Case Study

CoilHose™ technology delivers an operationally efficient solution for well-unloading

Contact

In Brief

CoilHose delivers an operationally efficient solution

Customer Challenges

- The customer had a requirement to unload a newly completed well due to a downhole ESP failure

- The customer required to unload a 1.2SG brine in a 5.5" completion to enable the well to flow prior to commencing with a well test operation

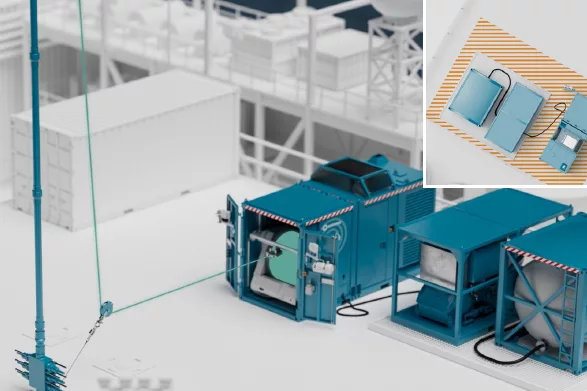

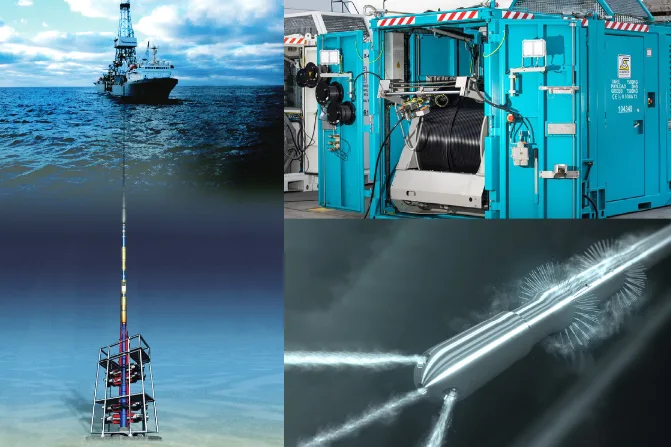

- The CoilHose system was selected as the preferred solution due to the efficiencies around rapid deployment, operational timings and smaller footprint of equipment. The system was spotted and set up on the cantilever dek of the jack up installation

- The customer had previous experience of working with the CoilHose system

Expro Excellence

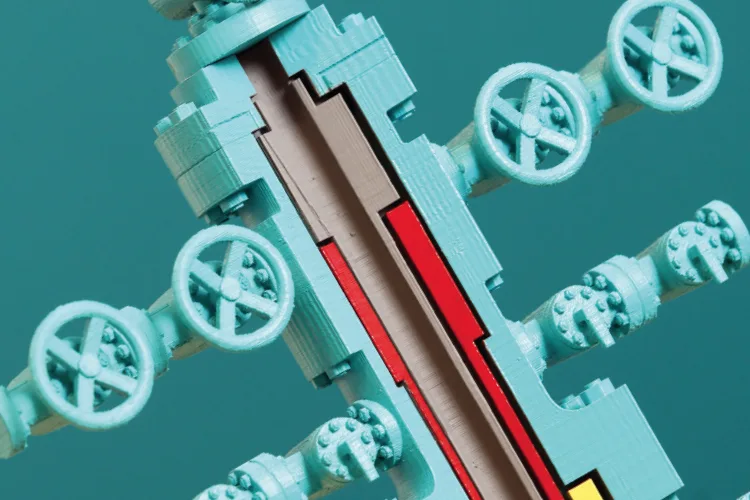

- The CoilHose system provided an alternative to conventional Coil Tubing to unload the well using nitrogen injection through the CoilHose Light Well Circulation System

- The project was planned and mobilized within 2 weeks. This included the preparation and testing of equipment, interface checks and the project design of service

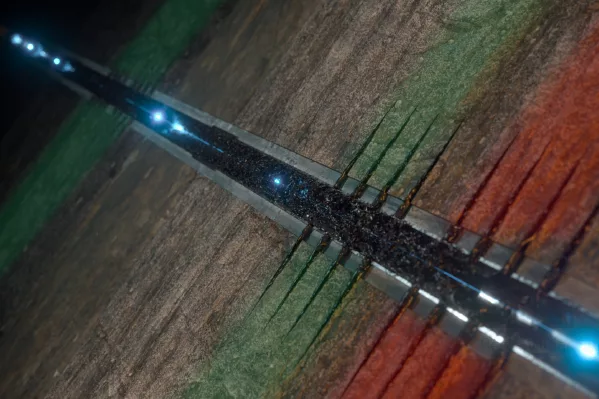

- The CoilHose system was deployed to a depth of 1000m for a duration of 8 hours while pumping at a rate of 450scfm which unloaded approximately 75bbls of brine

Value to Client

- Expro's delivery met the client's expectations with the well unloading as per the simulations conducted

- The client gained a new producing well that performed better than anticipated

- The small footprint, operational efficiency and reduced POB made planning and scheduling of the CoilHose application more straightforward versus the traditional Coil Tubing alternative

- The CoilHose system was also integrated with the well intervention package contracted by the customer

- Excellent cooperation and collaboration between Expro and the client during the project

"The CoilHose operation went really well and the Expro team optimized the operation as per our expectation in a safe manner"

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU