Case Study

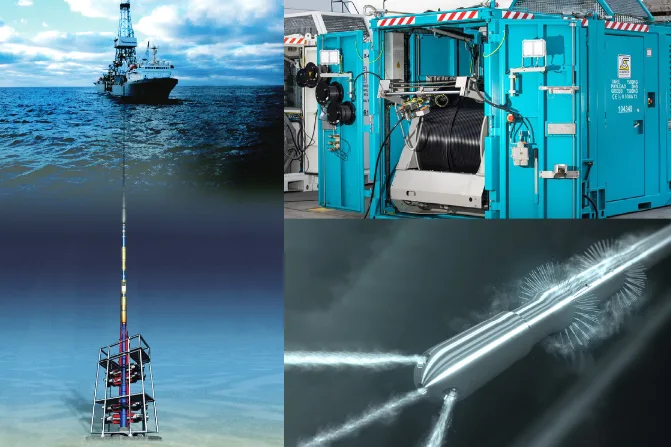

CoilHose™ system used to re-instate gas lift functionality

Contact

In Brief

Expro supports customer to re-instate production from north sea well

Customer Challenges

- An Expro customer was experiencing production issues with one of their North Sea wells

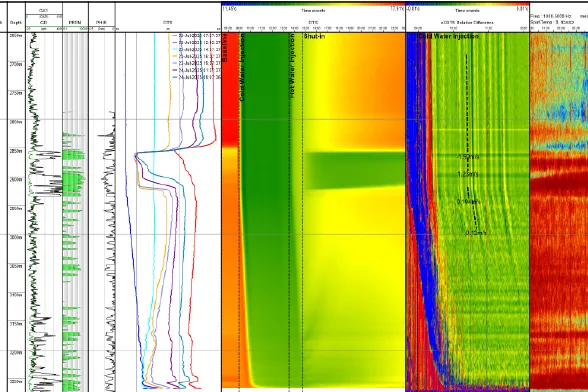

- Oil and associated gas production was decreasing due to high water cut caused by water injection support in the reservoir. Gas lift was then required in order to maintain oil production

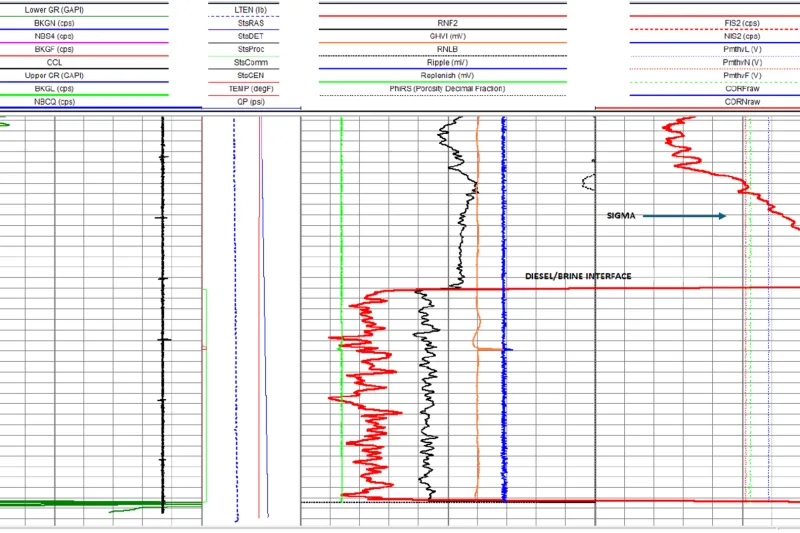

- The well was equipped with a dual string completion, the main string was for hydrocarbons production, the secondary string was for gas injection. Unfortunately, gas lift was not in service because the Downhole Safety Valve in the gas injection string had lost its function due to debris ingress (likely grease and/or pipe dope) in the valve

- Previous attempts to re-instate the Downhole Safety Valve functionality by pumping diesel and using Slickline conveyed brushing was unsuccessful

Expro Excellence

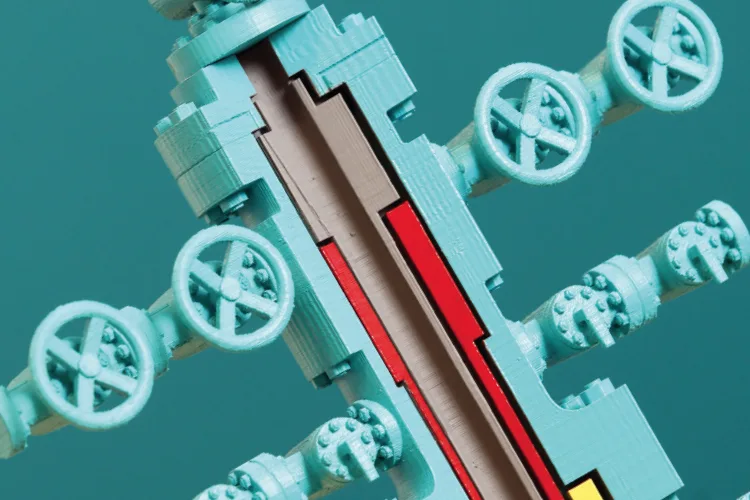

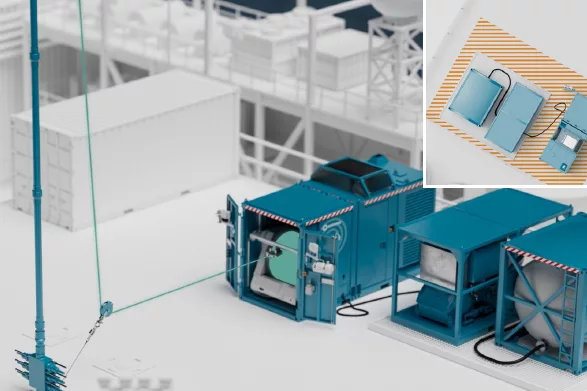

- Expro’s CoilHose™ Light Well Circulation System is a hybrid well intervention system that combines the operational efficiency of a wireline deployment with the capability to perform a range of nitrogen and fluid pumping applications

- The CoilHose™ solution was selected because of its small footprint, modest crew requirements and capability to be rigged up and deployed quicker than the competing Coiled Tubing option

- A total of two runs in hole were made with the CoilHose™ system, with the CoilHose™ BHA featuring a combination of side nozzles and a turbo end nozzle

- A 3rd Party Slickline deployed Closure Assist Tool was run between and after the CoilHose™ jetting runs to exercise the DHSV flow tubes

- The Downhole Safety Valve was successfully jetted to remove the debris and re-instate its functionality

Value to Client

- The customer was able to re-instate the functionality of the Downhole Safety Valve in the gas lift string

- The gas lift string has subsequently been brought back into service to increase oil production from the well

- The operation was completed more efficiently and with a lower carbon footprint than the alternative Coiled Tubing solution

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU