Case Study

Cost-effective re-perforating on satellite platforms with limited footprint and crane restrictions

In Brief

Expro offer cost-effective re-perforating on satellite platforms with limited footprint and crane restrictions

Product Line

Region

Customer Challenges

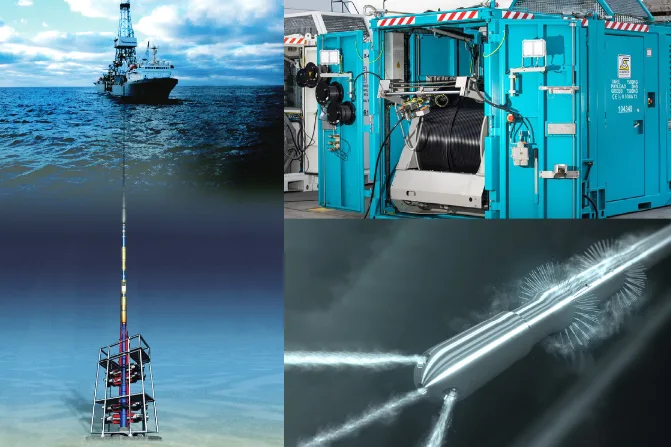

- A major operator in Asia wanted to improve well performance by re-perforating selected wells; the objective was to reduce skin factors so flow rates could be increased

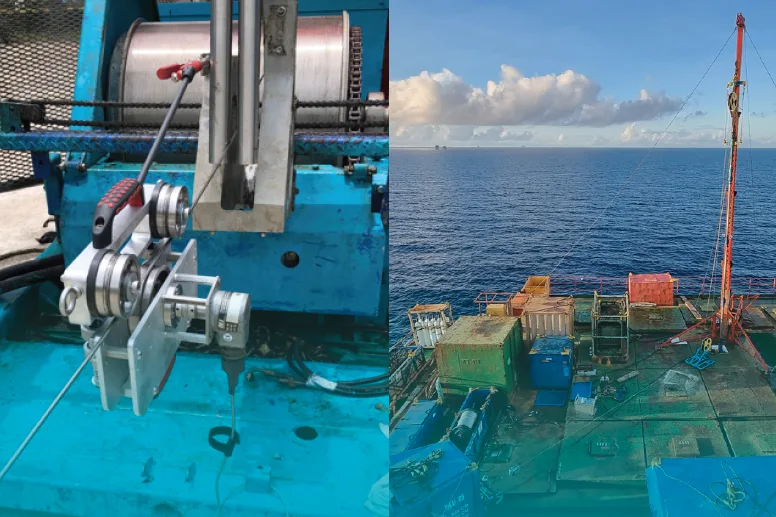

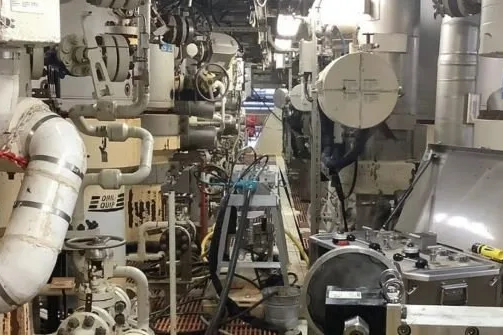

- The wells requiring work were on compact footprint production platforms that did not have cranes designed for heavy lifts; this proved a challenge as conventional slickline packages or e-line packages would have exceeded crane lifting capacities, which in the past had prevented such operations unless support barges had been deployed

- The client approached Expro to provide a one stop solution and service, using an established track record in slickline perforating

Expro Excellence

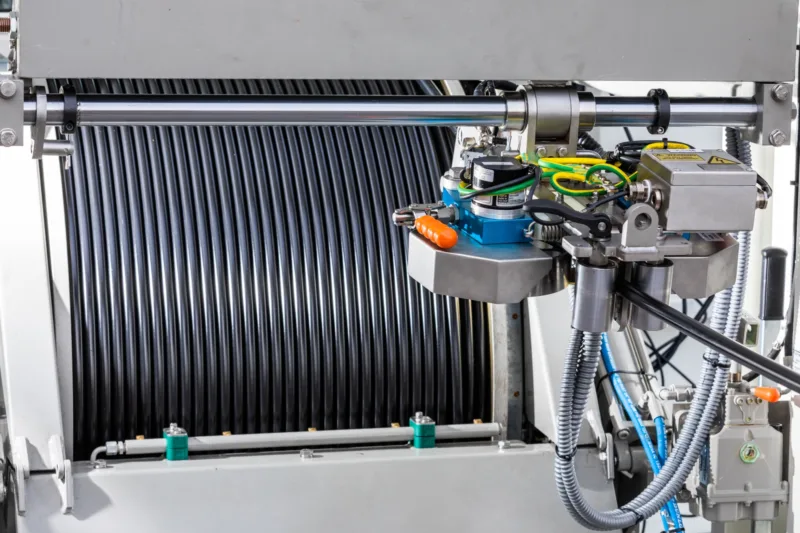

- Expro devised a full-service solution which comprised mobilising a lightweight winch package and lightweight mast package, along with specialised pressure control equipment

- The lightweight mast was run in tandem from the slickline power pack, allowing additional space on the top deck

- Expro's memory trigger was used along with selected gun system and charges required to meet the objectives

- Multiple successful perforation runs were carried out on depth using Expro's depth correlation system to ensure accuracy

Value to Client

- Avoided costly mobilisation of a well services vessel with crane capabilities

- Reduced costs - deployment of multi-skilled personnel and equipment from one source

- The client was able to double production; exceeding initial expectations

Expro's approach was to mobilise compliant lightweight equipment so the platform infrastructure could be used for the offloading of all equipment required, thus meeting the client's objectives

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU