Case Study

Distributed Fiber Optic Sensing (DFOS) Slickline deployed for tubing to A-annulus and B-annulus leak detection

Contact

In Brief

By utlising this technology the customer had the ability to find potential leak paths through outer casing strings or through cement sheaths

Product Line

Customer Challenges

A customer in the North Sea wanted to assess the integrity of one of their wells. The requirement was to investigate an A-annulus leak, to verify the production packer integrity and to identify a separate pressure anomaly within the B-annulus

Expro Excellence

- Through in-well Fibre Optic (FO) acquisition of Distributed Acoustic Sensing (DAS) and Distributed Temperature Sensing (DTS) data, it is possible to find leak paths through outer casing strings or through cement sheaths. This is particularly relevant where leak paths and fluid movements are periodic and therefore not easily identifiable by conventional logging tools

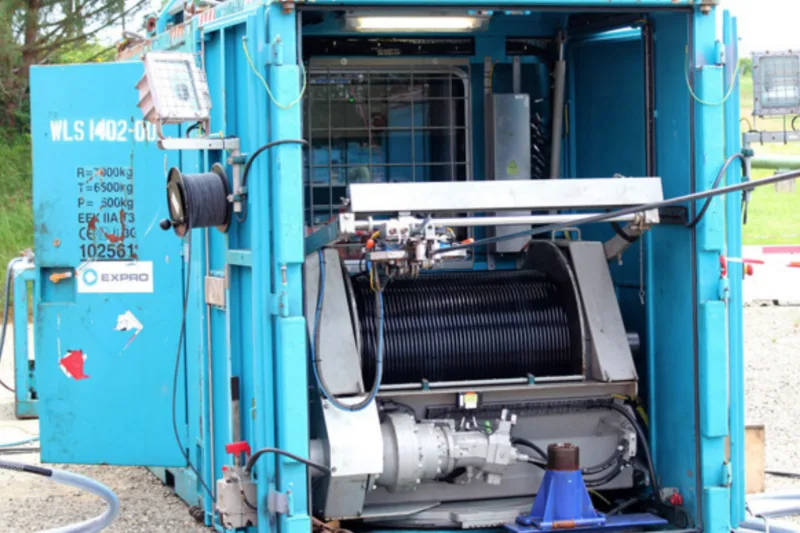

- DFOS Slickline features two single mode optical fibres encapsulated in a Slickline sheath

- The DFOS Slickline technology enabled the assement of the wells integrity through the performance of a straightforward thru-tubing well intervention

- Survey time from RIH to completion was 12.5 hours, of which 7 hours were DAS/DTS survey time

- Leak sites stimulated by injection into the B-annulus and then the A-annulus

- 7 MB of DTS data was gathered along with 1.4 TB of raw DAS data that was processed at the well site down to 2.6 GB for transmission to Expro’s onshore analysis team

- Tubing to A-annulus communication identified

- Confirmation of no leak at the packer

- Outer casing leaks in B-annulus identified

- Quick look interpretation report was sent to the customer within 2 hours for rapid decision making

Value to Client

- The DFOS Slickline intervention was performed in one third of the time it would take to investigate the well integrity issues diagnosed compared to using stationary stops with a spectral noise logging tool

- The DFOS Slickline technology enabled the identification of tubing to A-annulus communication and outer casing leaks in the B-annulus

- Identification of behind casing flow within the formation was identified

- It was confirmed that there was no loss of integrity at the production packer

- Continuous and dynamic measurement of distributed acoustic and distributed temperature data across the well length surveyed allowed tracking the direction and velocity of fluid movements during the survey

- Expro’s DFOS technology lowered the overall risk to the customer due to the reduced time rigged up on the well. This also helped reduce operational carbon emissions for the customer Fast data interpretation facilitated rapid decision making by the asset team

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU