Case Study

Distributed Fiber Optic Sensing (DFOS) Intervention – Know the source of your sustained casing pressure

Contact

In Brief

Expro are the only company in Argentina that offers Distributed Fiber Optic Sensing (DFOS) services for well integrity evaluation

Product Line

Region

Customer Challenges

- A production well had a sustained casing pressure (SCP) issue in an outer annulus. The pressure in the Annulus reached 83 psi and when bled off produced 130bbl/day of water and associated gas production

- The well was in an area of productive farms and in the vicinity of a densely populated city, so consideration had to be taken to preserving the delicate ecological balance when conducting well surveys and intervention

- The customer needed to determine the source of the SCP and rule out communication between the deeper productive intervals and pressured Annulus

Expro Excellence

- Expro have direct contact between their technical experts and operations teams allowing quick responses, advice and support to their live operations

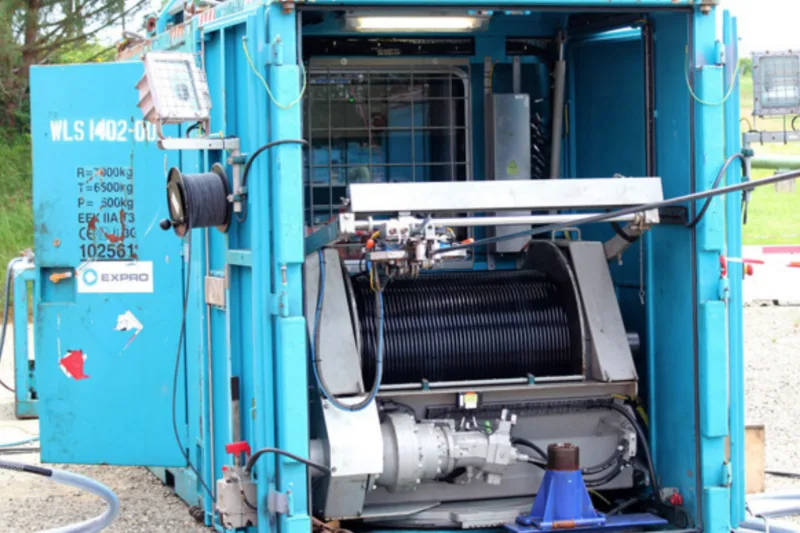

- Expro are the only company in Argentina that offers Distributed Fiber Optic Sensing (DFOS) Slickline services for well integrity evaluation

- Faced with local operational issues in deploying new technology, this was overcome by training, procedures, and cohesive teamwork

- The Expro DFOS solution achieved a survey of the whole well including a bleed and production phase in less than 8 hours

- Expro answered the primary objectives of the client within hours of gathering the DFOS data and provided added value with surveillance over the productive interval

- If Expro had not provided this solution, the customer would have had to carry out the investigation by trial and error with increased uncertainty and a higher cost implication

Value to Client

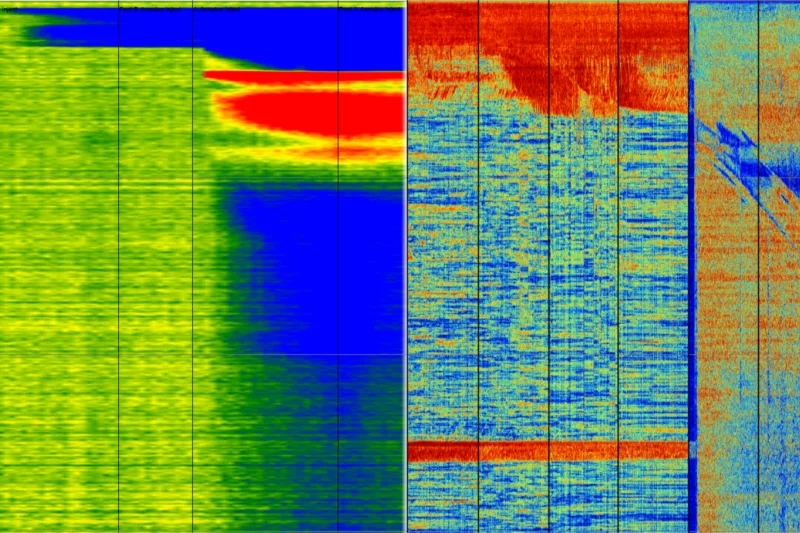

- The DFOS survey enabled the customer to locate the source of the SCP, the fluid path taken and the exact location of the fluid entry point

- In addition, this survey was also able to clearly identify the zones which were contributing to their well production, enabling the customer to conduct targeted stimulation in the future which would increase their production capacity

- The DFOS technology resulted in fewer operating hours with savings in field personnel, wireline equipment and bleed off equipment costs

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU