Case Study

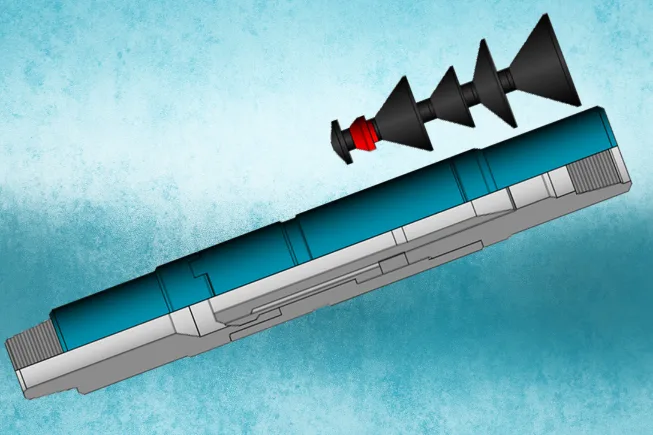

Fully automated Cement Head allowed for increased circulation & displacement rates through the top drive, improved operational efficiency and red zone management

Contact

In Brief

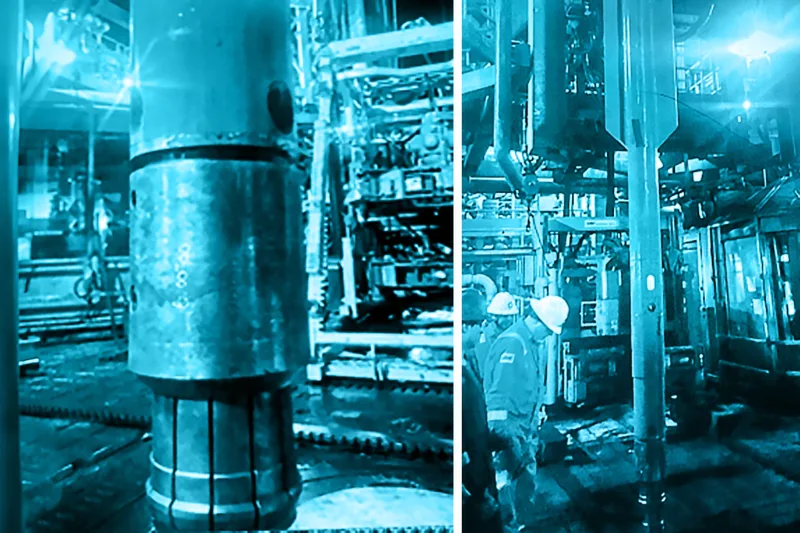

Major NOC in the Kingdom of Saudi Arabia proves safety and efficiency of Expro's wireless cement head and Skyhook systems

Product Line

Region

Customer Challenges

- The customer was interested in reducing Red Zone exposure for their personnel

- The customer was experiencing inefficiencies due to planned shutdowns, restricted circulation and displacement rates

- This resulted in a requirement to rig down casing running equipment prior to the cement job

- Enhanced efficiency in transition from casing running to cementing operations while keeping the wellbore dynamic and displacing through the top drive while connected to the Cement Head

Expro Excellence

- Expro’s Blackhawk® Gen X Wireless Cement Head with Skyhook® eliminated red zone exposure for personnel throughout the cement job

- Our Blackhawk® Gen X Cement Head allowed the client to circulate and condition the wellbore with righ pumps@ 12bpm prior to the cement job and displaced cement at 13bpm through the top drive

- Our technology allowed for a seamless rig up operation with our Blackhawk® Gen X handled as final casing joint

Value to Client

- The operation proved that the operator was able to achieve their primary cement job while keeping personnel out of the red zone and eliminating all man-riding operations; safeguarding the rig personnel against increased risk during the entire course of the operations

- Increased circulation and displacement rates through the top drive were achieved, creating better mud removal and saving valuable rig time

- The customer was able to quantifiably prove that fully automated cement heads allowed for reduced wellbore fluids static time and that circulation could begin immediately after casing is on depth

- The hanger was able to be landed out immediately upon completion of the cement job, without the requirement to first remove a conventional cement head, as the assembly was connected to the top drive allowing for manipulation of the casing string

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU