Case Study

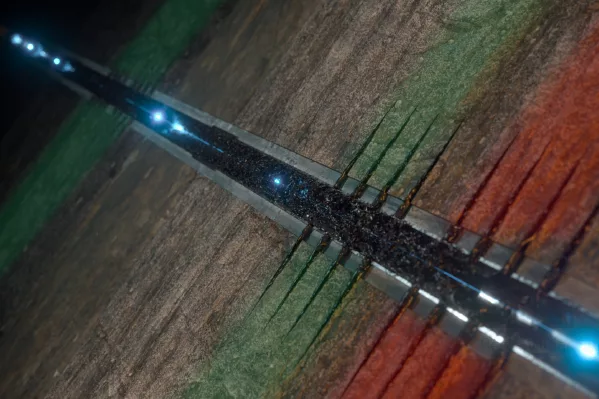

CoilHose operation in Malaysia completed within 12 hours

Contact

In Brief

Expro delivers first CoilHose operation in Malaysia to support well test operation

Product Line

Region

Customer Challenges

- Expro's customer had requested mobilisation of conventional coil tubing as a contingency to lift the overbalance cushion in a newly completed well

- Operations were planned to be conducted on the critical path with the use of a drilling rig

- Incumbent supplier was not able to provide a coil tubing package within the requested time frame and therefore posed a potential delay to the work scope which would impact delivery of the entire project

- Expro's CoilHose was fast-track mobilised to provide the required solution

Expro Excellence

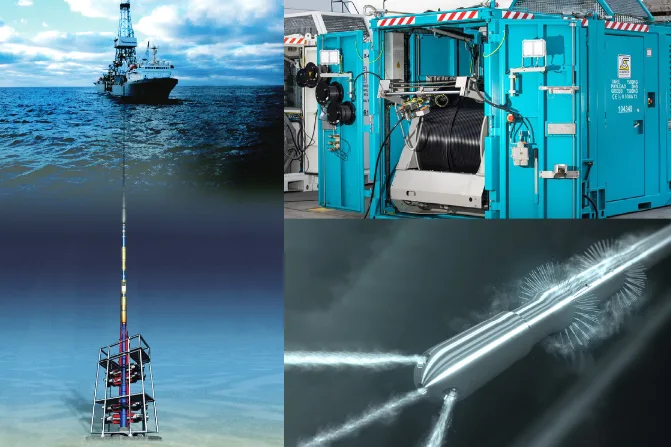

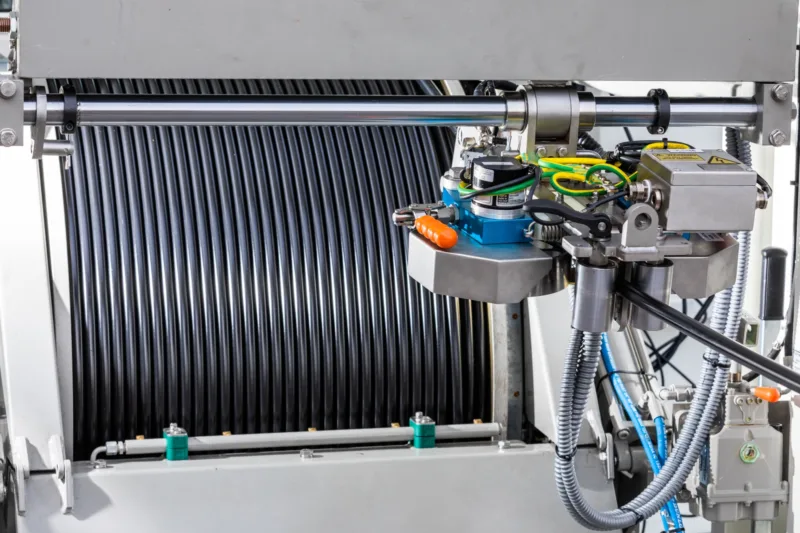

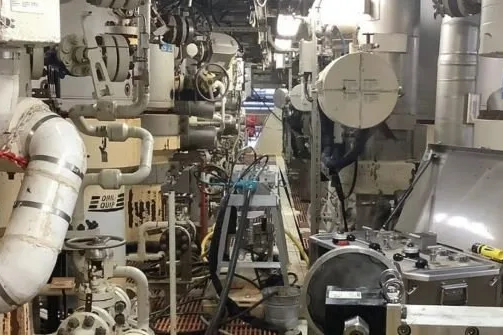

- Expro provided a proposed engineered solution with its latest 3/4" OD CoilHose Light Well Circulation System

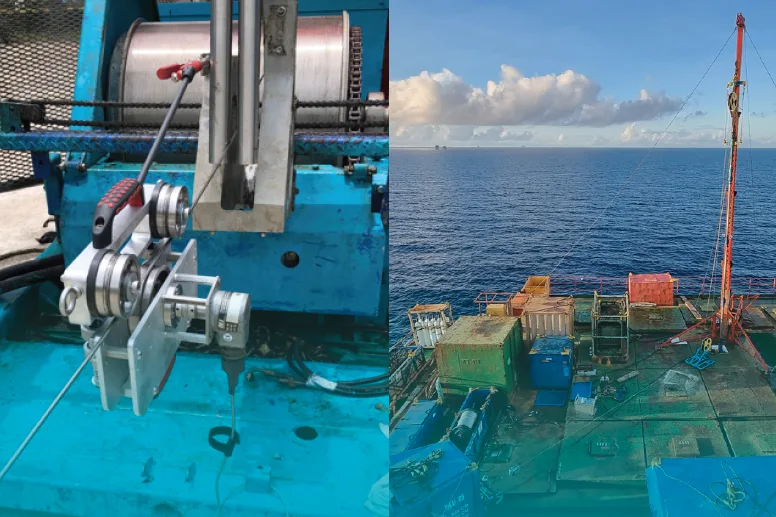

- Equipment was prepared and mobilised to the region within 21 days where a successful Site Integration Test (SIT) was completed prior to mobilisation to the rig

- Key interfaces with the rig and other key suppliers were successfully managed

- Expro delivery met the customer expectations and the project continued without delay

Value to Client

- Overall delivery of the well without impacting the project timeline

- Equipment was mobilised on a scheduled vessel which removed the requirement for a chartered vessel that would normally be required for conventional coil tubing

- CoilHose has reduced complexity, footprint and weight compared to traditional coil tubing equipment which allowed for optimum planning through to operational execution and de-mob

- Like for like operational timings were significantly reduced and performed with a multi-disciplined reduced POB

- As a result, the CoilHose operation reduced well over 75% of the like for like operational CO2e emissions

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU