Case Study

CoilHose provides Landing String hydrate contingency solution for subsea gas development

Contact

In Brief

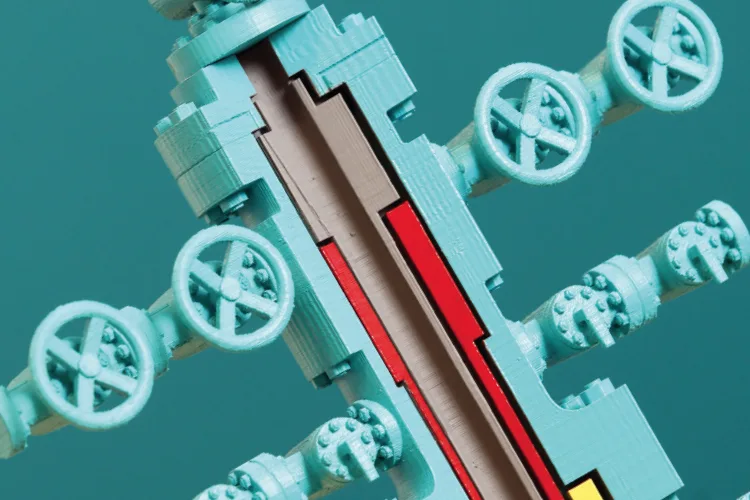

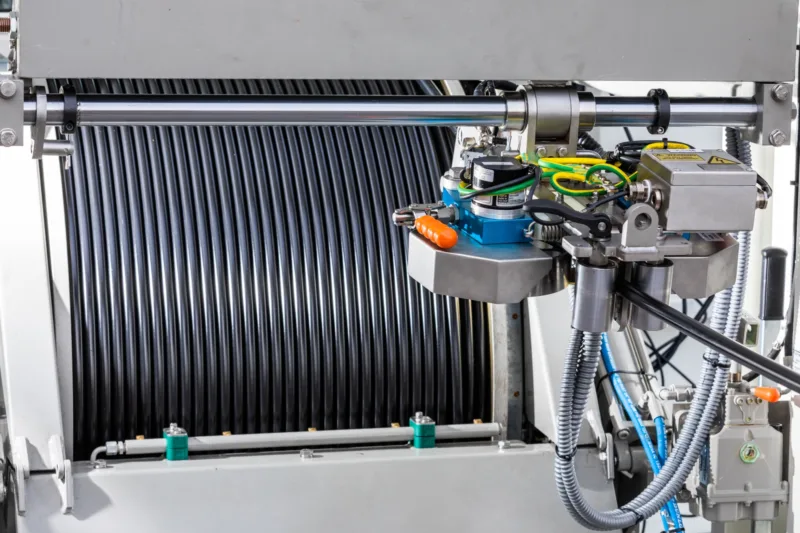

Subsea Landing String hydrate remediation solution

Customer Challenges

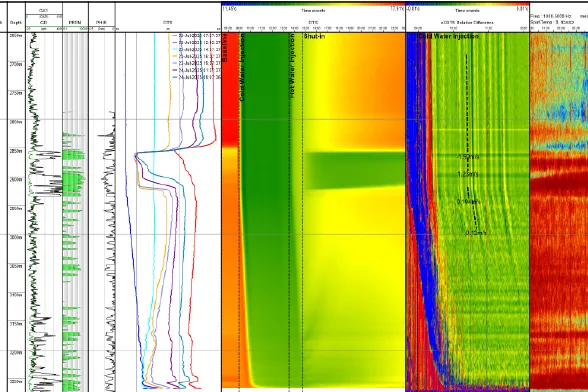

- A customer was planning a drillship based drilling, completion and well test campaign on a batch of high rate gas subsea wells

- Following analysis of the well parameters, sea temperatures and hydrate formation curves it was established that there was a significant risk of hydrate formation in the Landing String during the completion and well test phases

- A contingency plan was thereforerequired should hydrates be encountered in the Landing String during these phases

Expro Excellence

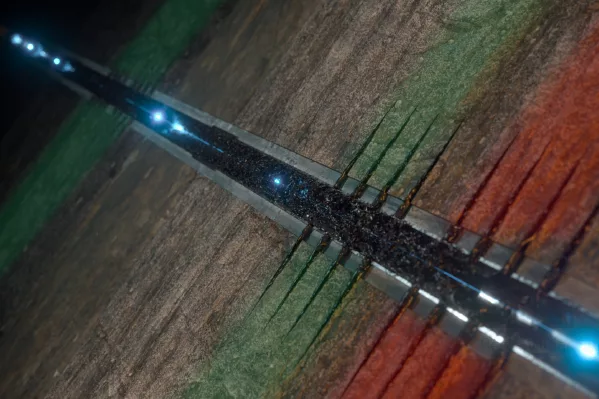

- An engineered solution was developed for the customer to cater for the different well parameters and hydrate formation scenarios that could be encountered during the campaign

- The customer had previous experience with using mono ethylene glycol (MEG) for hydrate removal, so a specialized MEG jetting tool was configured for the CoilHose BHA

- CoilHose was selected over competing coiled tubing and wireline milling methodologies

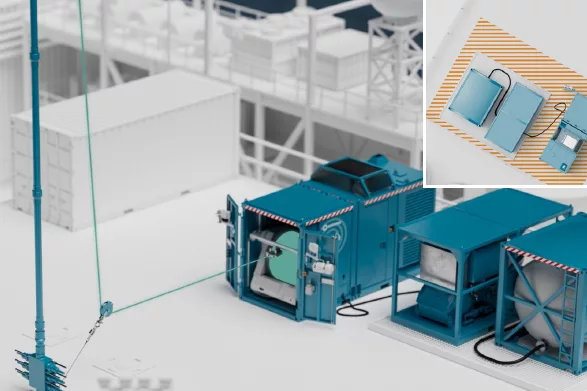

- Key factors in the selection of CoilHose were rig-time saving, operational efficiency and a compact rig-up

Value to Client

- The customer had previous experience with using mono ethylene glycol (MEG) for hydrate removal, so a specialized MEG jetting tool was configured for the CoilHose BHA

- CoilHose was selected over competing coiled tubing and wireline milling methodologies

- Key factors in the selection of CoilHose were rig-time saving, operational efficiency and a compact rig-up

Contact

For further information, please contact wellintervention@expro.com.

©2025 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU