Case Study

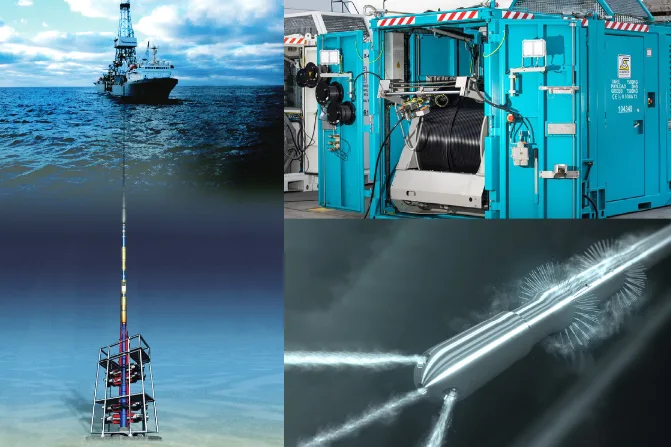

CoilHose delivers well injectivity remediation

Contact

In Brief

Restoring well performance: CoilHose injectivity remediation success

Product Line

Region

Customer Challenges

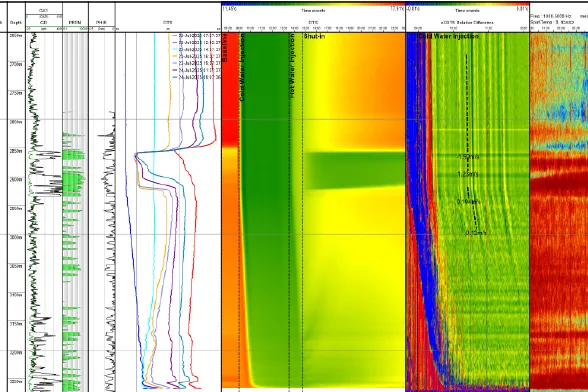

- Customer experienced significantly reduced injectivity in a water disposal well due to a build-up of material on the tubing walls, negatively impacting reservoir support and overall production from adjacent producing wells

- Conventional remediation using coiled tubing was considered, however this option was associated with high operational costs, extended well downtime and increased logistics planning

- Reduced water injection capacity into the reservoir was directly contributing to poor overall production performance across the field, creating an urgent need for a cost-effective and efficient solution to increase injectivity

Expro Excellence

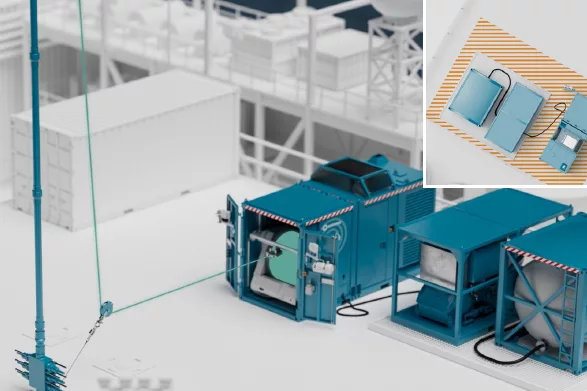

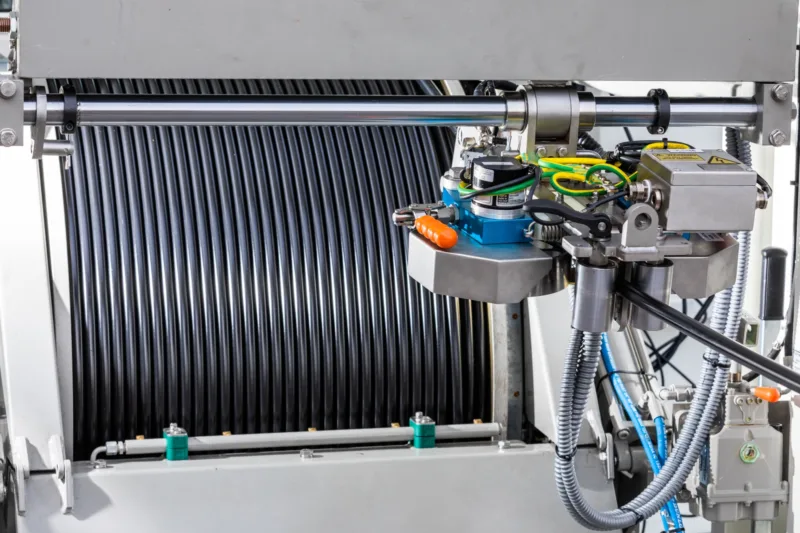

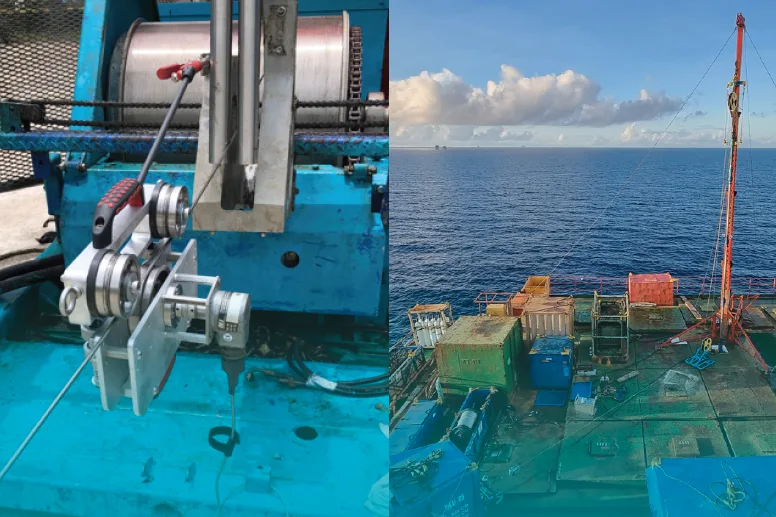

- Expro was engaged to deliver an alternative solution and leveraged its in-country CoilHose® package, enabling a rapid deployment

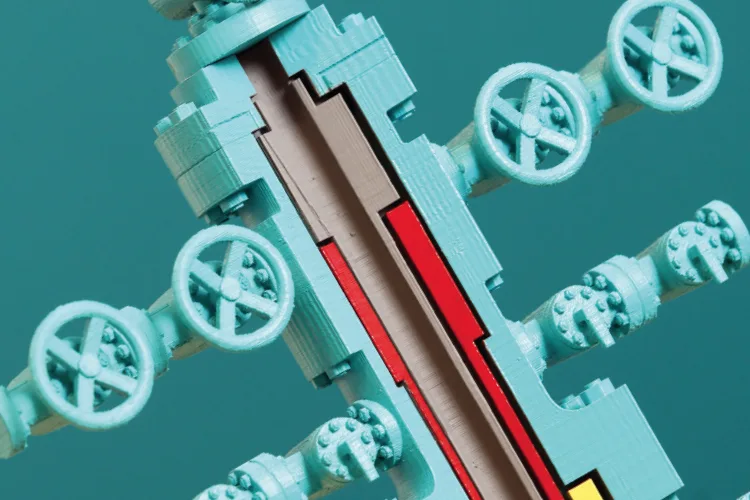

- A custom designed Bottom Hole Assembly (BHA) was engineered specifically to operate within the large bore completion, maximizing the hydraulic force and jetting efficiency to directly target material build up within the tubing

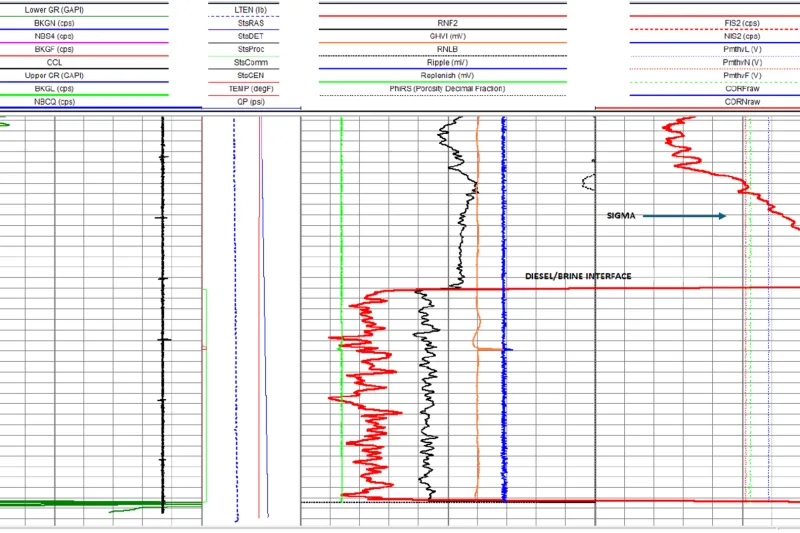

- Multiple cleaning runs were successfully completed using a combination of aromatic solvent and 15% HCL, effectively dissolving the hydrocarbon skim, and mineral organic scale deposits throughout the tubing

- Equipment and personnel were mobilized and executed four high energy impact jetting runs, ensuring full coverage of the affected interval tubing

Value to Client

- Expro delivered a fully integrated well intervention solution that combined rapid mobilization, custom BHA engineering, and high energy jetting deployed by a multi-disciplined crew structure

- Well operational downtime was minimized through efficiencies associated with rig up, deployment and rig down delivered from Expro’s Hydra well intervention model • Post intervention Injectivity results confirmed an increase in injected barrels of water per day into the reservoir. Improved injectivity restored effective reservoir support, contributing to enhanced production performance from surrounding wells

- The project demonstrated Expro’s ability to rapidly deploy an innovative, reliable and verifiable well intervention solution

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU