Case Study

Expro’s C-Annulus intervention prevents gas migration

Contact

In Brief

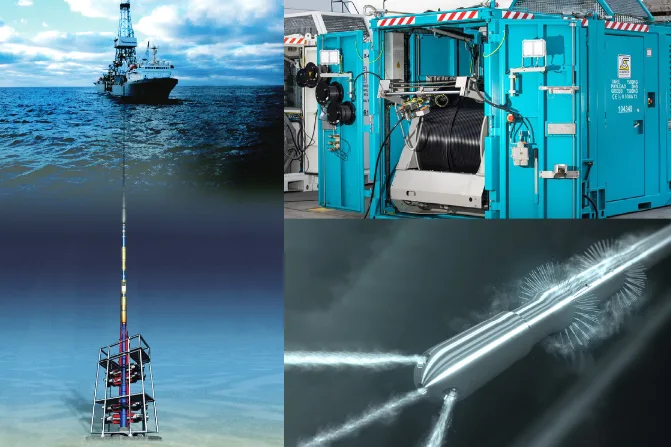

This is a world record of depth reached with Expro’s Annulus intervention system reaching 300 meters

Product Line

Region

Customer Challenges

- The client had the risk of a gas migration through the threads of a non-gas tight casing in a gas well. Due to the risk of communication of gas to the C-annulus in a high production gas well, it was required to assure a mechanical seal at the casing shoe and a hydraulic seal up to surface

- As the full hydrostatic column was close to the collapse pressure of the inner casing, it was required to work with low densities to perform the operation. There was no information about the physical location of the Top of Cement (TOC) in the C-annulus or the diameter of the open hole section behind the inner casing which complicated the determination of volumes to be pumped even more

- With full cooperation of our client, we determined a way to calculate the TOC based on calculations of the density gradient and pumped volumes which allowed us to control the density value in front of the casing shoe and set a resin plug at the external casing shoe depth

- The C-annulus was fully sealed, and the client was able to assure the integrity of the well for the rest of it’s productive life

Expro Excellence

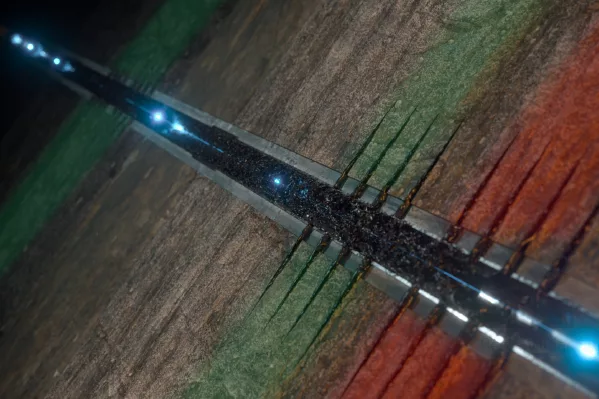

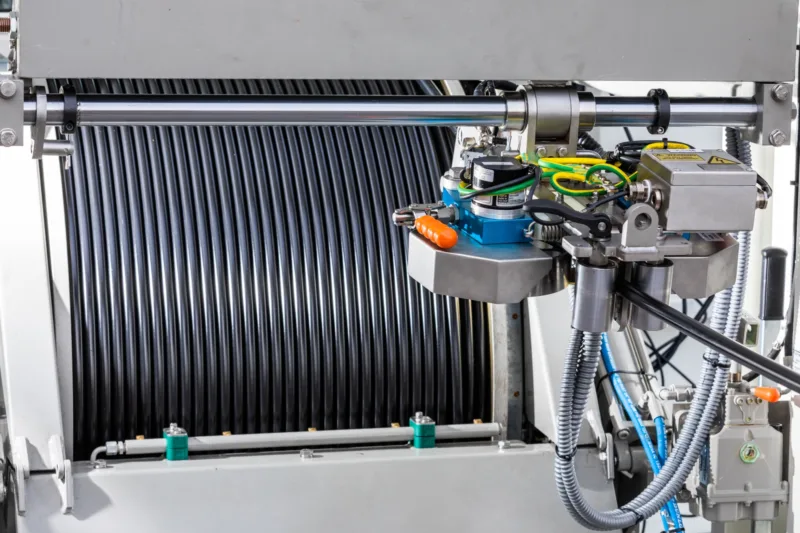

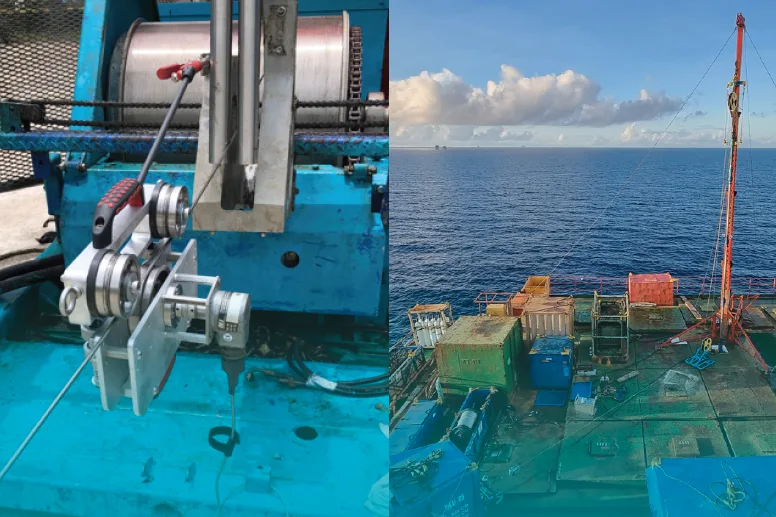

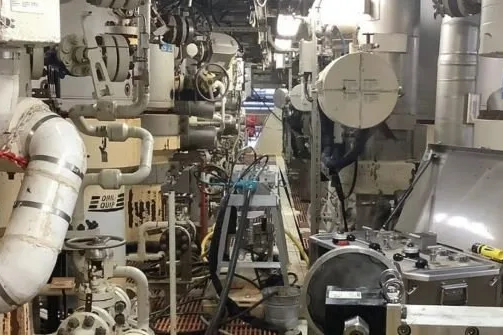

- Expro’s Annulus intervention system was run in the C-annulus to a depth of 300 meters to create circulation and to set a resin plug at the conductor casing shoe

- By monitoring the pumped and returned volumes and densities, it was possible to determine the correct depth of the TOC, which allowed the client to re-evaluate the maximum pressure to be handled in the C-annulus. There was no other way to evaluate as no cement bond log was taken after the inner casing was cemented in the C-annulus

- By pumping from the bottom of the C-annulus, it was possible to reduce the resin pumping time and we assured the correct fluid density distribution of the brine to guarantee the correct setting depth of the resin plug. This is not possible while pumping from surface as heavy brine gets diluted in fresh water generating a uniform density column in the C-annulus

- All operations were performed while the well was producing

Value to Client

- This is a world record of depth reached with Expro’s Annulus intervention system reaching 300 meters

- By securing the C-annulus the client was able to keep the well in production for the rest of its estimated productive life

- The alternative solution for the client would have been a full workover intervention or well abandonment

- To maintain production under the current conditions, before our Annulus intervention system was utilised, there was a risk that in the inner casing would collapse, which would lead to a hazardous situation and the plug and abandonment of the well

- Expro were able to flow the well and this resulted in savings of $1m in intervention costs for our client

- It was not necessary to stop production while performing the annulus intervention operation

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU