Case Study

CBI™ tool significantly enhances hole cleaning resulting in 40% ROP enhancement for Middle East operator

Contact

In Brief

This CBI™ technology was effective in improving hole cleaning. This enabled faster ROP and allowed the drilling assembly to be pulled out of hole freely on elevator without back reaming or getting stuck

Product Line

Region

Customer Challenges

- A Middle East operator was planning a 5,000 ft. 8 ½” horizontal section to be drilled in Harmaliyah Field and sought a method to avoid the typical problems of these wells such as holecleaning, high torque and drag and wear and tear on drill string components. The customer was especially keen to reduce time spent on back reaming out of the hole due to cuttings build up

- Cuttings packoffs on previous wells resulted in the drill string getting mechanically stuck, wasting time and money to free. Expro recommended the use of 22 of our patented CBI™ Cutting

Bed Impeller tools, to improve hole cleaning in the buildup sequence from 80 to 95 degrees

Expro Excellence

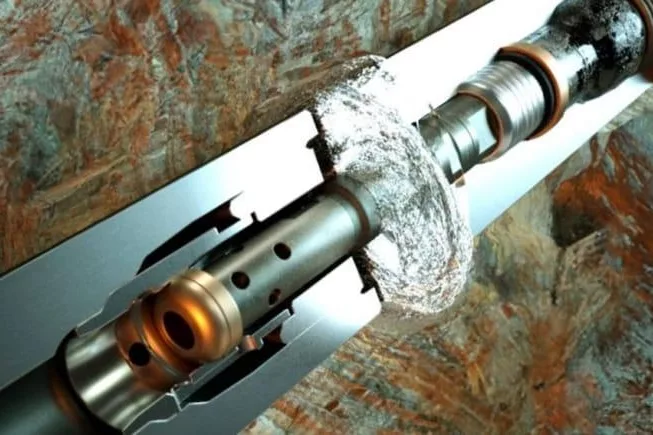

- The CBI™ tool features integral chevron-shaped blades designed to agitate any cuttings which have accumulated by settling out of the mud, and facilitates better hole cleaning

- As shown in the below dynamic flow analysis, the chevron design creates a turbulent flow in order to lift the cuttings from the lower side of the hole

Value to Client

- This CBI™ technology was effective in improving hole cleaning. This enabled faster ROP and allowed the drilling assembly to be pulled out of hole freely on elevator without back reaming or getting stuck. This in turn reduced the potential rig time spent in freeing a stuck or back reaming before the BHA was pulled out of hole

- Enables cleaner and more stable hole conditions

- Reduces circulating time

- Reduces the need for wiper trips

- Reduces trip time and improves efficiency of casing running

- Reduces torque and drag while drilling

- Reduces wear on drill string components

- Reduces frequency of stuck pipe and twist-offs

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU