Customer challenges

- A major operator identified key challenges and operational risks when planning to run 9-7/8” Casing in a 12-1/4” open hole section of an extreme Extended Reach Drilling (ERD) Well

- With a planned Measured Depth (MD) of over 25,000ft, and a step-out ratio of 2.15, the mixedweight 9-7/8” Casing string was set to be a record length

- The risks of differential sticking were high, especially if the string were to remain stationary in open hole for any amount of time, so equipment would be required that minimized static time

- The maximum pickup weight was expected to reach 1,350,000lbs (675 tons), and based on offset data from similar Wells, it was predicted that the string would need to be washed down through key formations of the open hole

- To mitigate these risks Expro were challenged to deliver a heavyduty equipment package that provided the ability to make-up, fill-up, circulate and run the mixed weights of Casing and the fullbore landing string, in singles and stands, all without the need to change out handling equipment

Expro Excellence

- Expro provided specialist equipment and services that enabled all objectives to be achieved

- Due to the complexity of the job many scenarios were analyzed and calculations were made during the planning stage, in relation to die efficiency, slip crush modeling, reduced hoist capacity while circulating, casing stretch and mixed torque application

- Seven technologies with proven track records were used to maximize safety and efficiency:

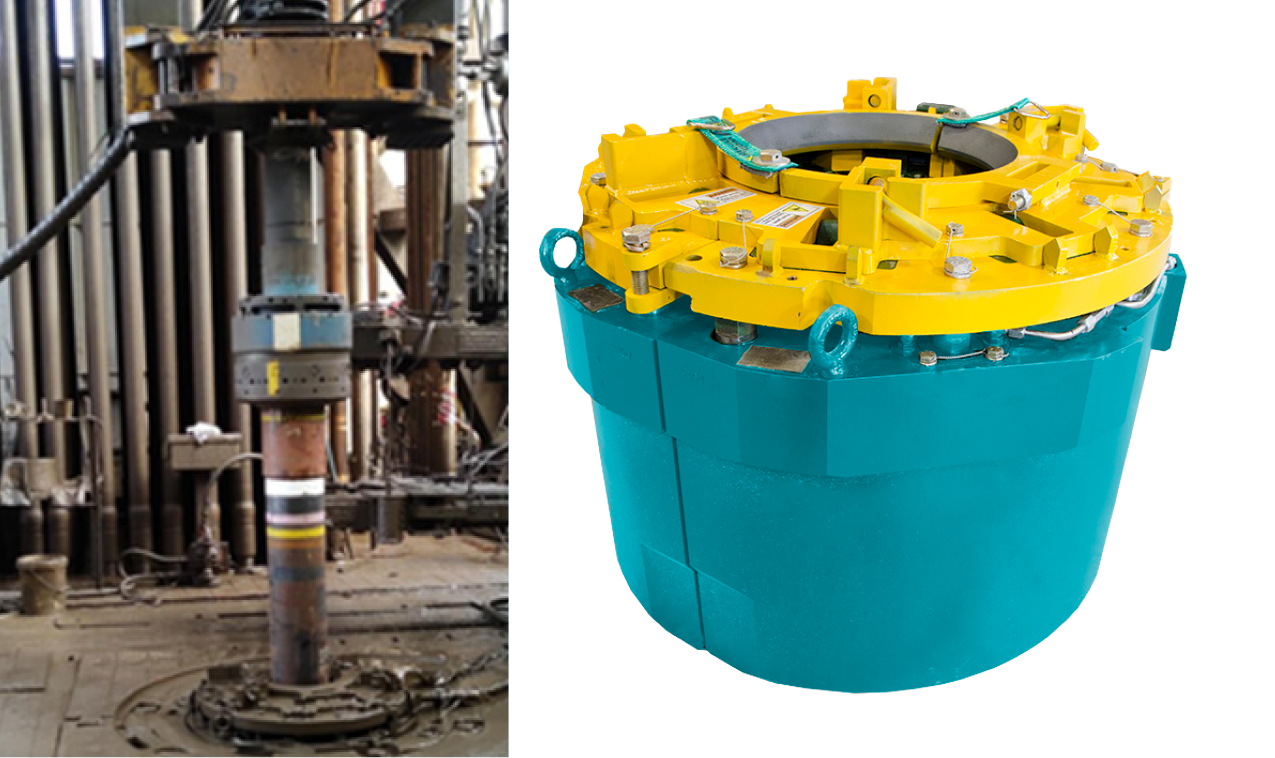

- CRTi Casing Running Tool

- 14” x 1,000t Split Bushing Spider

- RTS-ST160 Cassette Tong

- 14 3/8” Zero Power Tong

- Tong Pusher Arm Mk-3 (TPA)

- Data-Trek® FLEX Computers

- DISPLAY™ Digital Application

- The CRTi2-8.63 750HC handled the 1,350,000lb (675 ton) of ‘pick-up weight’ with ease whilst providing the capability to circulate at 942 lpm (249 gpm) and 55 bar (800 psi) whilst running in hole to get the string to TD with no issues

- The CRTi2-8.62 enabled the driller to activate the tool without the need for any umbilical hanging in the derrick, and when paired with Expro’s 14” 1000ton Split Bushing Spider, provided the heavy-duty, simple and reliable package the customer required for this high-risk, high-valve operation

Value to client

- Operations were completed with zero incidents, zero NPT and zero rejected connections during critical path or rack back operations

- The 9-7/8” casing string was successfully run to a final setting depth of 25,247ft on the first attempt, following a consistent Wellbore path of 69° inclination after exiting the 13 3/8” shoe

- Due to the last 5,000ft of casing taking three days to washdown, the equipment choice and contingency planning was critical to enable successful manipulation through troublesome open hole zones

- Forty stands of casing that were assembled and racked back while drilling the 12-1/4” section were run at strategic points in the operation on the customer’s Super A Class Jack-up rig to minimize stationary time in open hole and therefore minimize the risk of differential sticking

- The combination of Expro’s proprietary technologies, meticulous planning, preparation, and execution reduced and eliminated risks to personnel, equipment, and operations

- The casing run demonstrated Expro’s continued delivery of first-class service quality to a long-term customer of over 23 years