Case Study

Expro enables customer to optimize gas lift performance in 14 wells

Contact

In Brief

Expro unlocks production by deepening gas injection points in 14 wells on gas lift

Region

Customer Challenges

- Expro were engaged by a customer to provide solutions to improve production from 14 of their wells on gas lift

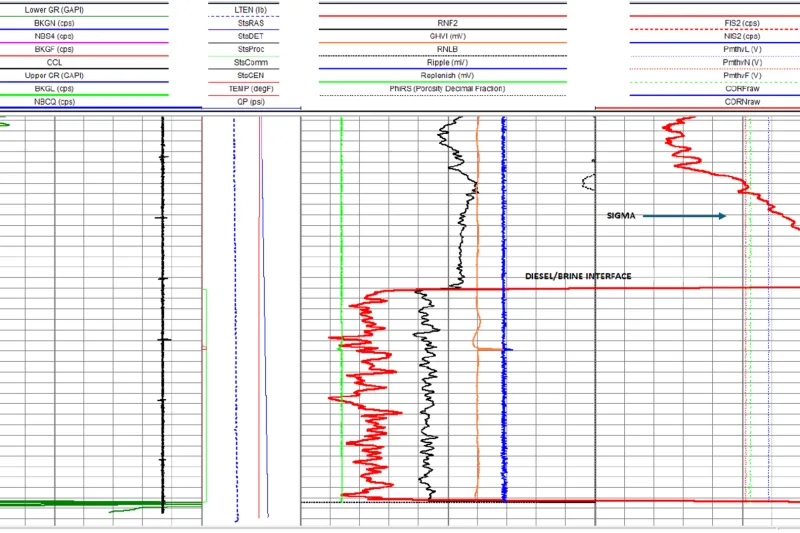

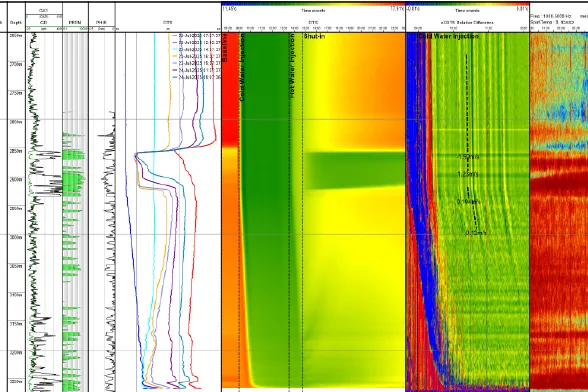

- Over time, the customer observed a decline in oil production from their wells due to depletion, and an increase in water cut which subsequently decreased the efficiency of the completion deployed gas lift systems

- The customer wanted the most effective and costefficient method for optimizing production and gas lift performance

Expro Excellence

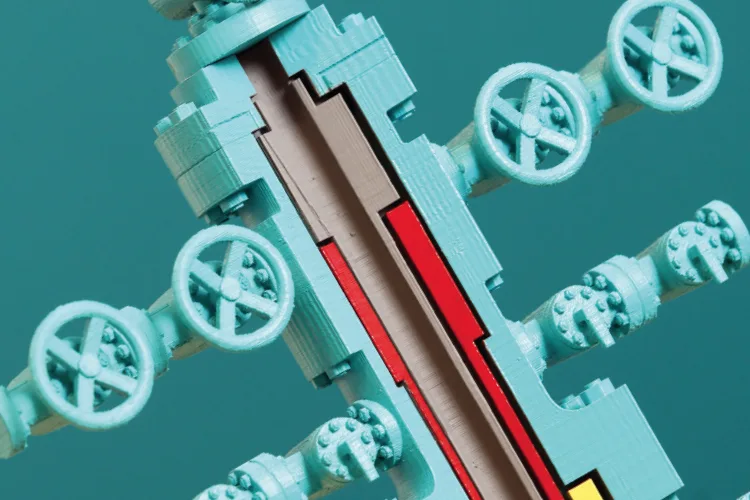

- The solution Expro proposed was to retrofit a new gas lift point below the lowest gas lift mandrels in all 14 wells

- Pre-job modelling indicated that the installation of the deeper gas injection point would significantly improve lift performance and well production

- The customer used a slickline deployed Expro Kinley Perforator tool to install 16/64” orifice check valves up to 600ft below the lowest gas lift mandrels

- All wells were prepped prior to the remediation by drifting the well bore and bleeding down the annulus pressure to create a slightly overbalanced condition

- Expro has a significant global track record with over 20,000 runs with the Kinley Perforator tool

Value to Client

- The customer was able to optimize lift performance, with production increases observed of up to 20% per well

- Deployment of the Kinley Perforator on slickline enabled the customer to intervene into the well in the most operationally efficient manner

- Expro saved the customer significant intervention costs by using the Kinley Perforator vs a traditional gas lift pack-off assembly, with competing solutions requiring additional hardware in the wellbore with a smaller ID restriction

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU