Case Study

FX-600™ CRT achieves second zero-failure casing run in the Caspian Sea

Contact

In Brief

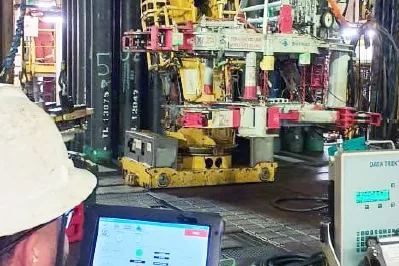

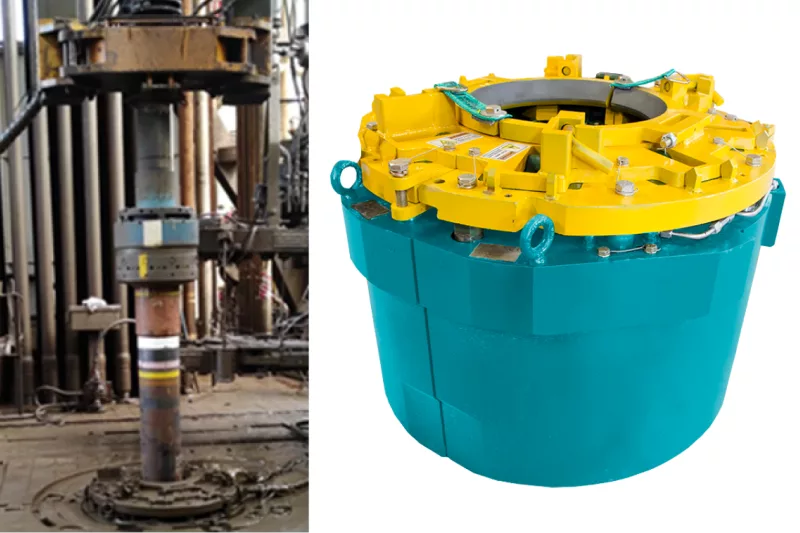

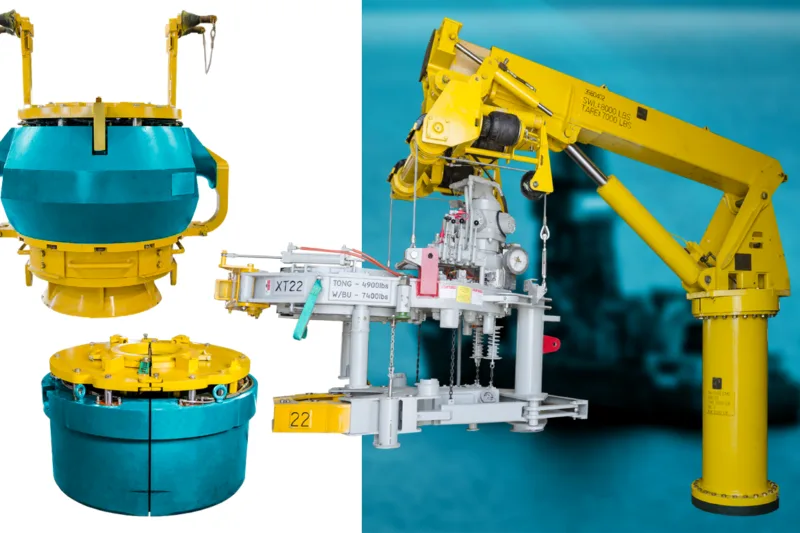

In early 2017, the Frank’s TRS FX-600™ Casing Running Tool (CRT) was successfully deployed on an offshore casing running job for a supermajor operator in the Caspian Sea.

Product Line

Expro Excellence

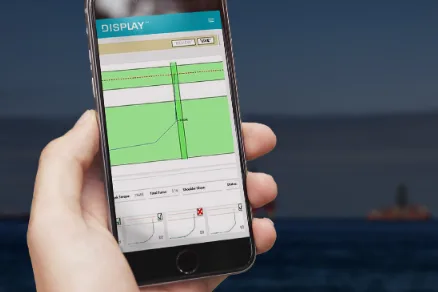

The Frank’s TRS onboard teams ran 13 3/8-inch by 13 5/8-inch casing to a total depth of 4,230 meters. Total running time for the project was 66.5 hours with zero NPT and zero node failure. The tool’s extended range capabilities meant that no slip changes were required.

Value to Client

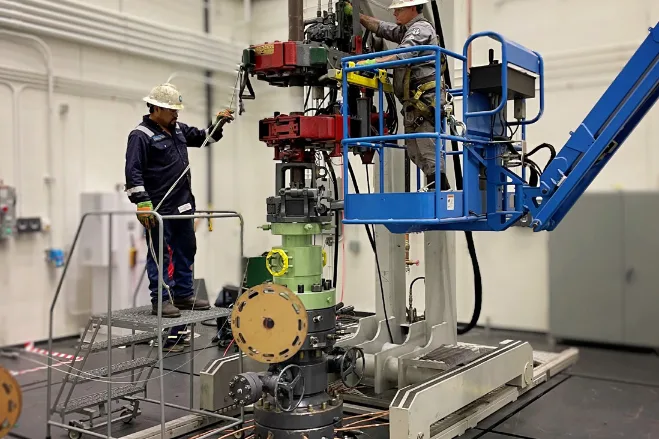

This was the second “zero-failure” casing running job in the Caspian region using the FX-600™ CRT, whose success was attributed to the preparation of the operational and quality teams and to the attributes of the CRT, which fills, rotates, circulates, and reciprocates the casing string simultaneously. In this case, downhole conditions posed some challenges that were successfully overcome, due in part to the consistent performance of the Frank’s equipment and personnel. The FX-600™ CRT improves the ease with which casing strings are run to total depth, even with troublesome or difficult hole conditions.

The scope of the Azerbaijan-based project was the ideal opportunity for Frank’s TRS to deploy our specialized equipment packages and core expertise in complex offshore completions.

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU