Customer challenges

- The customer required a solution to place a nitrogen cushion in the well by unloading heavy brine (9 PPG) from their 7” completion prior to perforating the well

- Drilling Rig deck space was limited as a full well test package was rigged up as part of the well commissioning project

- The use of a traditional Coiled Tubing package would have significant planning and scheduling implications for the project

Expro Excellence

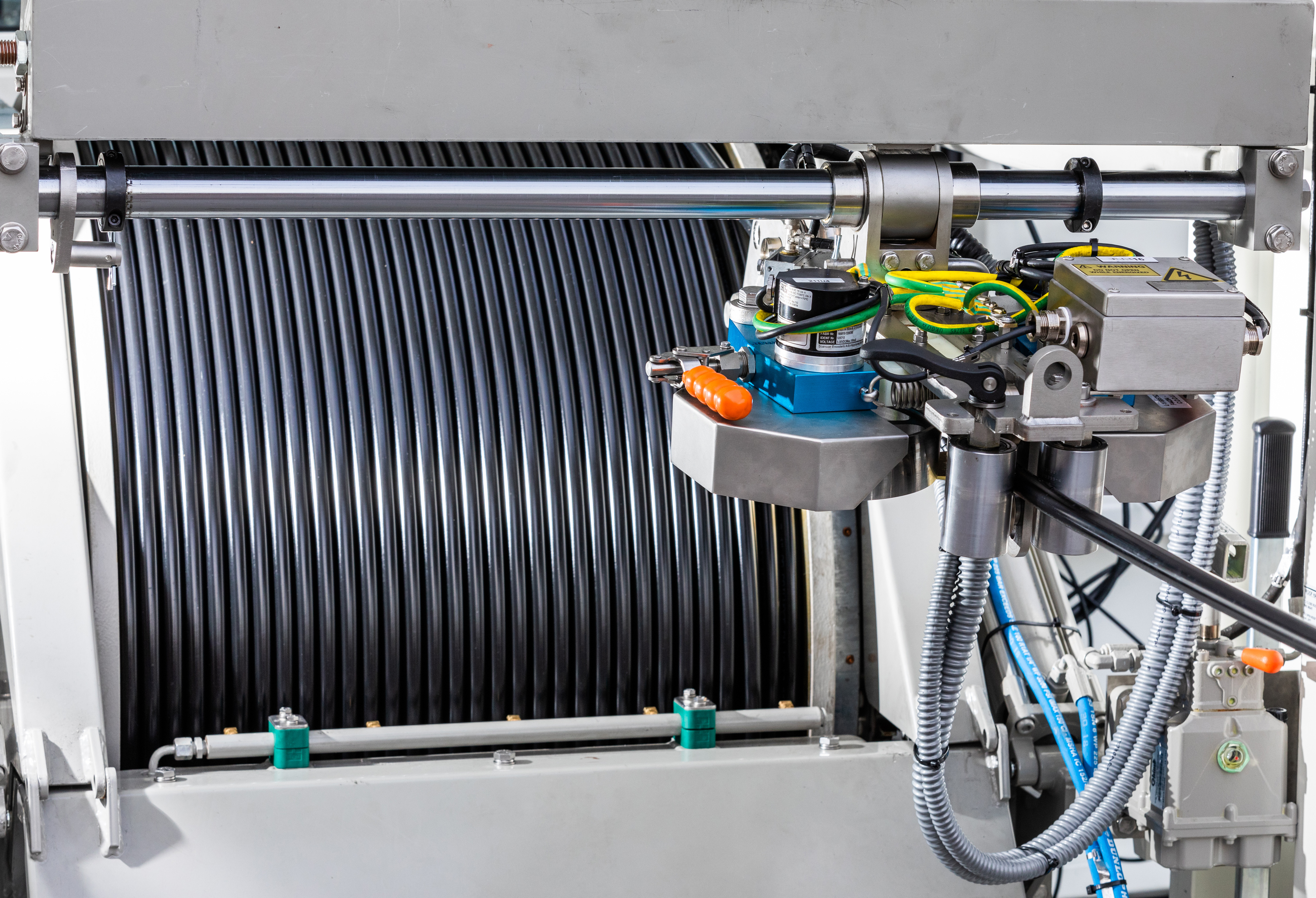

- Expro proposed the CoilHose™ Light Well Circulation System for this work scope

- The CoilHose™ Light Well Circulation System is a hybrid well intervention system that combines the operational efficiency of a wireline deployment with a capability to perform a range of nitrogen and fluid pumping applications in the wellbore

- The CoilHose™ package has a smaller footprint, fewer lifts and lower crew size vs a Coiled Tubing package

- Expro engaged with a local partner for the Nitrogen pumping aspect of the service

- The CoilHose™ system was in the well for 7 hours, during which 119 bbls of 9 PPG Brine was unloaded, whilst pumping Nitrogen at a rate of 550 scf/min

- The CoilHose™ operation was completed with no Health, Safety, Environmental or Service Quality incidents

Value to client

- The customer needed to unload their 7” completion to Nitrogen to a depth of 1,100m.MD. This objective was successfully achieved with 119 bbls of 9 PPG Brine being displaced from the well

- The customer was then able to successfully perforate their well underbalanced as per programme

- The small footprint and operationally efficient solution made planning and scheduling more straightforward versus the Coiled Tubing alternative