, with each gun having 2 shots 6 inch spaced with 0° phasing

Expro Excellence

- Expro have been performing pump down plug and perforation operations in Argentina since 2017

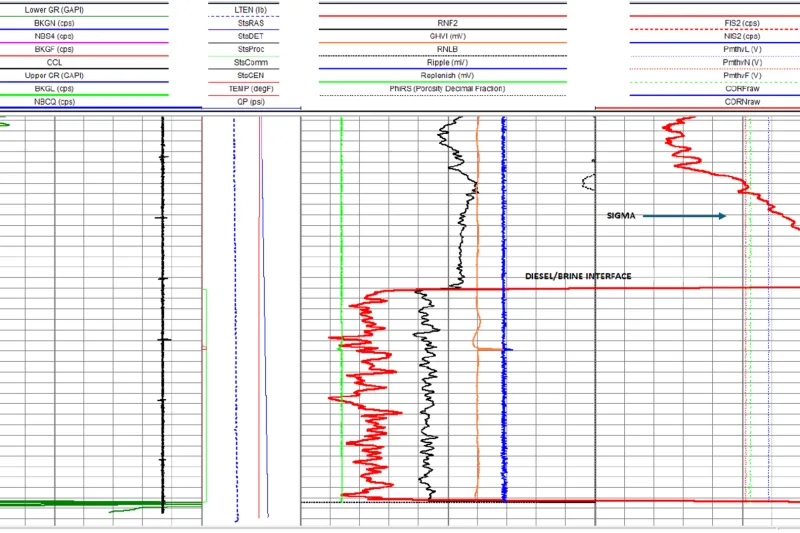

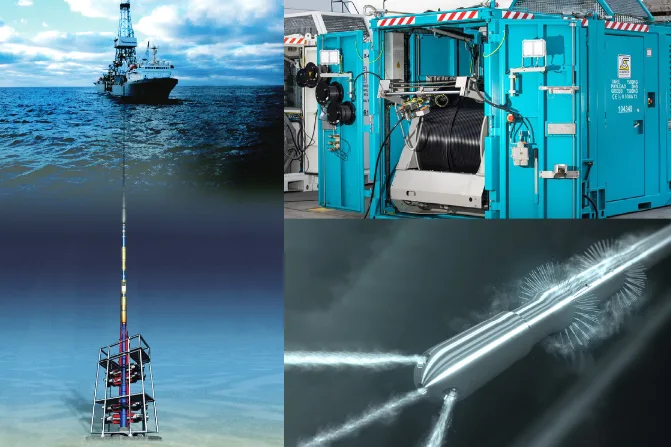

- The Expro Argentina team proposed a new self orientating gun system: gravity assisted, roller bearing loading tubes with scalloped gun carriers

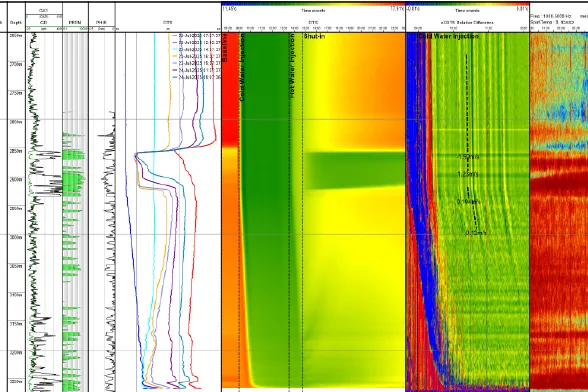

- The new gun system was tested in two wells, as part of which a Multi-finger Imaging Tool (MIT) was conveyed by tractor to verify shot orientation. The MIT survey confirmed 18 out of 20 guns were shot between 330°and 30°. This met the customer’s acceptance criteria

Value to Client

- Our customer now has a solution to successfully perforate their horizontal wells in the 0° vertical plane, to improve frac performance and to maximize production

- Our customer has also now deployed 248 oriented perforation stages in subsequent well intervention operations

- This solution has also enabled the customer to recover a well that was mistakenly drilled below the targeted shale pay-zone. By deploying the orientated gun system, the customer was able to perforate and frac up into the pay zone and subsequently produce the well

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU