Case Study

CoilHose™ successfully restores production in a water loaded well

Contact

In Brief

CoilHose ™ restored production in a water-loaded well, delivering fast results with a simple, reliable intervention

Region

Customer Challenges

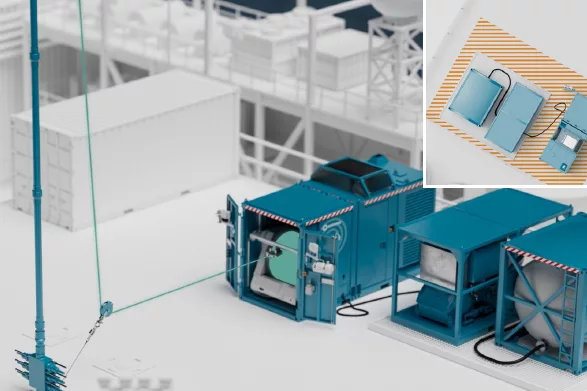

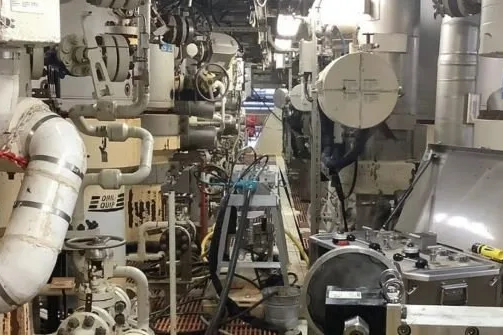

- Offshore operations in Indonesia are challenged by limited deck space, reduced crane capacity, and increasing economic pressure as assets reach maturity

- In this case, the customer had a shut‑in well that could not flow naturally due to hydrostatic overbalance. Given the platform’s small footprint and the need to coordinate multiple service providers, both planning and execution demanded extensive detail, careful scheduling, and precise logistical coordination to successfully deliver the project

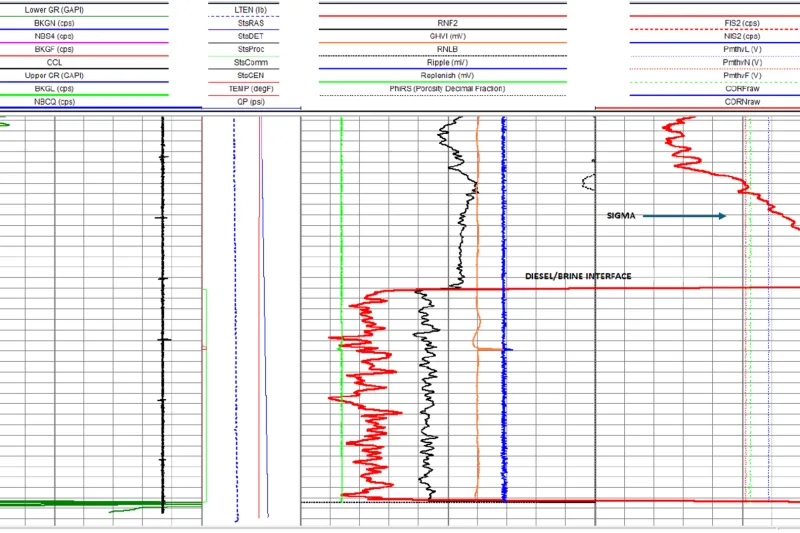

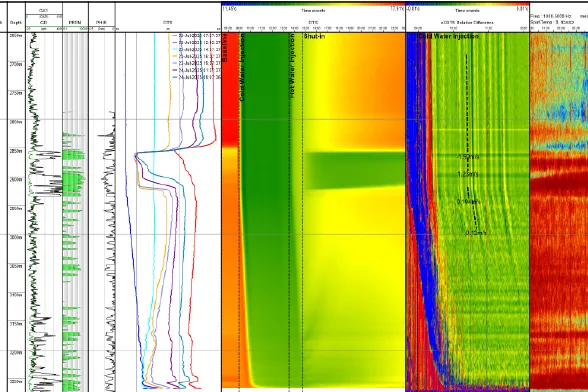

- The well had been shut in since 2024, and the client anticipated start‑up difficulties due to the presence of high‑density fluids in the target production zones

- The project required a full suite of well intervention services, including Slickline, E‑Line, and the capability to effectively unload completion fluid from the well

Expro Excellence

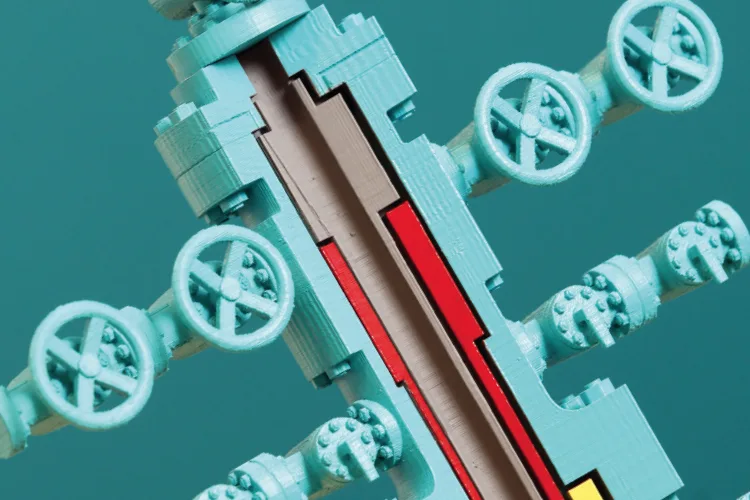

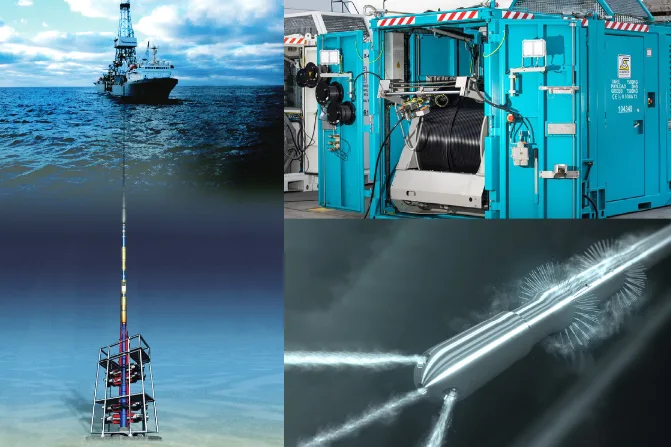

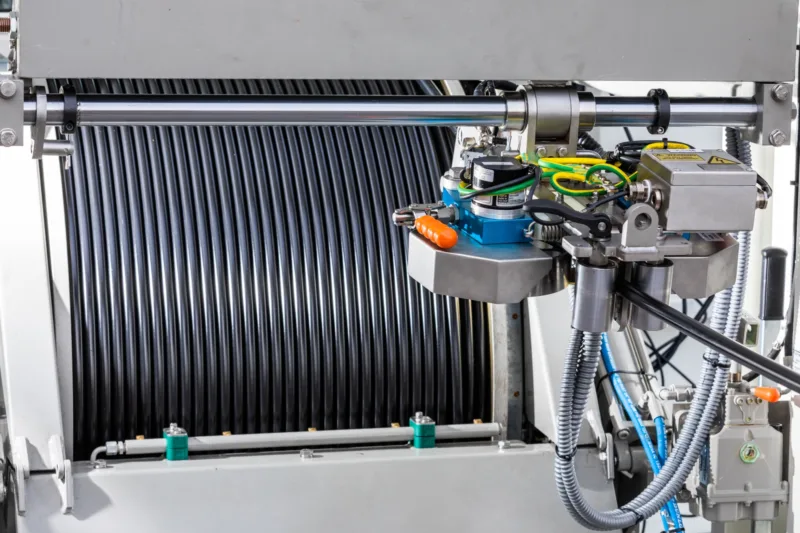

- To address these challenges, Expro’s Hydra solution was selected. This innovative system eliminates the need for separate Slickline, E-Line, and Coil Tubing packages from multiple vendors. Hydra integrates these services into a single multi-Well Intervention system, utilizing CoilHose™ as an alternative to conventional Coiled Tubing

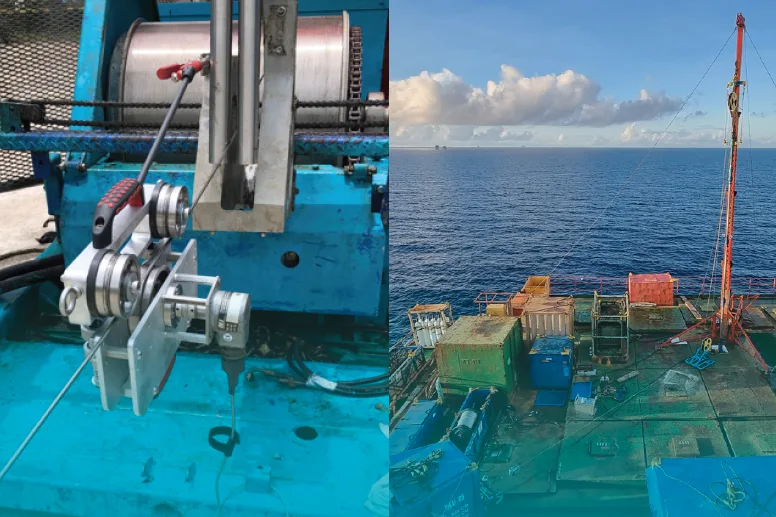

- The Hydra solution enabled full integration of mechanical Slickline for plug retrieval, E-line for SSD manipulation, and CoilHose™ for nitrogen unloading into a single integrated system via the Well Intervention mast. Front‑end modules were easily swapped within the deployment unit, enabling seamless service transitions and maximizing efficiency. This reduced footprint and POB while delivering faster, more streamlined intervention operations. By contrast, conventional standalone packages would have required multiple mobilizations and repeated rig-up/rig-down cycles, significantly extending this project

Value to Client

- Excellent cooperation and collaboration between Expro and the client’s intervention team during the project

- The Hydra solution significantly improved rig‑up and rig‑down efficiency, with operations completed faster and supported by a multidisciplinary team working with a reduced POB • A total of 39 bbl of well fluid was successfully recovered, enabling the well to be safely returned to production at 2.2 MMSCFD

- The intervention was executed with zero downtime, no NPT, and no HSEQ incidents, delivering maximum value to the client

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU