Case Study

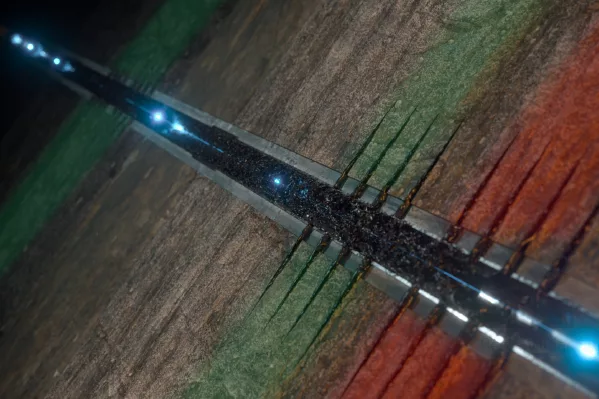

Octopoda® deployed to successfully reduce the Sustained Annulus Pressure (SAP) in the B annulus

Contact

In Brief

Expro offers a cost effective alternative to a full well workover

Product Line

Region

Customer Challenges

- Petronas Malaysia had a well experiencing Sustained Annulus Pressure (SAP) in the B annulus above the 300 psi (21 bar) limit of operating envelope acceptance

- A traditional “lubricate and bleed” operation was estimated to take 18 weeks to complete

- Well workover was not an option due to high cost

Expro Excellence

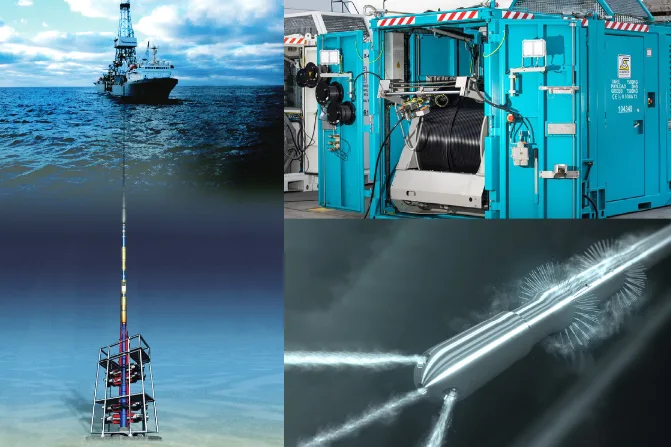

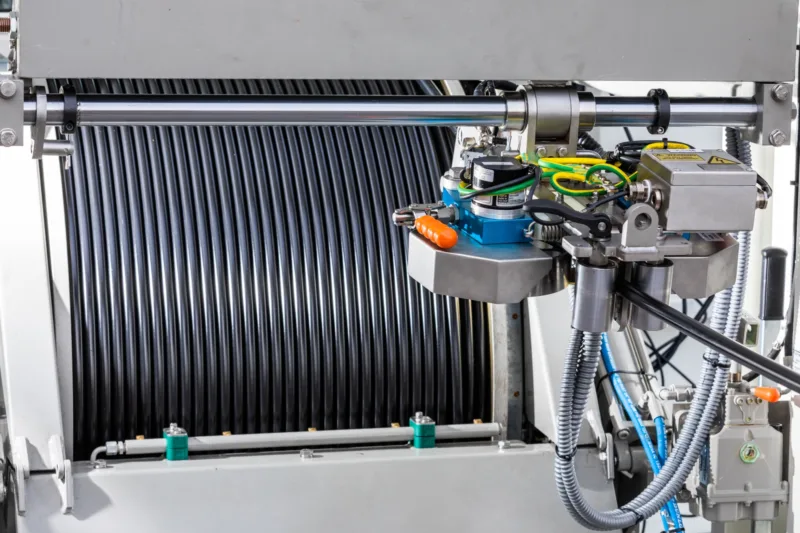

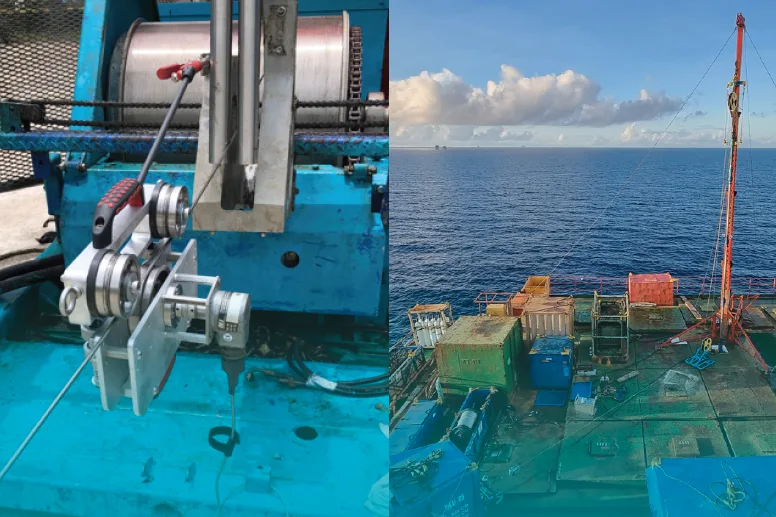

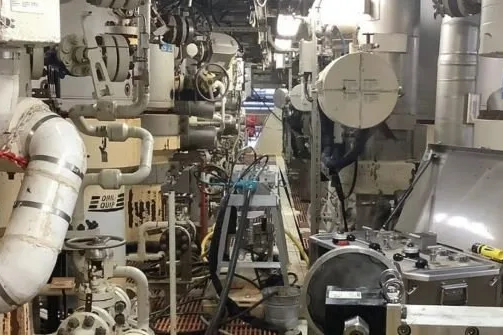

- A hydraulic intervention was carried out in the B Annulus utilizing Expro’s Octopoda® Annulus Intervention system. The objective of the hydraulic intervention was to displace the existing annulus contents with a heavy (14.8 PPG / 1.8 SG) brine

- The fluid displacement was completed in 9 days, with 65 bbls (10,300 litres) of heavy brine pumped via a 6.9 mm OD AI hose positioned at 75 feet (23 meters)

- Fluid returns were taken and monitored on the passive side of the wellhead

- The Sustained Annulus Pressure was reduced to 150 psi (10.3 bar), this enabled the well to be produced without the requirement to have a Management of Change process in place

Value to Client

- This was a cost effective alternative to a full well workover and competitor solutions

- Octopoda® enabled a significant reduction in carbon footprint compared to traditional methods

- The customer was able to regain annulus integrity within acceptable limits by swapping out the annulus contents with a heavy (14.8 PPG / 1.8 SG) brine

- This project was completed, from mobilization to de-mobilization within 3 weeks versus the “Lube and Bleed” alternative which would have taken 18 weeks to complete

- The lifetime of the casing and annulus cement was extended by the elimination of pressure cycling experienced during “Lube and Bleed” operations

- The Expro Octopoda™ solution utilized minimal personnel and equipment footprint and was powered by the Platform air supply

"We, the Petronas Well Integrity team finally managed to rectify the sustained annulus pressure issue for this well after a series of past trials with other technologies and methods.”

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU