Case Study

Effective vibration mitigation with HI TOOL™ for enhanced drilling

In Brief

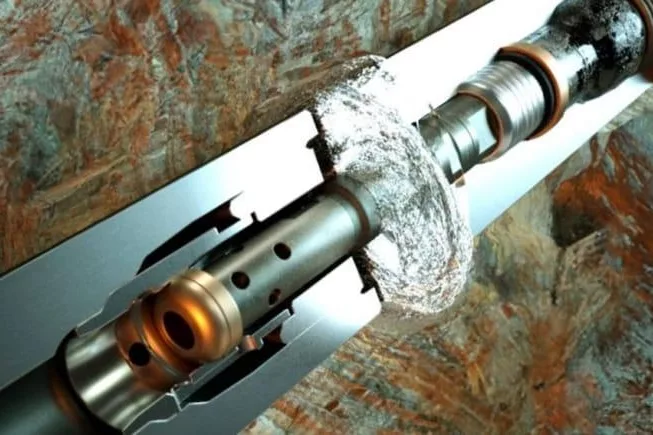

Expro's patented HI TOOL™ dampens the transmission of vibrations through it’s internal elastomeric “Anti-Vibration Rings” and spherical geared connection

Product Line

Region

Customer Challenges

- Expro was contacted by a Western Australian operator to support the 17.5” section of a project, where they experienced extremely high shocks downhole and back up to surface despite the use of conventional shock subs in the BHA

- Aside from shocks, erratic torque and stick-slip were also present and the trend continued into the 12.25” section where the desired SRPMs could not be achieved due to severe surface vibrations, preventing the BHA to drill efficiently while causing frequent inspections and repairs

Expro Excellence

- The patented HI TOOL™ dampens transmission of vibrations through it’s internal elastomeric “Anti-Vibration Rings” and spherical geared connection. Minute flex / tilt across the tool helps to decouple the BHA and dampen vibrations without having any manipulation towards drilling input energy

- Vibration generated by the drill bit, motor, and the BHA are minimally transmitted along the string, reducing loss of energy and risk of failures while improving drill string dynamics to allow better drilling performance

Value to Client

- BHA’s with HI TOOL™ drilled 3,000m across the 17.5” and 12.25” sections shoe-to-shoe through multiple shock and stick-slip prone formations seen in 3 other offset wells

- HI TOOL™ allowed application of higher SRPMs and corresponding WOB to significantly scale down Shock and Stick-Slip from Levels 1, 2 and 3 down into Level 0

- Without HI TOOL™

- Shock Peak = Frequently above 100gn

- Shock Risk = 10-15% of time in Level 1,2,3

- Stick-Slip = Average around 140% SS

- With HI TOOL™

- Shock Peak = 95% of time below 100gn

- Shock Risk = 97% of time in Level 0

- Stick-Slip = Average around 80% SS

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU