While the long-term future of exploration and appraisal (E&A) drilling is unclear, current practices must undoubtedly change.

As we accelerate into the energy transition, we should take stock of existing systems, technology and processes available in the oil and gas industry. It is right that super majors, IOCs and NOCs have committed to reducing their net carbon footprints, but the targets set are ambitious. They will require innovation, dedication and a willingness to challenge the traditional methods of conducting operations. There is an opportunity to utilise established technologies in fresh and novel ways to help drive those changes.

A key focus area that draws significant international interest is E&A and new field developments, especially offshore. There are various conflicting reports on the composition of future energy sources and how oil and gas fits into the picture alongside the long-term solution of renewables. A recent study by Rystad in December 2020 indicated that upstream players would need to invest 3-5 trillion USD of capex to meet a global oil demand through to 2050 and that undiscovered resources would make up ~25% of the total oil supply in three decades. This, however, is in stark contrast to a special report released in May 2021 by the International Energy Agency (IEA), which states that to reach global net-zero emissions by 2050 and stay within 1.5°C target for global warming, oil demand must decline and therefore no new oil and gas developments are required.

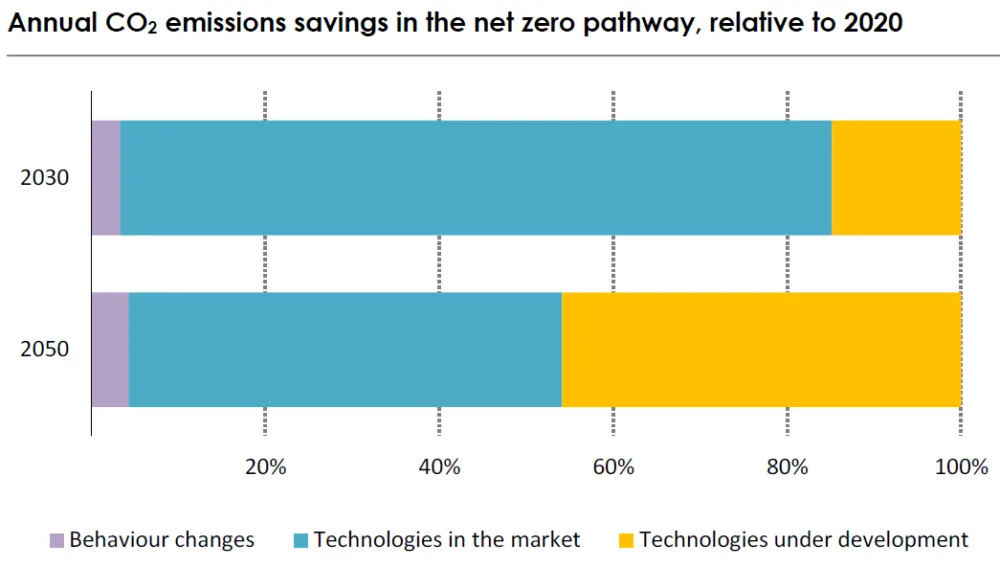

The IEA report goes on to say that existing technologies are critical in the path to achieving net-zero carbon, with them holding the key to a staggering 82% reduction in CO2 emissions between now and 2030 and 50% before 2050. While the report focuses on critical areas such as hydrogen, bioenergy, low-carbon electrification, and carbon capture, utilisation and storage (CCUS), the upstream oil and gas sector has an opportunity to capitalise on this thinking by looking within to help achieve the goals that have been set.

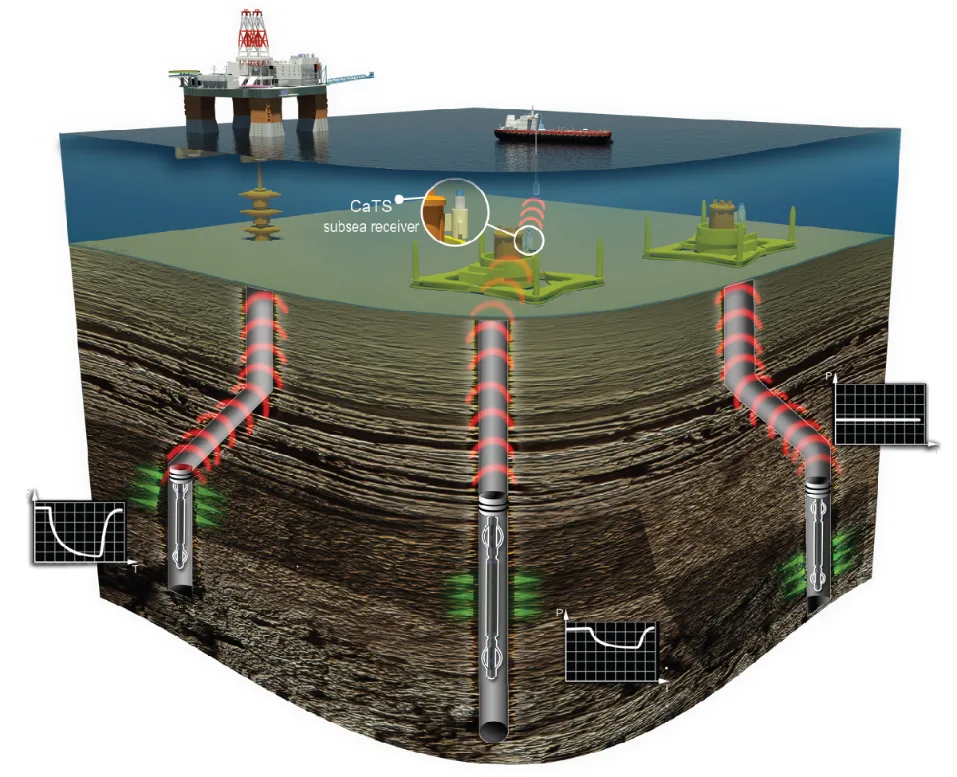

The catalyst for change in E&A will likely be government targets and regulations. One existing technology, in particular, may hold the key to cutting rig time, reducing the appraisal well count and optimising field developments. Installing Expro’s CaTS™ permanent wireless gauges in abandoned and suspended wells enables operators to continue monitoring the reservoir for up to ten years after the rig has left location. The pressure and temperature data are sent wirelessly to a seabed receiver, ready to be uploaded on demand. This data can only be recovered using wireless technology and it allows operators to validate subsurface models and make informed decisions regarding the future potential of the field. With over 20 years of track record and more than 50 systems installed in the Advanced Reservoir Testing (ART) application, the technology has industry acceptance as a cost-effective, low-carbon monitoring solution. The wide adoption of the technology demonstrates the confidence operators have in the system and underlines Expro’s market-leading position.

Having access to this data can reduce reservoir uncertainties and shape the outcome of future activity within the field. This insight gained may lead to fewer wells being drilled, which would streamline any development plan and significantly reduce costs, but importantly, reduce the carbon impact of the campaign.

A key question to address in any exploration program is whether to test the well. Traditional methods dictate that well testing is the best method of appraising reservoirs, however, this is environmentally and politically sensitive. Alternative techniques such as mini-DSTs and closed chamber tests negate the need to flow to surface but have limitations. An obvious solution would be to use the produced hydrocarbons, which reduces emissions and generates revenue. While this is achievable for oil, it’s harder to store produced gas, however some gas-for-power systems exist to optimise rig electricity usage. While utilising the resources is a neat solution for the environment, logistics and equipment requirements mean the approach is often not economically viable for short term tests.

Wireless gauges can be used as part of a greener appraisal strategy by converting abandoned and suspended wells into high-value observation assets. The system will monitor for interference whilst flowing other wells in the field. This approach limits the number of tests and maximises data acquisition while adding value to written-off assets, saving costs and lowering the associated CO2 emissions. Where a well is tested, wireless gauges can shorten the time the rig is on location while drastically extending the data collection period from the pressure build-up.

As it is not seemingly feasible to eliminate all carbon emissions from drilling activities, we must work together and focus on operational efficiencies to reduce them where possible. Incremental changes throughout the well’s lifecycle can lead to significant improvements at the end of a project. Emerging technologies can help with this objective, but their acceptance as part of the solution is likely to be influenced by budgets, attitudes and geographic sensitivities.

We are at a critical stage in preserving our planet and, we, as an industry, have a responsibility to drive change wherever possible. Whatever the long-term future holds for hydrocarbon exploration, we must conduct all operations with the environment in mind. Technology can help reduce the carbon intensity of necessary appraisal tests and optimise upcoming field developments, but will require operators and regulators to adopt and believe in them as part of the long-term solution.

Additional information:

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU