Case Study

Expro’s Octopoda® targets sustained annulus pressure in cement to surface application

Contact

In Brief

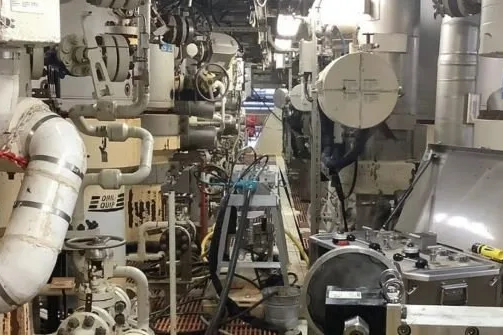

Octopoda remediation SAP-B cement to surface annulus

Product Line

Region

Customer Challenges

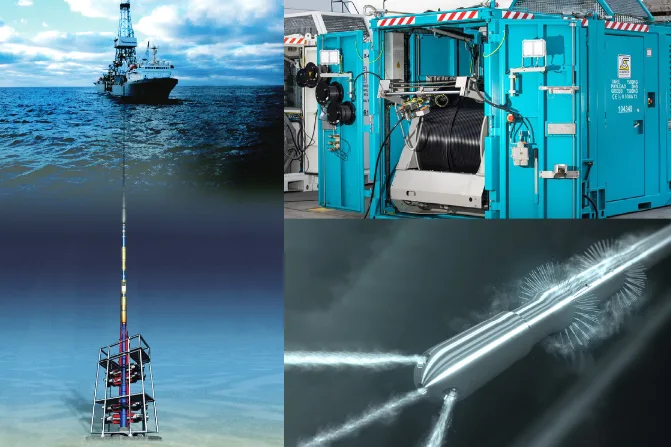

- Petroleum Development Oman (PDO) approached Expro to resolve annular gas migration through a cement micro annulus in the B annulus, preventing potential regulator-imposed abandonment

- Due to the uncertain top of cement (TOC), PDO used the Octopoda® hose to accurately determine TOC and fluid content, optimizing the resin treatment strategy

- The low injectivity rates in the annulus raised concerns that the volume above TOC might exceed the total squeezable volume. To ensure effective penetration into the cement micro annulus without surpassing the maximum allowable annular surface pressure (MAASP), resin was initially circulated into the annulus prior to commencing squeeze operations

Expro Excellence

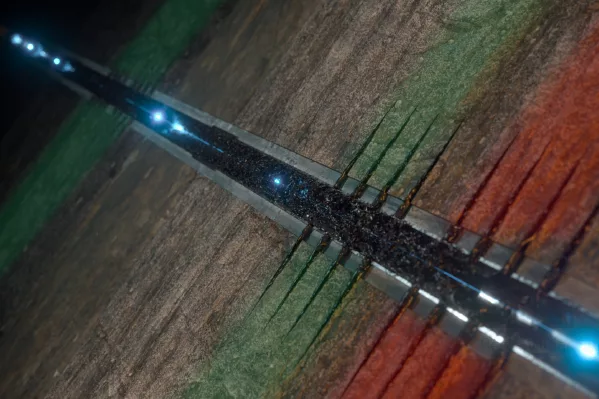

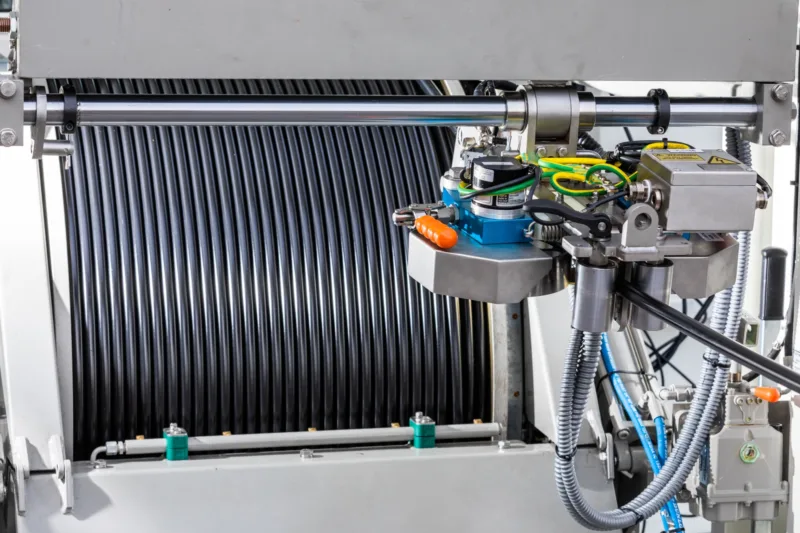

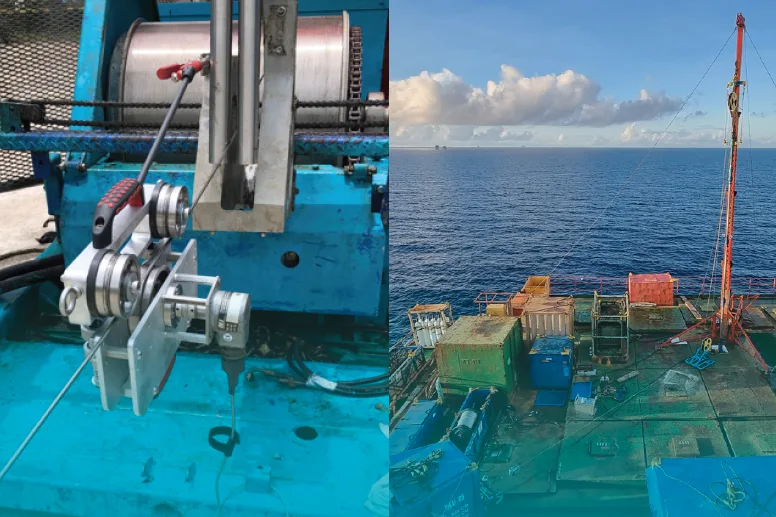

- Expro’s Octopoda® Annulus Intervention system was successfully deployed, navigating past the annulus flow ports and tagging TOC at a depth of 1.5 meters

- The annulus was conditioned with water, followed by injectivity testing. This process facilitated the optimization of the resin deployment strategy to align with

the specific annulus conditions - 30 liters of 1.05 SG resin was circulated into the annulus above the top of cement (TOC). The annulus was shut-in, and an additional 40 liters of resin was squeezed while staying below MAASP. Gate valves were flushed while maintaining squeeze pressure, and the annulus was lined back up to sustain the squeeze with water during curing. Gamma logs showed that the tracer-dosed resin penetrated to a depth of 37 meters

Value to Client

- Deploying the Octopoda® hose enabled tagging of TOC, annulus fluid conditioning, and targeted resin placement prior to squeeze operations. A tailored strategy ensured isolation objectives were achieved on the first attempt

- PDO successfully avoided the need for costly workover intervention or well abandonment, ensuring that production remained uninterrupted during the Annulus Intervention operations

- The annulus pressure was bled off, and in-flow testing confirmed complete removal of the 52bar SCP from the B annulus, allowing dispensation to be removed and production to continue

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU