Case Study

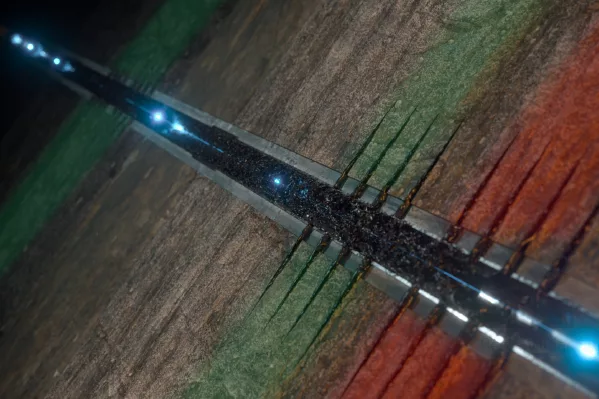

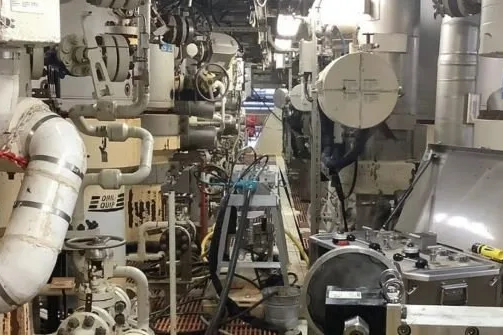

World First N2 unloading of well using CoilHose™ on Riserless Well Intervention vessel

Contact

In Brief

World's first well to be successfully unloaded with CoilHose™ using RLWI

Product Line

Customer Challenges

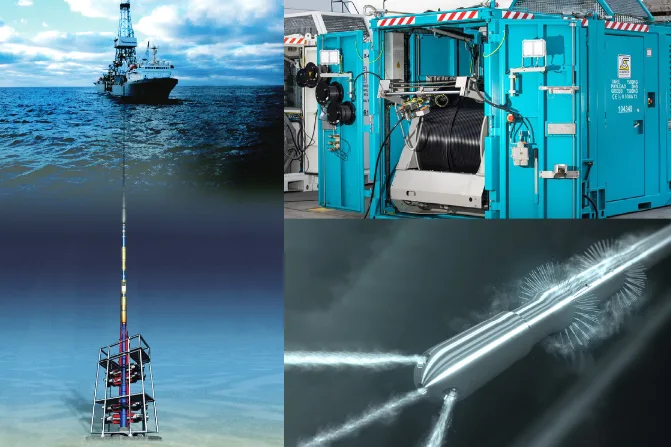

- Equinor had a newly completed well that had been left with a full column of brine during the completion phase. Simulations showed that N2 gas lift was necessary to start production

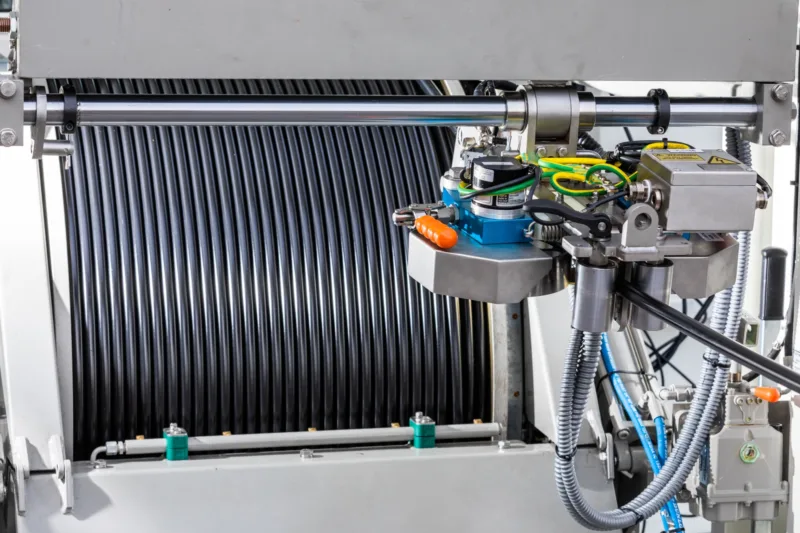

- The alternative to CoilHose™ would have been Coil Tubing which is logistically challenging, High POB and very much weather dependent

- Equinor had previously worked with Expro and have a good understanding of our CoilHose™ technology and our ability to perform open water intervention from RLWI with a limited footprint and less POB

Expro Excellence

- World’s first well to be successfully unloaded with CoilHose™ using RLWI

- CoilHose™ was positioned at a depth of 2,150 mMD while the well was unloaded over a period of 7hrs

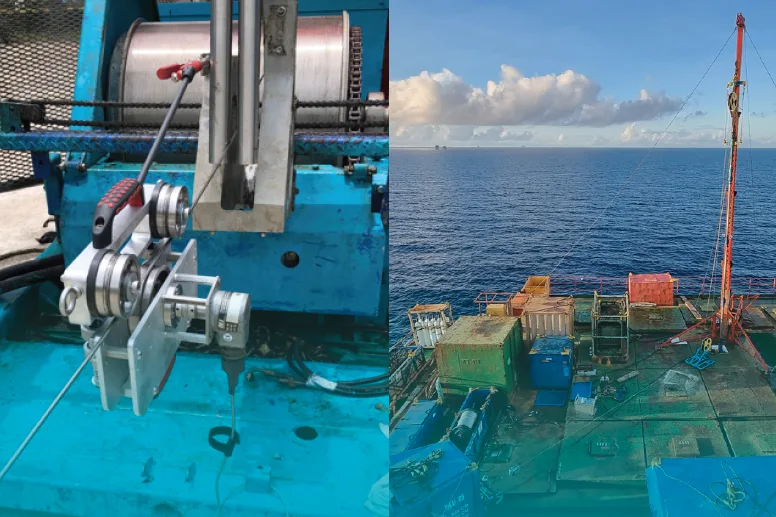

- Expro deployed a ‘hybrid’ CoilHose™ package to work in conjunction with the customers preferred wireline vendor resulting in a fully integrated service delivery platform

- The project was completed safely and ahead of planned timings

Value to Client

- The project duration was significantly improved by utilizing the CoilHose™ solution compared to traditional Coil Tubing

- A reduction in carbon footprint through delivery of an integrated solution

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU